Liquid level meter

A liquid level gauge and liquid level technology, applied in the field of liquid level gauges, can solve the problems of difficult wiring of liquid storage tanks, long wiring construction period, and high cost of liquid level gauges, so as to improve accuracy and flexibility, avoid installation and construction costs, The effect of free wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0042] It should be noted that like numerals and letters denote similar items in the following figures, therefore, once an item is defined in one figure, it does not require further definition and explanation in subsequent figures. Meanwhile, in the description of the present application, the terms "first", "second" and the like are only used to distinguish descriptions, and cannot be understood as indicating or implying relative importance.

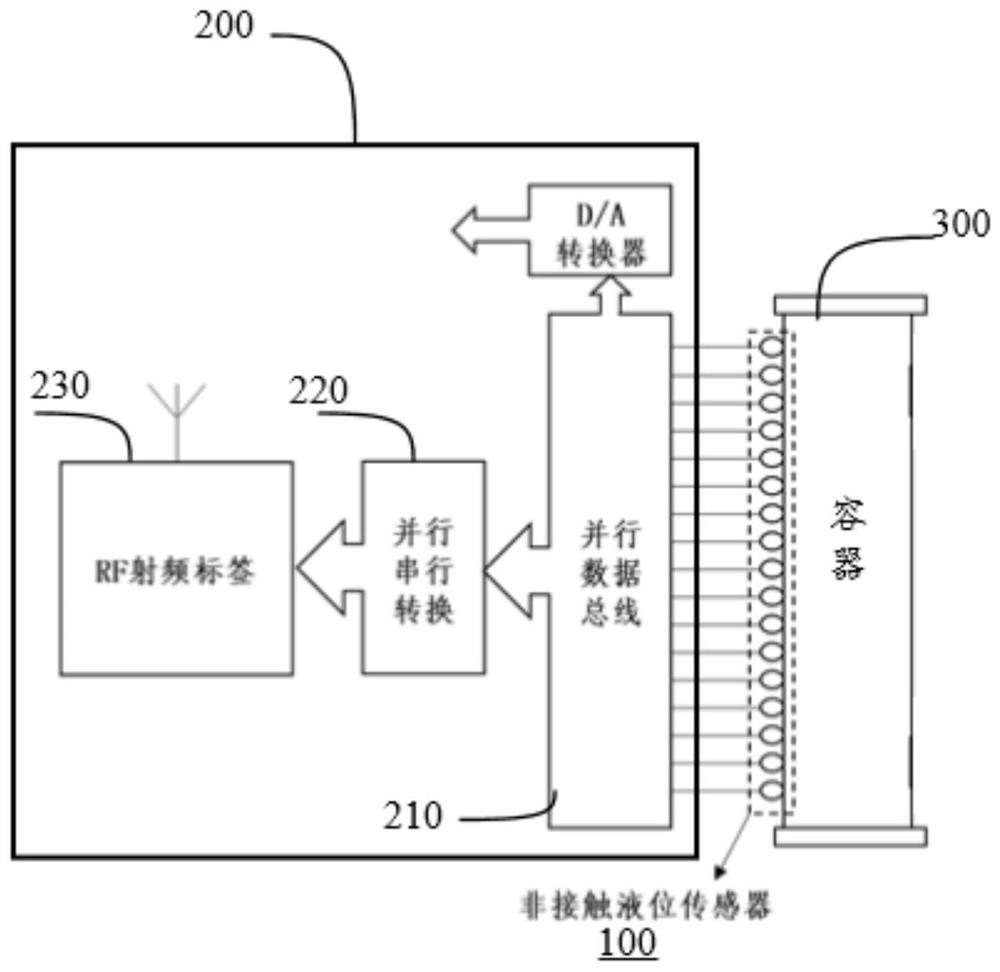

[0043] In order to solve the defects of some related technologies in the background technology, some embodiments of the present application provide an intelligent digital liquid level gauge, which realizes liquid level through a plurality of non-contact liquid level processing sensors (for example, non-contact liquid level switches). For continuous measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com