The method of adjusting the gap between the scraper and the screen of the cuttings dryer

A dryer and screen technology, which is applied in the direction of dryers, drying solid materials, drying, etc., can solve the problems of increased gap between the spiral drum scraper and the screen, and reduced processing capacity, so as to improve operating efficiency and cost Low, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

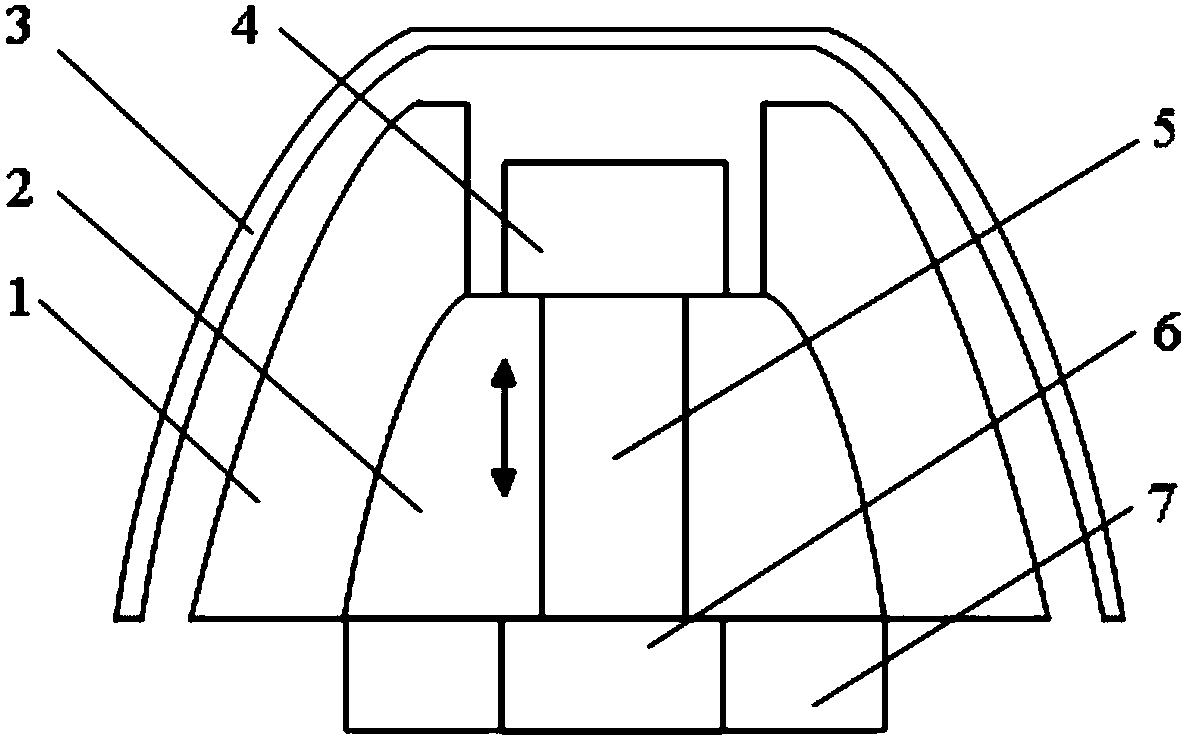

[0019] refer to figure 1 The structure of the object to be regulated by the method of the present invention is to include a power mechanism 6 fixedly installed in the support frame 7, the power mechanism 6 is in transmission connection with the moving assembly 5, and the moving assembly 5 passes through the shaft center hole of the spiral drum 2 and is connected at the front end. A fixed component 4 is installed, and a plurality of scrapers 1 are evenly (distributed) installed on the outer surface of the spiral drum 2, and a screen 3 is arranged on the periphery of the scraper 1 at a predetermined distance, and the rear end (fixed end) of the screen 3 is fixedly connected to the support frame 7 .

[0020] The moving component 5 is used as the implementation unit for the axial movement of the screw drum 2, and can move the axial position of the screw drum 2; the fixed component 4 can keep the screw drum 2 at a set position in the axial direction of the moving component 5 , to ...

Embodiment 2

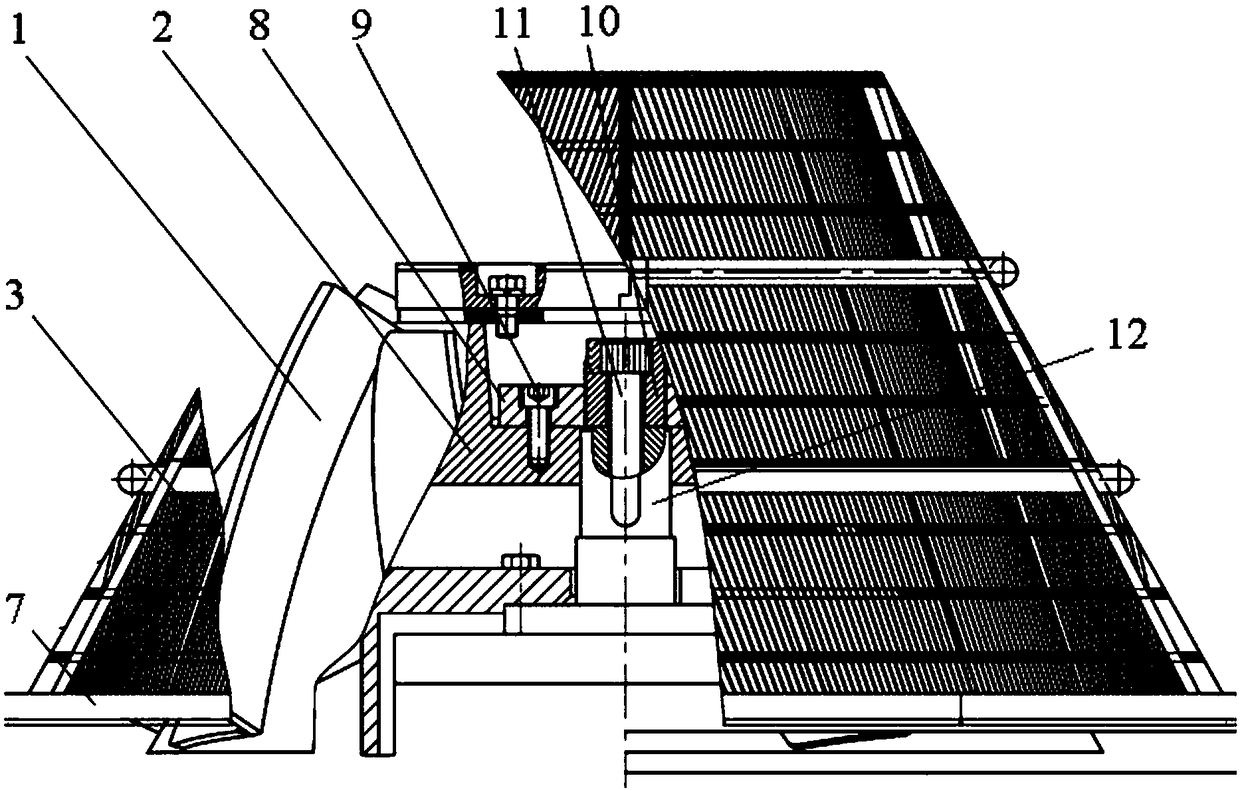

[0027] refer to figure 2 , the installation structure of the adjustment object (drum scraper and screen of the cuttings dryer) includes a drive shaft 12 fixed on the axis of the support frame 7, and a hollow guide block is fixedly installed in the center hole of the front end of the drive shaft 12 through bolt Ⅱ11 10. The outer circle of the transmission shaft 12 is set with a screw drum 2 through the key, and a plurality of scrapers 1 are fixedly installed on the outer surface of the screw drum 2; A plurality of bolts I9 are fixedly connected to the flange 8; in addition, the periphery of the scraper 1 is provided with a screen 3 at a predetermined distance, and the rear end (fixed end) of the screen 3 is fixedly connected to the support frame 7 to ensure that the screen 3 is always in a static state.

[0028] In this structure, the helical drum 2 realizes the axial adjustment along the drive shaft 12 by moving along the direction of the keyway, the flange 8 moves and locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com