Cigarette block height detecting and controlling device

A technology of height detection and control devices, which is applied in the field of tobacco machinery, can solve the problems of material interruption during shutdown, difference in the net length of cigarette packs, and easy material blocking, etc., and achieve the effects of reducing tobacco leaf crushing, ensuring continuity, and eliminating material blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

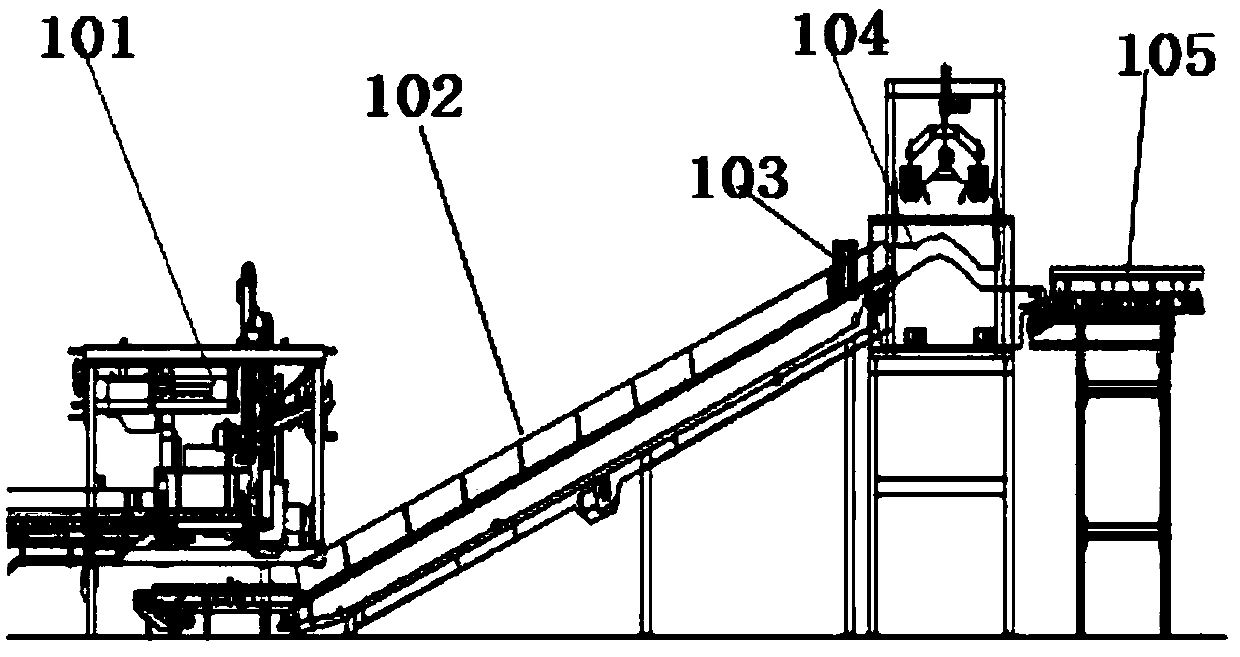

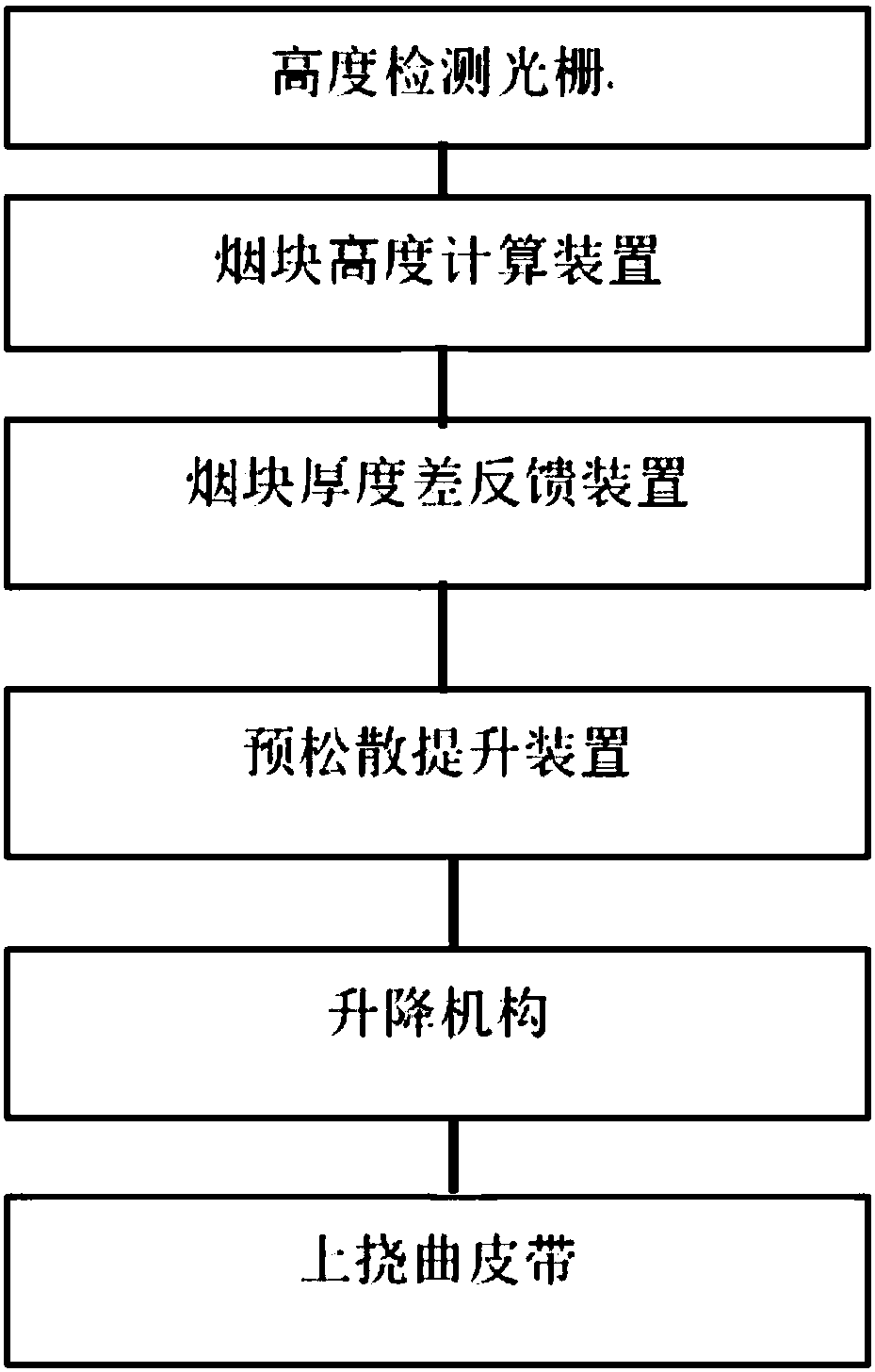

[0035] A cigarette block height detection and control device, which includes a height detection grating, a cigarette block height calculation device, a cigarette block thickness difference feedback device, a lifting mechanism, and a pre-loosening lifting device;

[0036] - Height detection grating, at least a pair of height detection gratings are installed axially symmetrically on both side plates of the electronic scale belt at the feeding end of the pre-loosening equipment, and the height detection grating detects the height of the cigarette block;

[0037] - the cigarette block height calculation device, the cigarette block height calculation device is connected to the height detection grating, the cigarette block height calculation device processes the height analog signal of the cigarette block detected by the height detection grating, and obtains the data of the real-time detection of the height of the cigarette block;

[0038] - a feedback device for the difference in th...

Embodiment 2

[0042] A cigarette block height detection and control device, which includes a height detection grating, a PLC, a lifting mechanism, and a pre-loosening lifting device;

[0043] -Height detection grating, at least one pair of height detection gratings is installed axially symmetrically on both side plates of the electronic scale belt at the feeding end of the pre-loosening equipment, the height detection grating detects the height of the cigarette block, and the height detection grating is connected to the PLC;

[0044] - The pre-loose lifting device is connected to the PLC, and the pre-loose lifting device calculates the proper height of the lifting mechanism according to the data of the cigarette block thickness difference feedback device and judges whether the lifting mechanism is rising or falling;

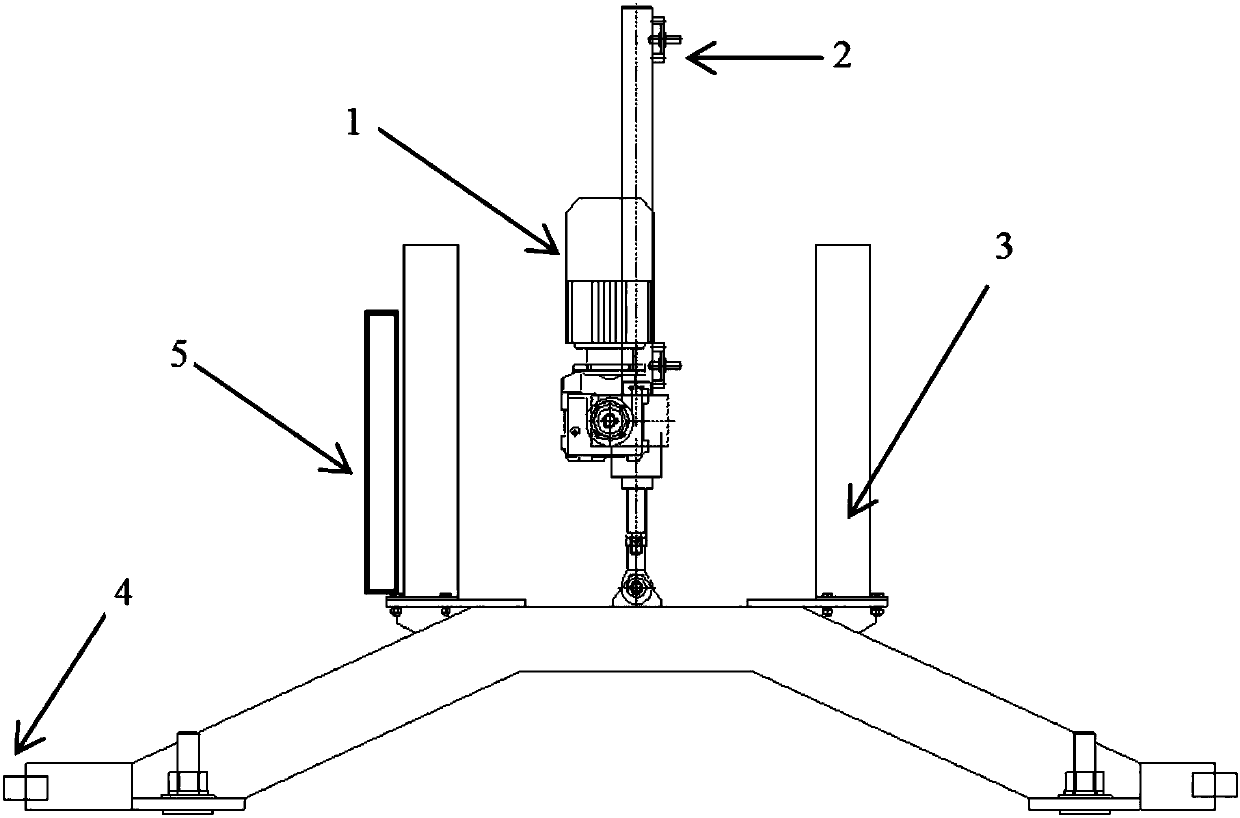

[0045] - Lifting mechanism, the pre-loosening lifting device is connected and automatically controls the lifting mechanism to move up and down. The lifting mechanism includes a...

Embodiment 3

[0047] Different from Embodiments 1 and 2, the lifting mechanism further includes a motor, a hanger, a guiding mechanism and a displacement sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com