Self tightening flow passage sealing structure

A sealing structure and flow channel technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of reducing the service life of the sealing structure, easy to scratch the sealing structure, and corrosiveness of the sealing structure. and other problems, to achieve the effect of reduced manufacturing cost, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

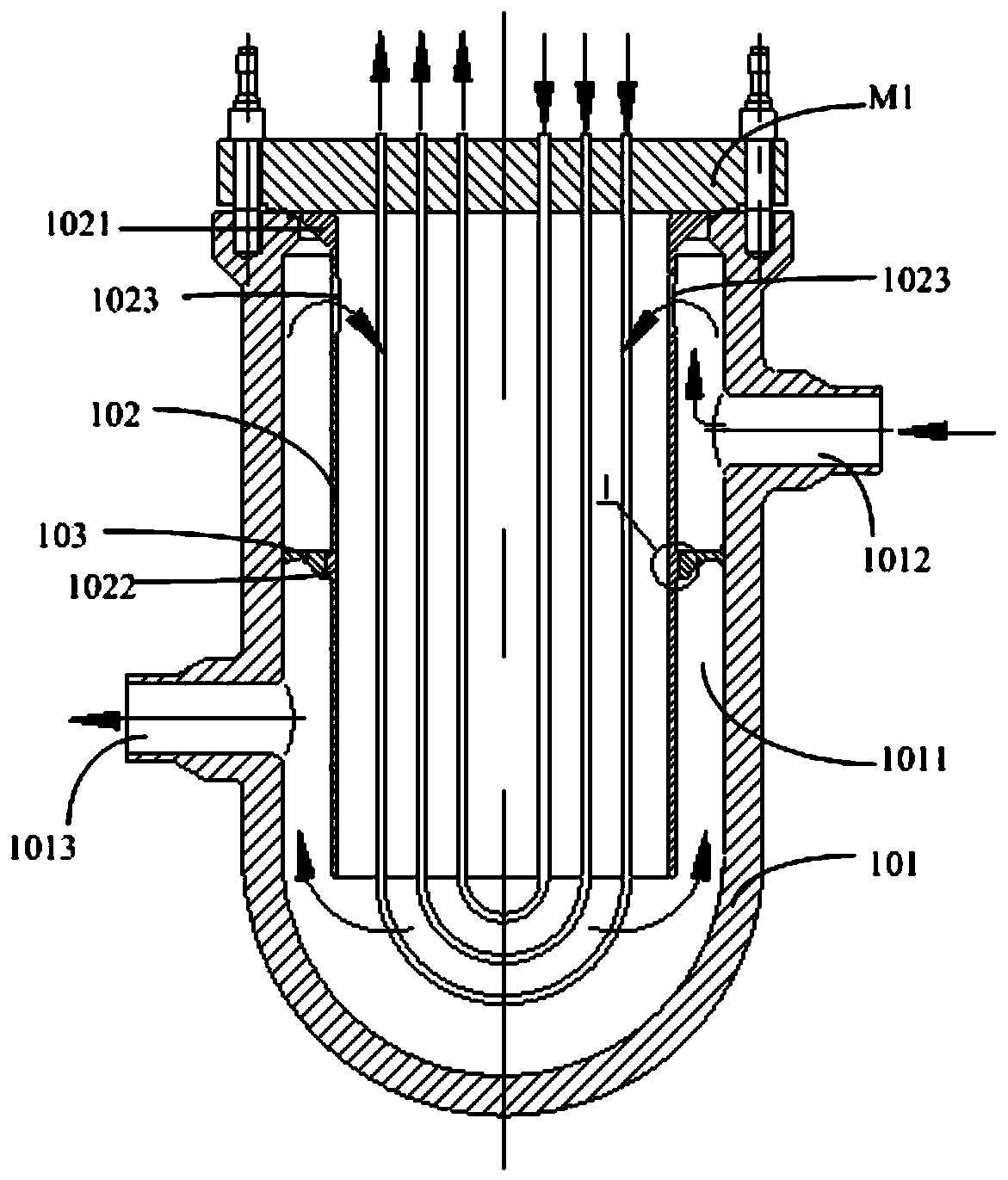

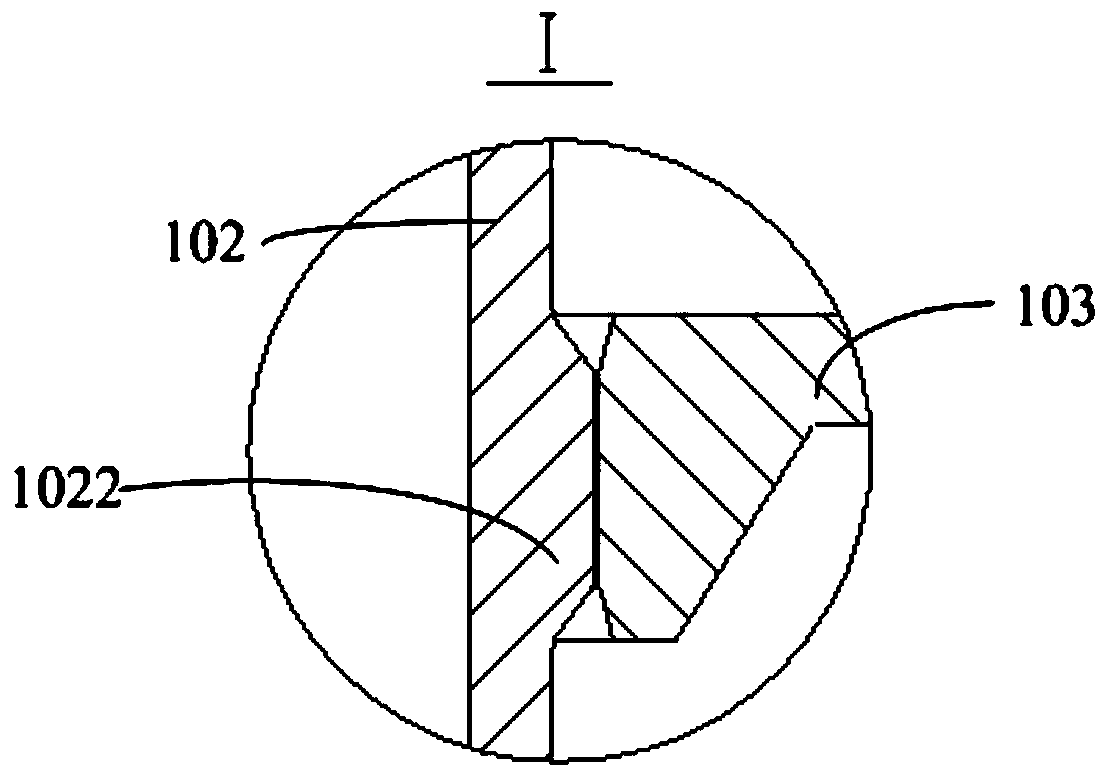

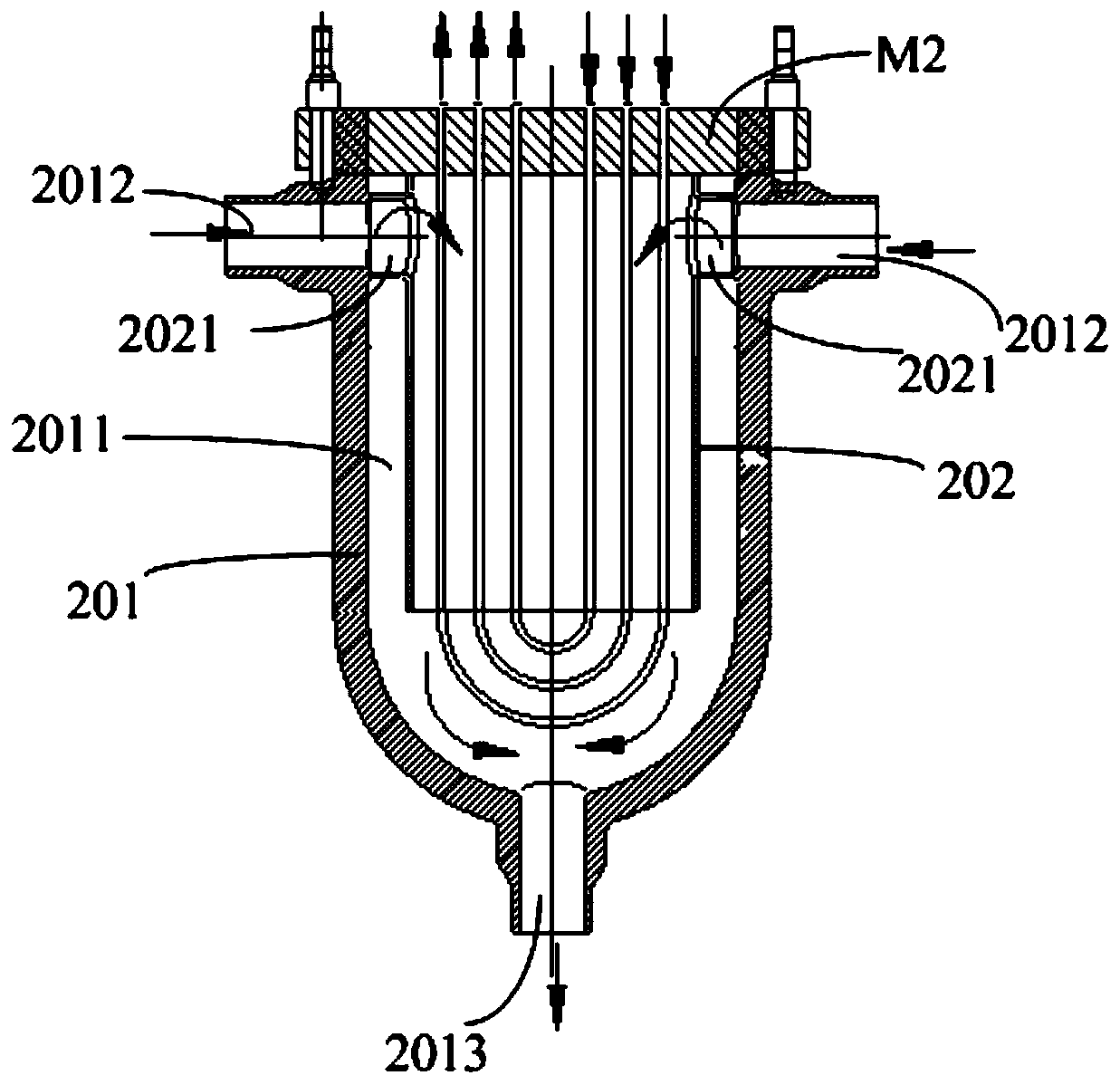

[0034] Such as figure 1 with figure 2 As shown, in Embodiment 1 of the present invention, a self-tightening flow channel sealing structure is provided, which is arranged inside the equipment or pipeline, including a housing 101, a sleeve 102 and a partition 103; wherein,

[0035] The casing 101 is fixed to a preset support platform (not shown) on the equipment or pipeline through the cover plate M1, on which a cavity 1011, an inlet 1012 for liquid (such as water, liquid metal, etc.) The discharge outlet 1013; wherein, the cavity 1011 is closed or has a hollow cavity with an opening facing the cover M1; the inlet 1012 is arranged close to the cover M1, and passes through the side wall of the housing 101 to communicate with the cavity 1011; The outlet 1013 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com