Wind tunnel test platform inclined angle mechanism

A technology of wind tunnel test and platform, which is applied in the field of rotor wind tunnel test, can solve the problems such as the lack of understanding of the aerodynamic characteristics of the new rotor, and achieve the effect of simple structure, low production cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

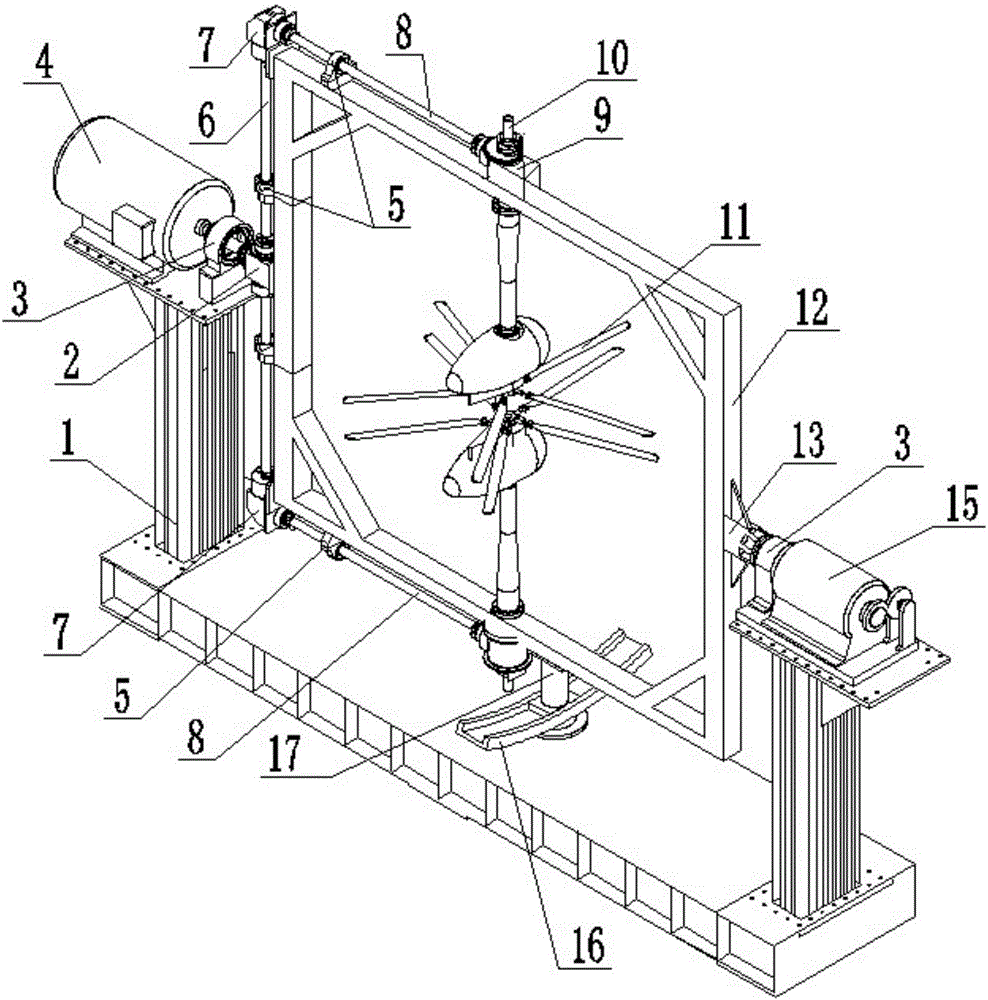

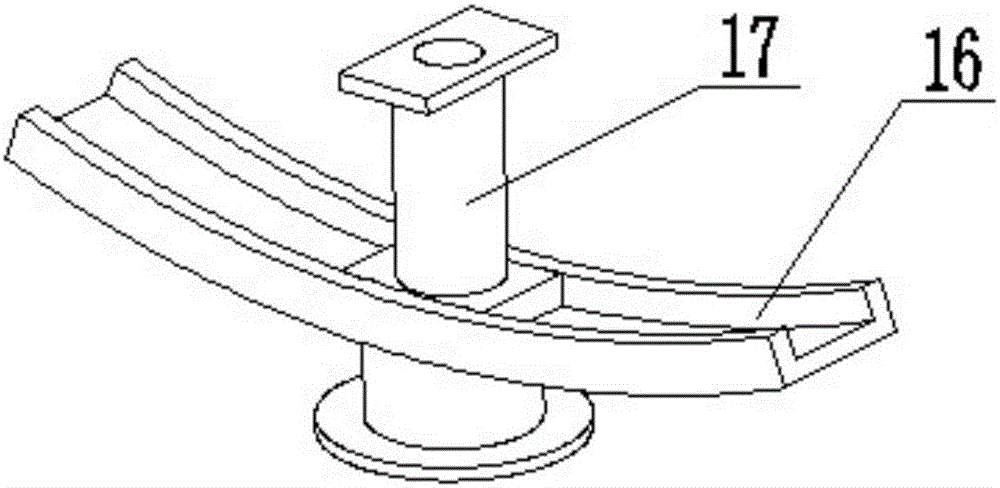

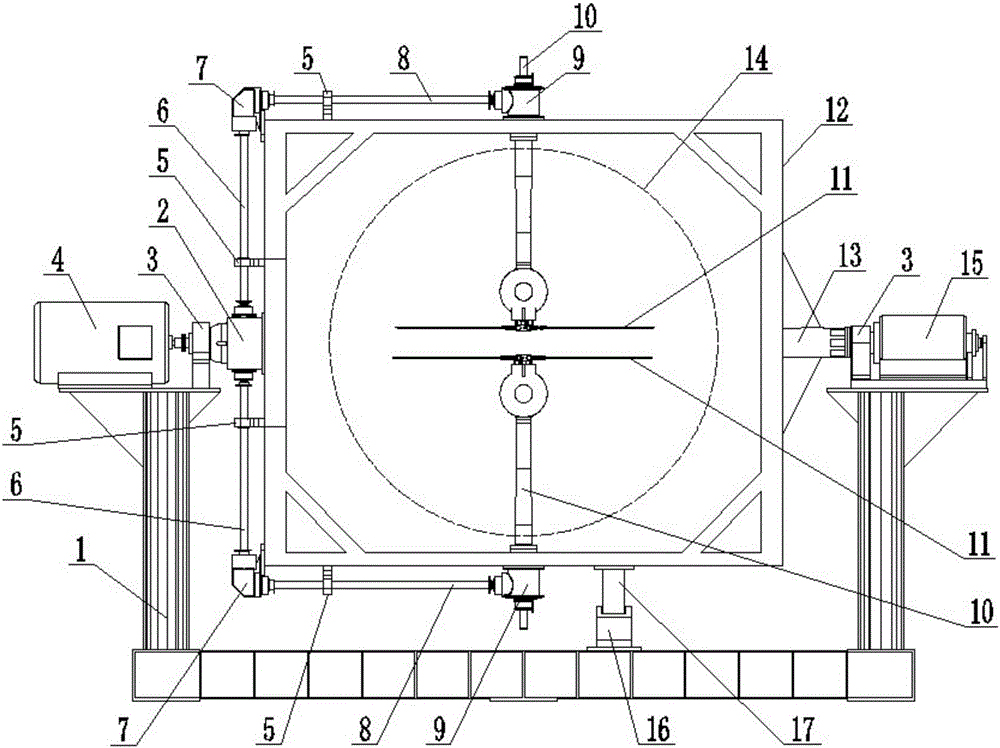

[0030] like figure 1 , image 3 The shown wind tunnel test platform inclination mechanism includes a rotor mounting frame 12, a torque motor 15, a slide rail 16 and a slider 17, and the rotor mounting frame 12 is formed opposite to the rotating shaft support 3 through the left rotating shaft 24 and the right rotating shaft 13 respectively. Rotationally connected and movably connected on the platform 1 , the slide rail 16 is fixedly connected with the platform 1 , and the slider 17 is fixedly connected with the rotor mounting frame 12 . The main motor 4 is fixedly installed on the left column of the platform 1, and the main motor 4 drives the rotor 11 in the rotor installation frame 12 to reverse synchronously, and the torque motor 15 is fixedly installed on the right column of the platform 1. The motor 15 drives the rotor mounting frame 12 to swing relative to the stand 1 through the right rotating shaft 13, the output shaft axis of the main motor 4 coincides with the output ...

Embodiment approach 2

[0035] Compared with Embodiment 1, what described slide rail 16, slide block 17 adopted is electromagnet, and, when torque motor 15 controls rotor mounting frame 12 to stop moving relative to platform 1, described slide block 17 and The sliding rails 16 form mutual adsorption through magnetic force. When the torque motor 15 controls the rotor mounting frame 12 to start moving relative to the stand 1, the electromagnetic attraction between the slider 17 and the slide rail 16 is released, so that the relative movement between the slider 17 and the slide rail 16 is smoother . Others are the same as Embodiment 1.

[0036] After the slide rail 16 and the slide block 17 adopt electromagnets, by powering them off, the magnetic attraction between the slide rail 16 and the slide block 17 can be released, so as to reduce the energy consumption of the torque motor 15. 1, it is more conducive to improving the level of energy saving and consumption reduction.

Embodiment approach 3

[0038] Compared with Embodiment 1 and Embodiment 2, rollers are installed at the bottom of the slider 17, and when the slider 17 moves relative to the slider 16 within the limited range of the slider 16, the slider 17 passes through the rollers and the slider 16. There is rolling friction between them. Others are the same as Embodiments 1 and 2.

[0039] Compared with Embodiments 1 and 2, since the sliding block 17 forms rolling friction between the rollers and the slide rail 16, compared with the sliding friction, the friction loss is lower, so that not only the sliding block 17 and the sliding rail 16 The relative movement between them is smoother, and it is more conducive to improving the level of energy saving and consumption reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com