Force/Position Controllable Flexible Actuator

A flexible drive and controllable technology, applied in the field of robotics, can solve problems such as difficulty in meeting requirements and inability to guarantee the output force of the drive, and achieve the effect of protecting the system itself and relieving internal forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

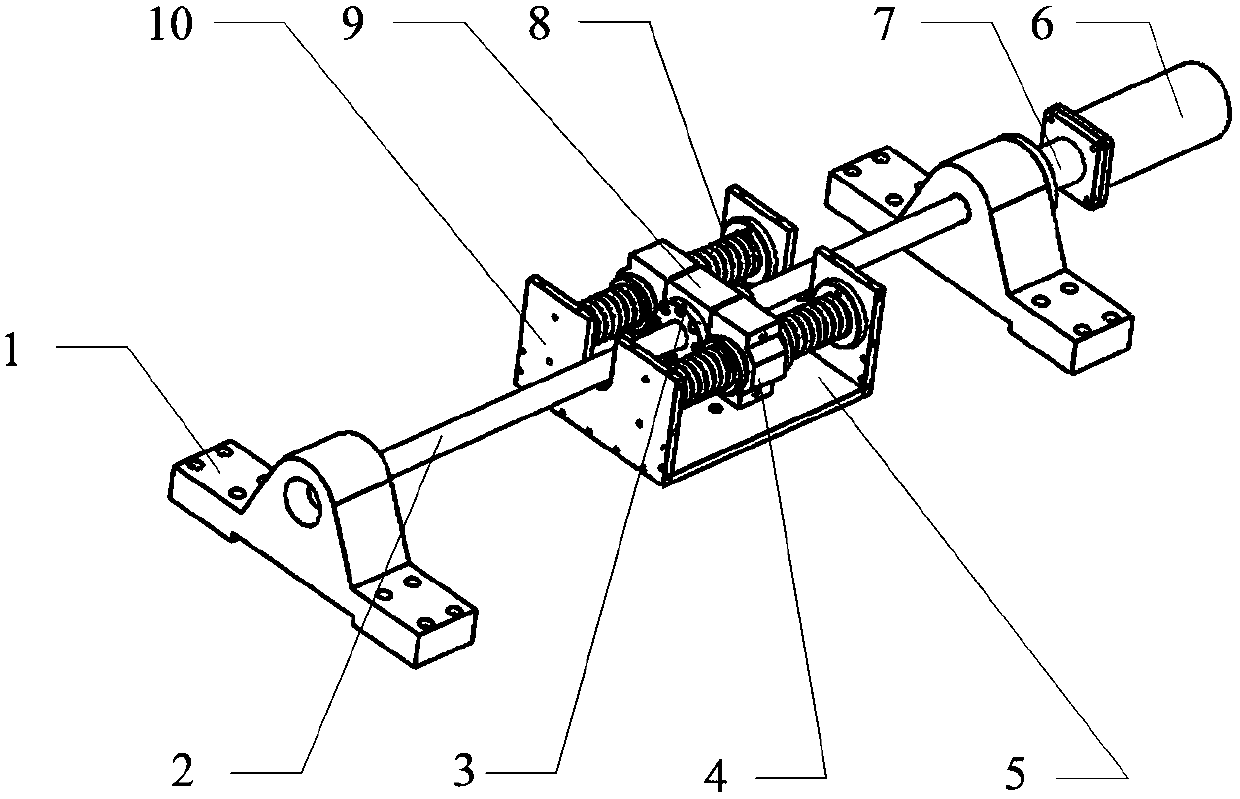

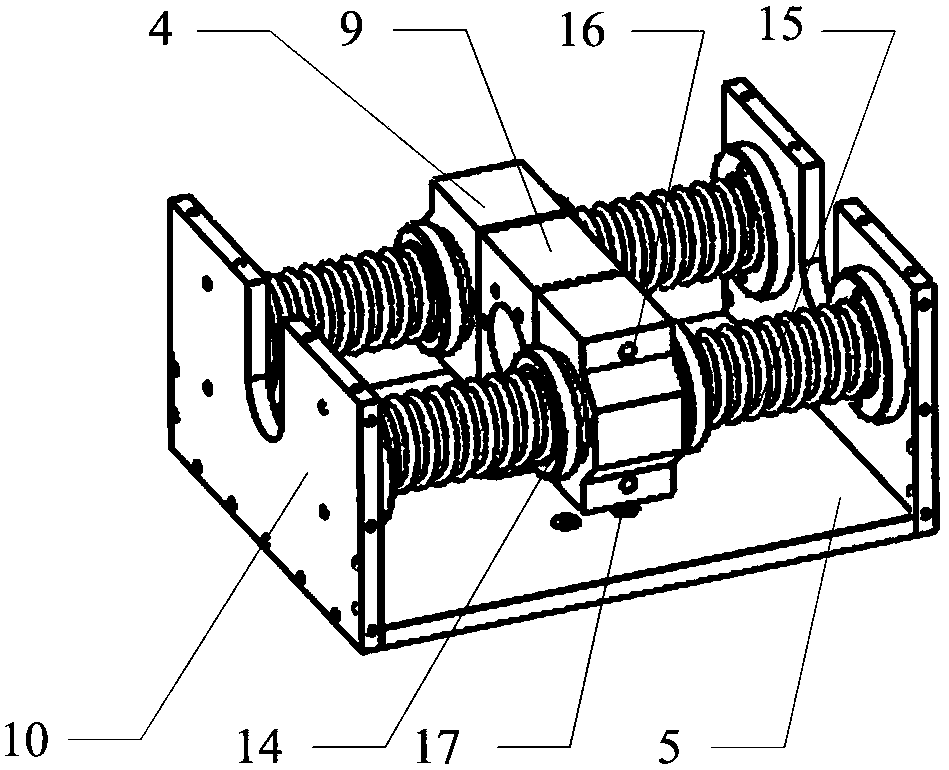

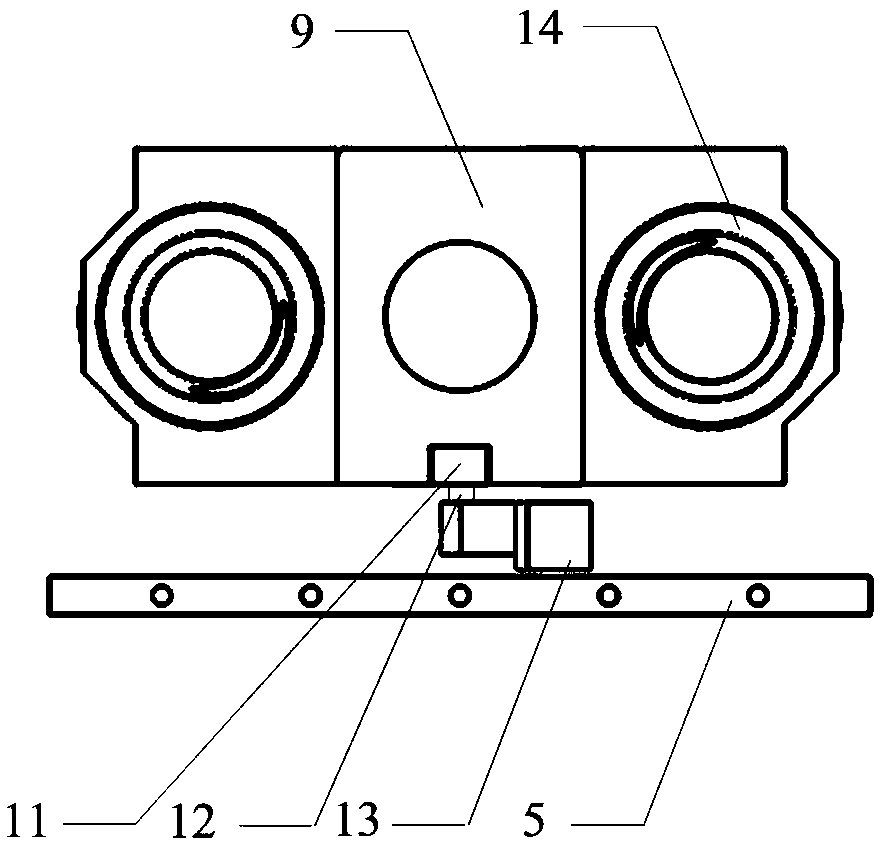

[0020] exist figure 1 , figure 2 , image 3 with Figure 4 In the schematic diagram of the present invention shown, the driving device includes a bracket, a lead screw, a servo motor, a shaft coupling, a nut connector, a long bolt A, a sliding bearing, and an optical shaft. Two identical brackets 1 are respectively provided with through holes, and the two ends of the screw 2 pass through the through holes of the two brackets respectively, and one end of the screw extends to the outside of the brackets, and is connected with the output shaft of the servo motor 6 through the coupling. Shaft 7 is connected. Insert the nut connector 9 on the lead screw, one side of the nut connector is provided with a nut 3, the nut is threadedly connected with the lead screw, and the two ends of the nut connector are respectively connected with a sliding bearing 4 through a long bolt A16. An optical shaft 15 is respectively plugged into each sliding bearing, and both ends of the optical shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com