Wide-temperature-range high-precision shafting structure

A high-precision, wide-temperature-range technology, applied in the directions of bearing components, shafts and bearings, and rigid supports of bearing components, it can solve the problems of inaccurate angle measurement and suffocation, and achieve the effect of reducing output interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Through the following description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, any components or technical features Changes to the definition and / or formal but not substantive changes to the overall structure should be regarded as the scope of protection defined by the technical solutions of the present invention.

[0013] Example:

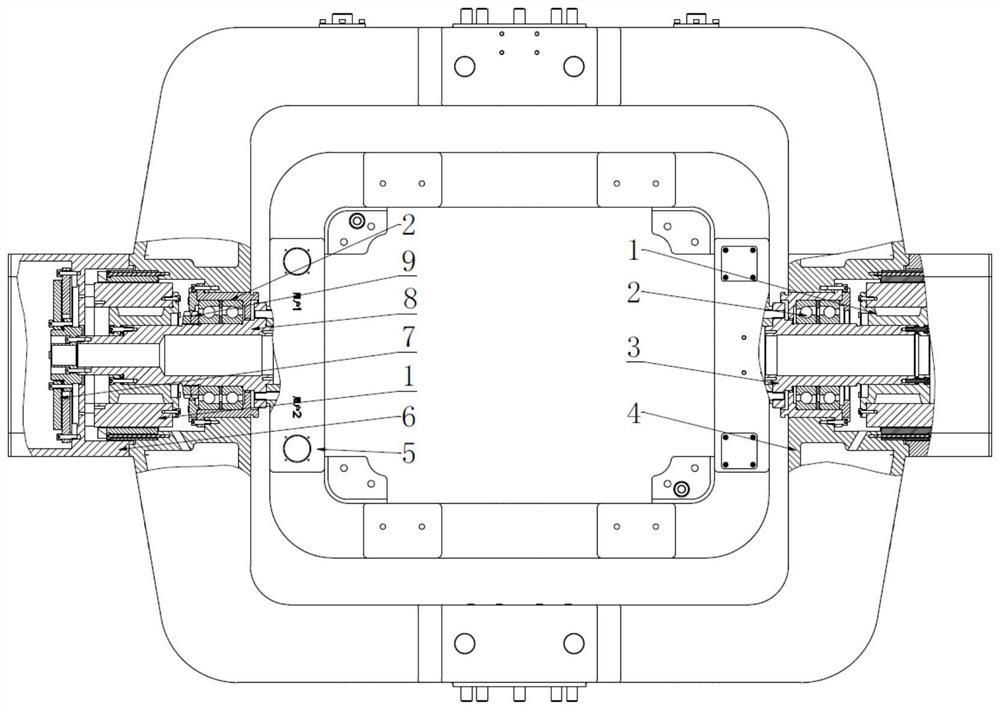

[0014] The invention comprises a DC torque motor assembly (1), an angular contact ball bearing assembly (2), a right shaft (3), a middle ring frame (4), an inner ring frame (5), an angle measuring bracket (6), and a circular induction synchronizer Angle measuring assembly (7), left shaft (8), lock nut (9); it is characterized in that the inner ring frame (5) is connected with the left shaft (8) and the right shaft (3), and through the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com