Stepping cutting device

A cutting device, step-by-step technology, applied in the direction of fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of prolonged cutting time, high tension, affecting cutting efficiency, etc., to improve cutting efficiency and convenience. Removal and installation, easy cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

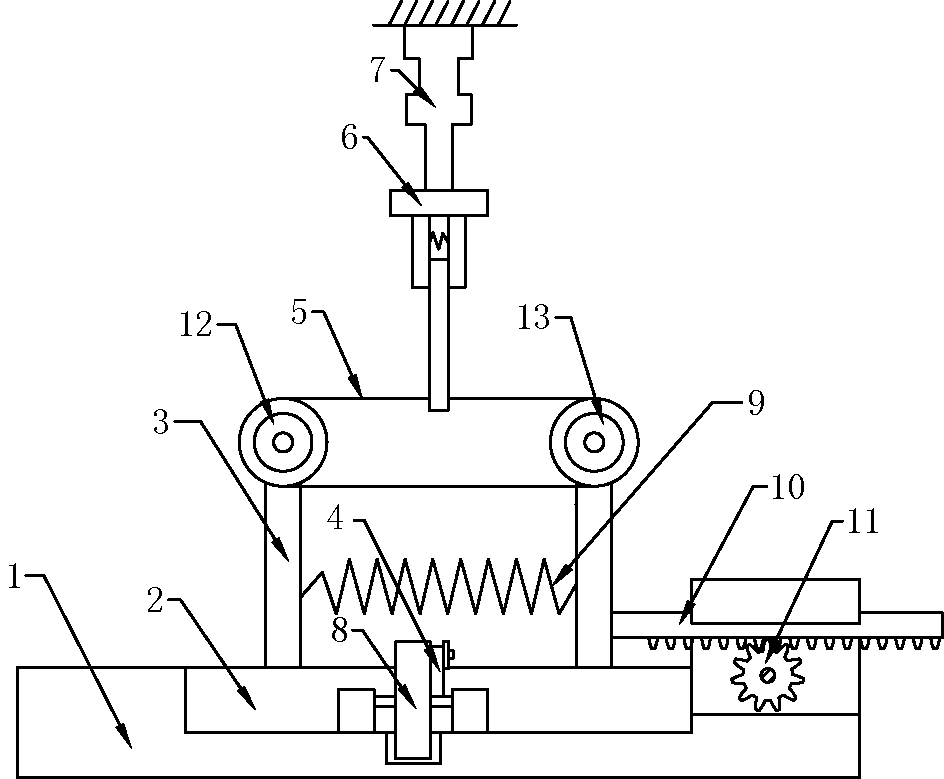

[0014] The reference signs in the drawings of the description include: frame 1, base 2, fixed rod 3, connecting rod 4, diamond wire 5, claw 6, cylinder 7, turntable 8, spring 9, rack 10, gear 11, drive Roller 12, driven roller 13.

[0015] Example basic reference figure 1 Shown: a step-by-step cutting device, including a frame 1 and a diamond wire 5, the frame 1 is provided with a relative driving roller 12 and a driven roller 13, and the diamond wire 5 is wound between the driving roller 12 and the driven roller 13 , the driving roller 12 is connected with a third stepping motor, the frame 1 is connected with a base 2 that slides back and forth, the left side of the base 2 is connected with a fixed rod 3, and the driving roller 12 is connected to the top of the fixed rod 3 in rotation, and the base 2 is connected to the right side of the fixed rod 3. The side is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com