Auxiliary forming assembly for mold, mold and forming method and assembly method for mold

An auxiliary molding and mold technology, applied in the field of mold forming and assembly, and mold, can solve the problems of complex components, high equipment cost, and the mold structure cannot be used to form battery boxes, etc., to achieve simplified components, simple control, and good practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Based on the above technical features, the main functions of the mold structure with auxiliary molding function and its molding method and assembly method of the present invention will be clearly presented in the following embodiments.

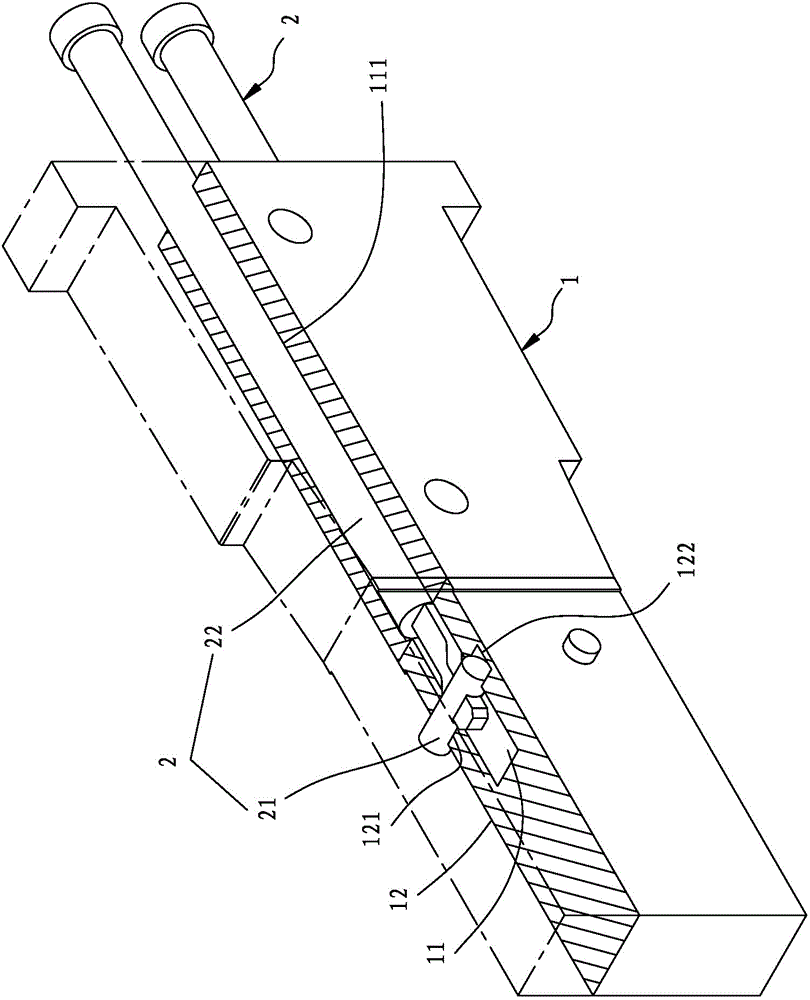

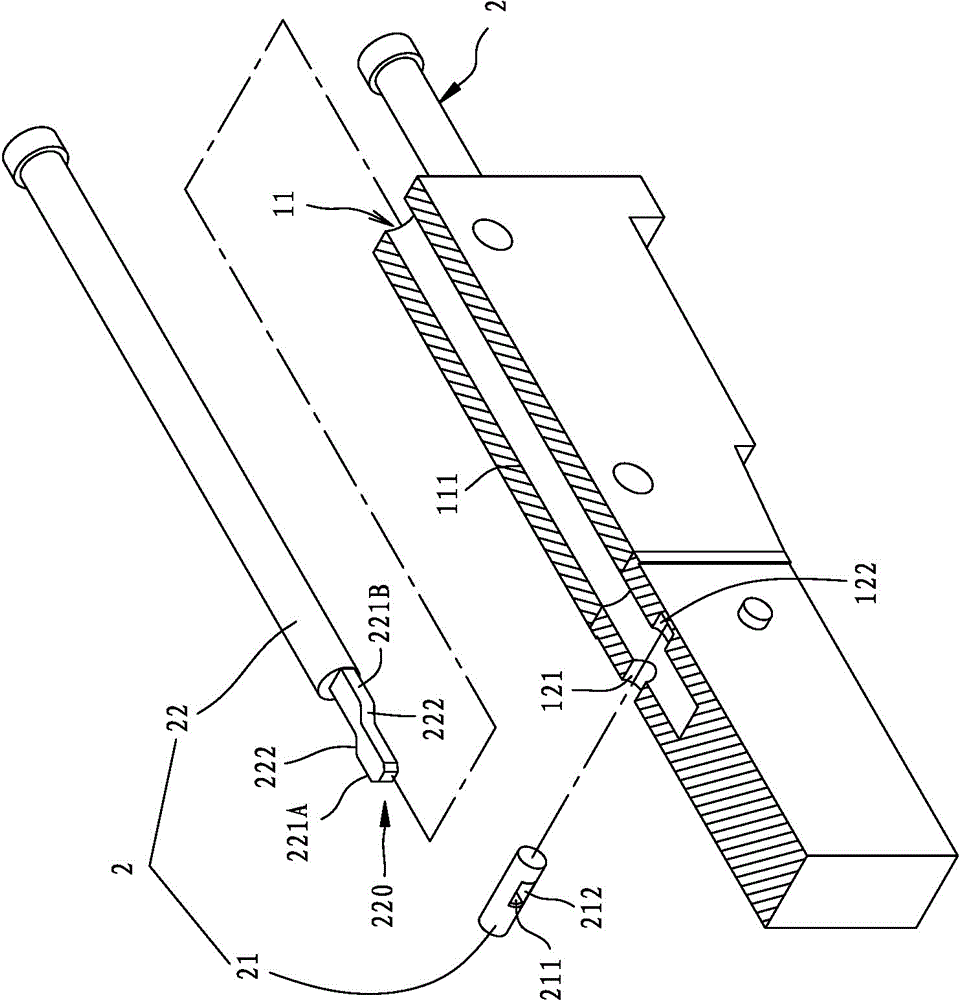

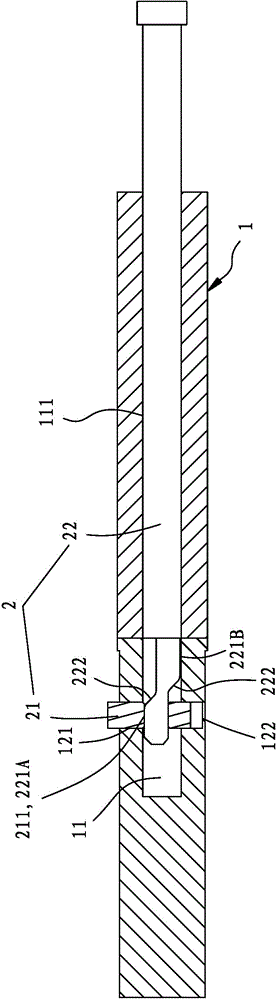

[0070] see first figure 1 and figure 2 , discloses the mold structure with auxiliary molding function in the embodiment of the present invention, including: a mold 1 and a plurality of auxiliary molding components 2, wherein:

[0071] The interior of the mold 1 defines an accommodating space 11, the mold 1 has a molding surface 12, the molding surface 12 is used to form the surface of the object, and the molding surface 12 is provided with an opening 121 to communicate with the accommodating space 11, the mold 1 And a sunken groove 122 is recessed at the place corresponding to the opening 121 . The mold 1 is exemplified as a male mold in this embodiment, but it is not limited thereto, and may also be a female mold, or a single moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com