A crane trolley anti-gnawing rail system

A technology of cranes and trolleys, applied in the directions of traveling mechanism, load hanging components, transportation and packaging, etc., can solve problems such as inconvenient correction, injury to human life, inconvenient analysis, etc., to achieve easy maintenance and maintenance, prevention of accidents, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

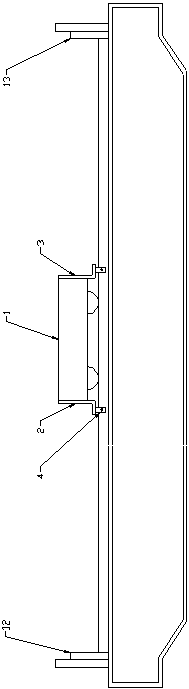

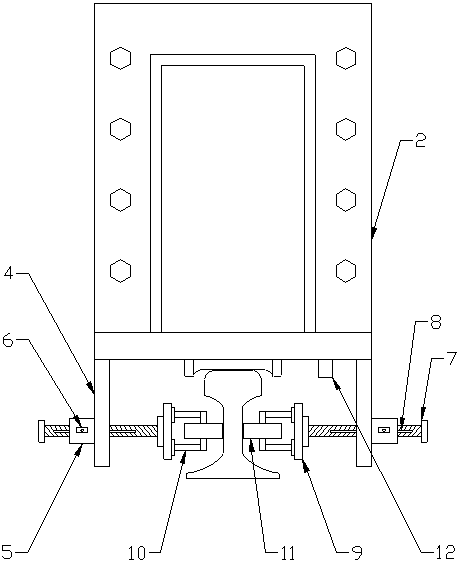

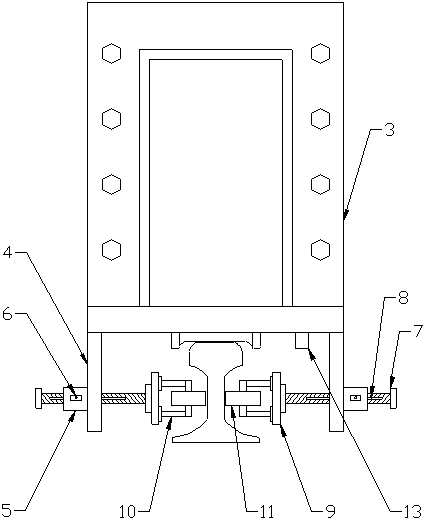

[0015] Such as Figure 1-3 As shown, a crane trolley anti-gnawing rail system, it includes a trolley body 1, the left and right ends of the trolley body 1 are respectively provided with an L-shaped end plate A2 and an end plate B3, the bottom of the end plate A2 A laser emitter A4 is arranged on the right side of the center of the surface, a laser emitter B5 is arranged on the left side of the center of the lower surface of the end plate B3, and mounting plates 4 are arranged at both ends of the lower surface of the end plate A2 and the end plate B3, The center of the outer surface of the mounting plate 4 is provided with an adjustment seat 5, the center of the adjustment seat 5 is provided with a threaded hole penetrating the installation plate, and the side of the adjustment seat 5 is provided with a pin hole passing through the axis. A pin shaft 6 is arranged in the pin hole of the shaft, and an adjusting rod 7 is arranged in the adjusting seat 5. The adjusting rod 7 is pro...

Embodiment 2

[0018] Such as Figure 1-3 As shown, a crane trolley anti-gnawing rail system, it includes a trolley body 1, the left and right ends of the trolley body 1 are respectively provided with an L-shaped end plate A2 and an end plate B3, the bottom of the end plate A2 A laser emitter A4 is arranged on the right side of the center of the surface, a laser emitter B5 is arranged on the left side of the center of the lower surface of the end plate B3, and mounting plates 4 are arranged at both ends of the lower surface of the end plate A2 and the end plate B3, The center of the outer surface of the mounting plate 4 is provided with an adjustment seat 5, the center of the adjustment seat 5 is provided with a threaded hole penetrating the installation plate, and the side of the adjustment seat 5 is provided with a pin hole passing through the axis. A pin shaft 6 is arranged in the pin hole of the shaft, and an adjusting rod 7 is arranged in the adjusting seat 5. The adjusting rod 7 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com