Electric vehicle underground garage center conveying table assembly

A technology of underground garages and conveying platforms, which is applied to buildings, building types, buildings, etc. where cars are parked. It can solve the problems of large force, different gaps, and easy damage of rolling bearings, and achieve the effect of stable and reliable operation and large bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

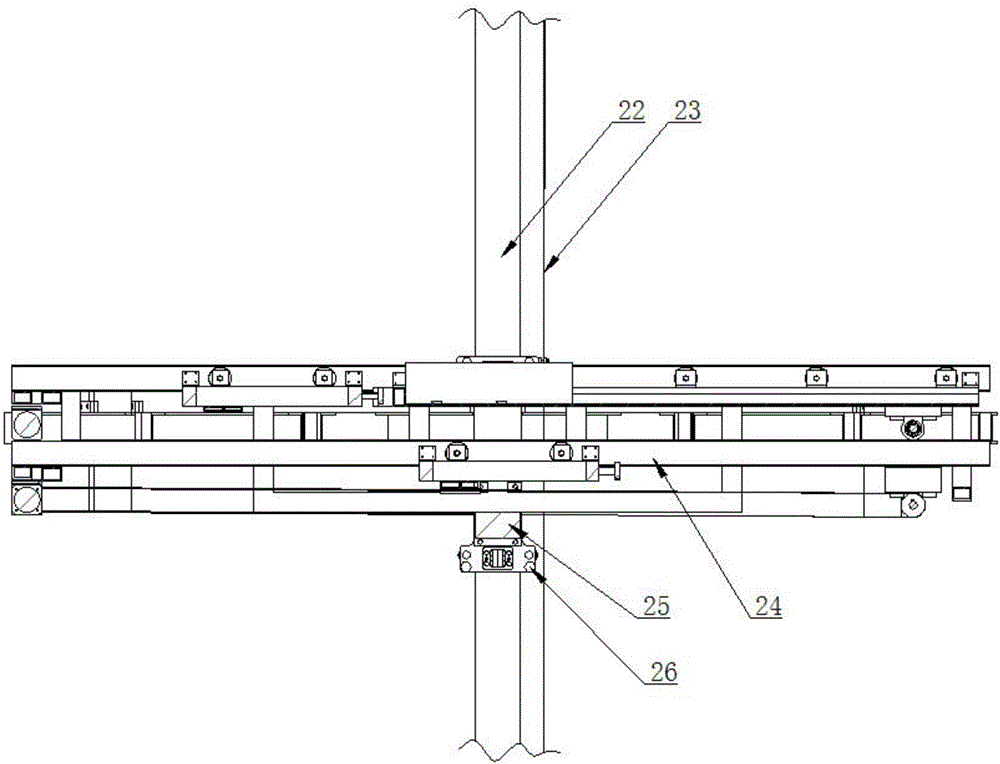

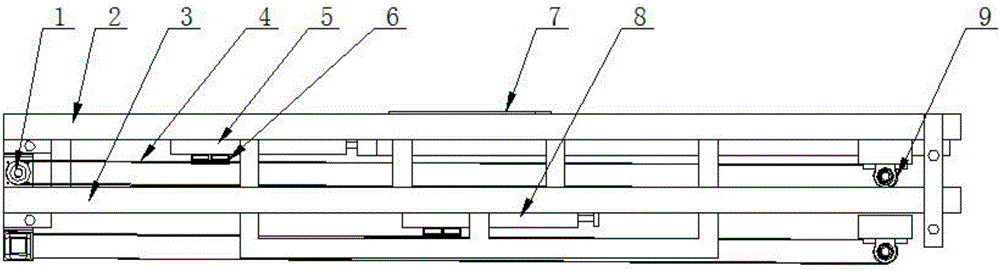

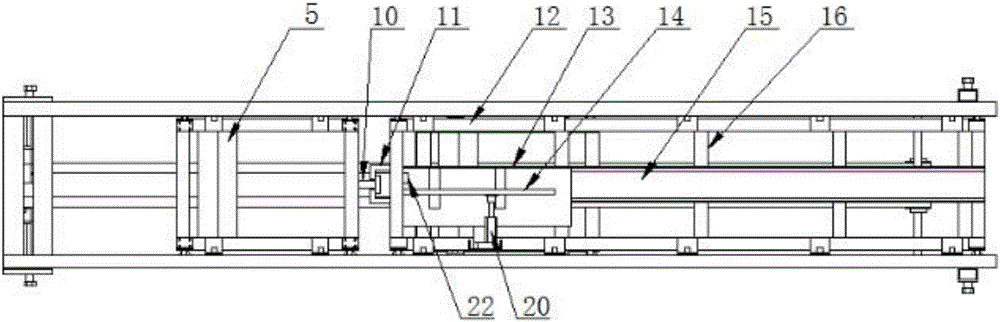

[0041] A central conveyor assembly of an electric vehicle underground garage includes two parallel rotating guide rails 22, and a lifting timing belt 23 is cyclically installed on the rotating guide rails. A conveyor platform driven by a lifting timing belt is set between the rotating rails. The conveyor platform includes a horizontal frame 25, a rail slide 26, and a double-layer vehicle carrying device 24. Both ends of the horizontal frame are provided with rails that guide and run on the rotating rails. The sliding seat is installed horizontally and vertically with a double-layer vehicle carrying device on the horizontal frame. The guide rail sliding seat is fixedly connected with the lifting timing belt. The guide rail sliding seat is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com