Water-injection Cooling System in Supercharged Cylinder of Piston Reciprocating Internal Combustion Engine

A pressurized cylinder, internal combustion engine technology, applied in the direction of internal combustion piston engine, combustion engine, engine cooling, etc., can solve the problems of no buffer, timing, constant speed, cost increase, difficulty in manufacturing, installation and maintenance, etc., to achieve up and down reciprocating motion Stable, accurate and reliable, save the trouble of installation and maintenance, and overcome the effect of poor work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

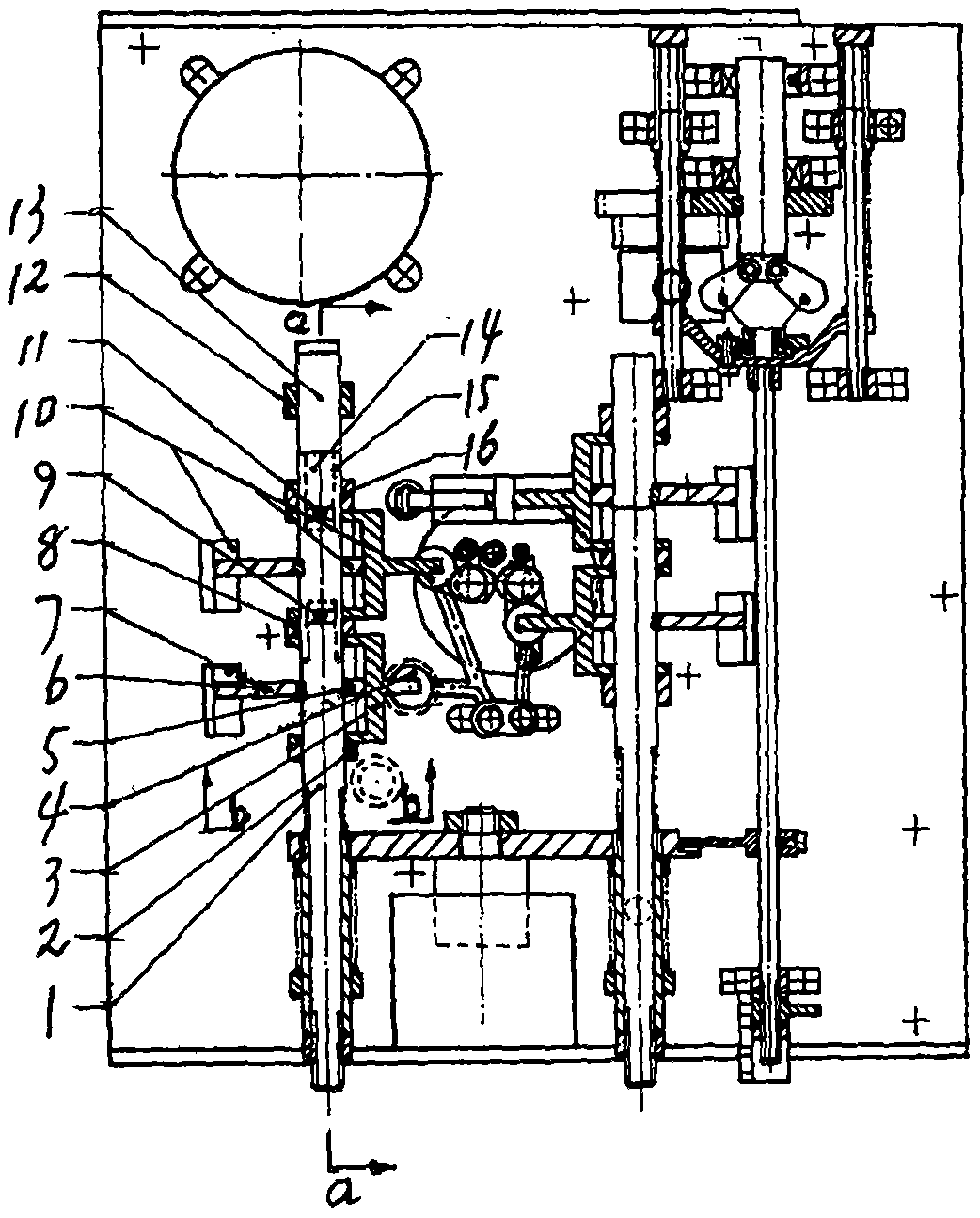

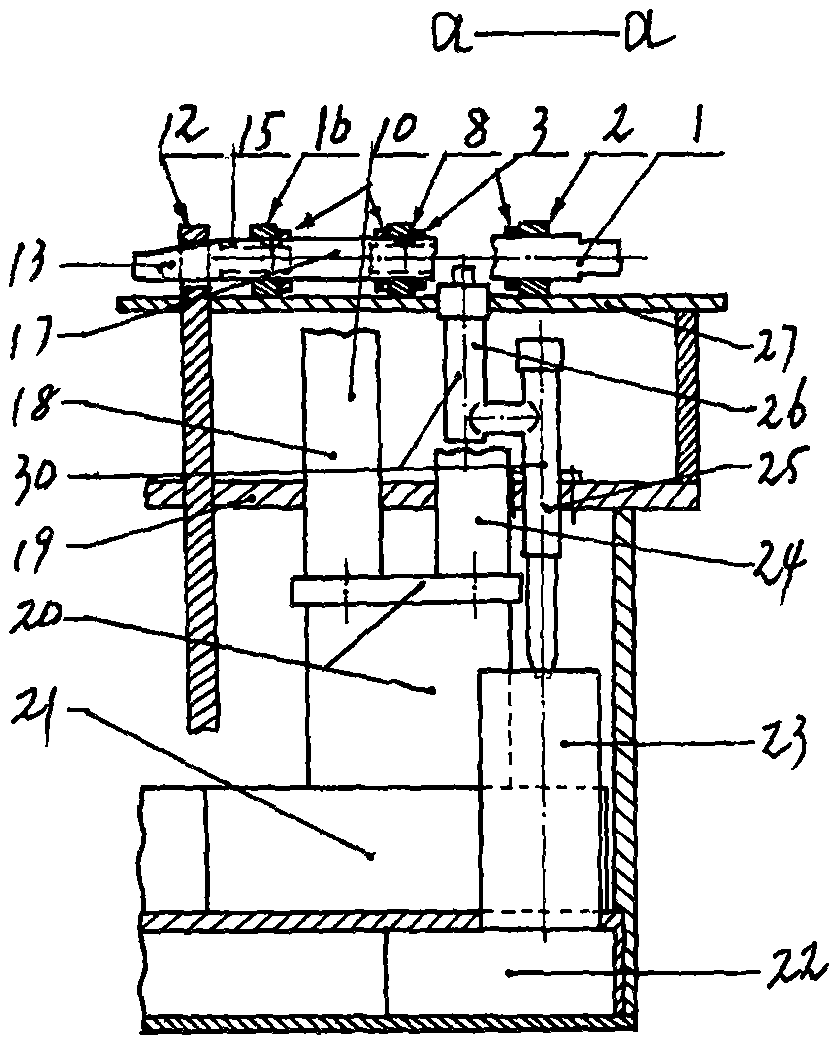

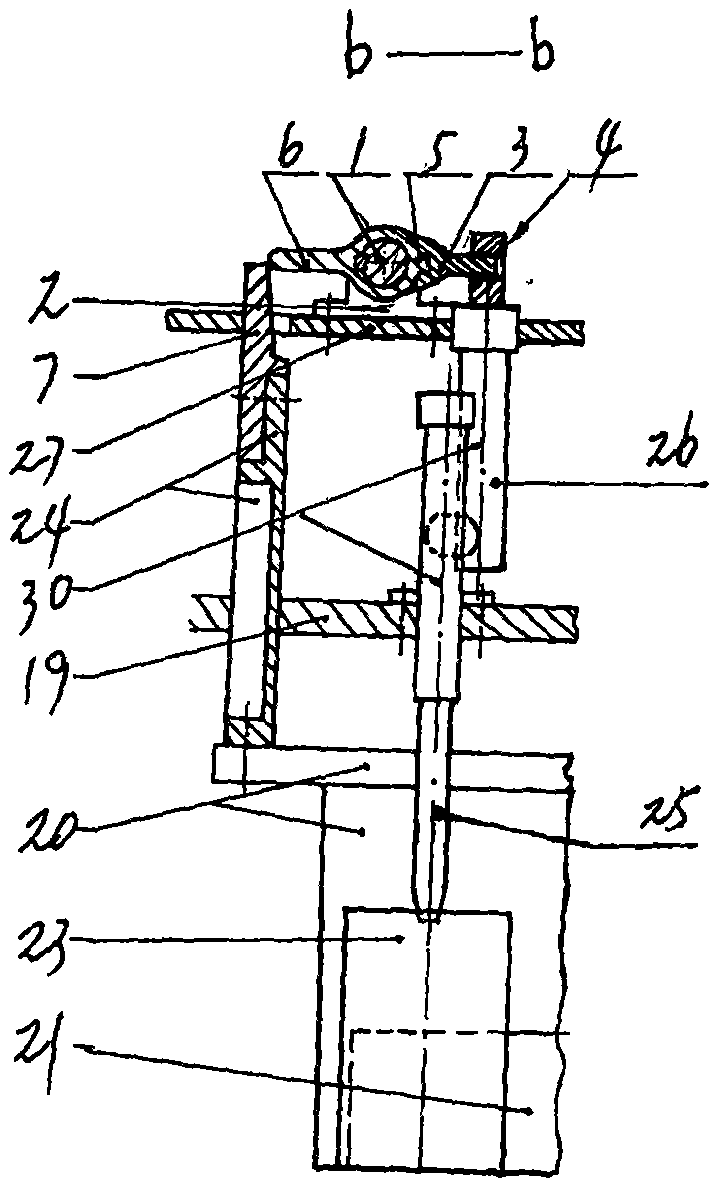

[0017] The specific implementation of the water-cooling system (hereinafter referred to as the "invention system") in the booster cylinder of the present invention is as follows:

[0018] will Figure 4 In the background art, the sliding shaft 42 and the sliding shaft 42 of the "secondary engine cylinder water injection cooling system 10" and the "supercharged cylinder water injection cooling system" (hereinafter referred to as the "background system") move axially with changes in engine operating conditions 46 is combined into a sliding shaft; and the sliding shaft is divided into three sections: shaft section 1, shaft section two 17, and shaft section three 13. These three shaft sections are connected by an axial positioning pin and synchronized with the engine The change of working condition makes axial movement, and makes sliding connection with shaft seat 2, 8, 16 to slide in the shaft hole, such as figure 1 , 2 show.

[0019] Such as figure 1 with 2 Shows: The "secondary engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com