Block brake friction plate warning device

An alarm device and brake technology, applied in the direction of brake type, mechanical equipment, etc., can solve the problems of uncertain location and environment of the equipment, frequent contact of unfavorable personnel, and inability to exert the strength of professional inspections to avoid false alarms and The effect of frequent alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

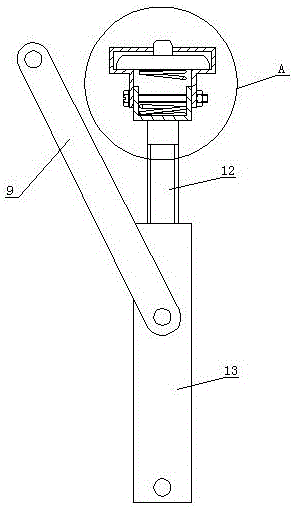

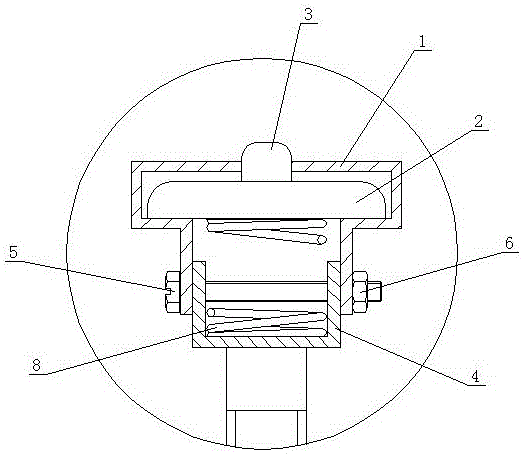

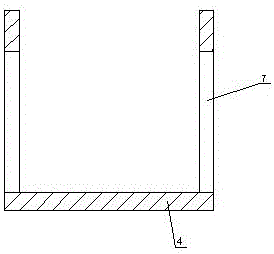

[0035] Such as Figure 1 to Figure 7 As shown, the present invention includes a switch support seat 1, a control switch 2 is arranged in the switch support seat 1, and a button 3 of the control switch protrudes from the top of the switch support seat 1, and two corresponding connecting ports are provided on both sides of the lower part of the switch support seat 1. Bolt holes, the lower part of the switch support base 1 is sleeved on the base 4, and a connecting bolt 5 passes through the two connecting bolt holes on the switch support base 1 and the two side walls of the base 4, and then connects the switch support base 1 and the base 4 through the connecting nut 6. The base 4 is connected, and the bottom of the base 4 is provided with a height adjustment device. The height adjusting device comprises a screw rod 12 , the upper end of the screw rod 12 is fixedly connected with the bottom of the base 4 , and the lower part of the screw rod 12 cooperates with the internal thread ...

Embodiment 2

[0043] Such as Figure 8 ~ Figure 12 As shown, the difference between this embodiment and Embodiment 1 is that the height adjustment device includes an upper frame body 14 and a lower frame body 15, the upper end of the upper frame body 14 is fixedly connected with the bottom of the base 4, and the lower frame body 15 is sleeved on the lower part of the upper frame body 14 , two positioning bolt holes 16 are provided on the corresponding side walls of the lower frame body 15, and a number of adjusting bolt holes 17 matched with the positioning bolt holes 16 are arranged on the upper frame body 14 at intervals along its height direction, and a positioning bolt 18 After passing through the positioning bolt holes 16 and any adjusting bolt holes 17, the upper frame body 14 is connected with the lower frame body 15 through a positioning nut 19 . The bottom of the control switch 2 in the switch support seat 1 is provided with an adjusting gasket (not shown in the figure).

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com