Safety double solenoid valve

A solenoid valve, pilot solenoid valve technology, applied in valve details, valve devices, multi-port valves, etc., can solve the problems of unreliable action, pilot control air source interference, large action time dispersion, etc., to improve asynchronous commutation. performance, improve cross-checking performance, weaken the effect of orifice effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings.

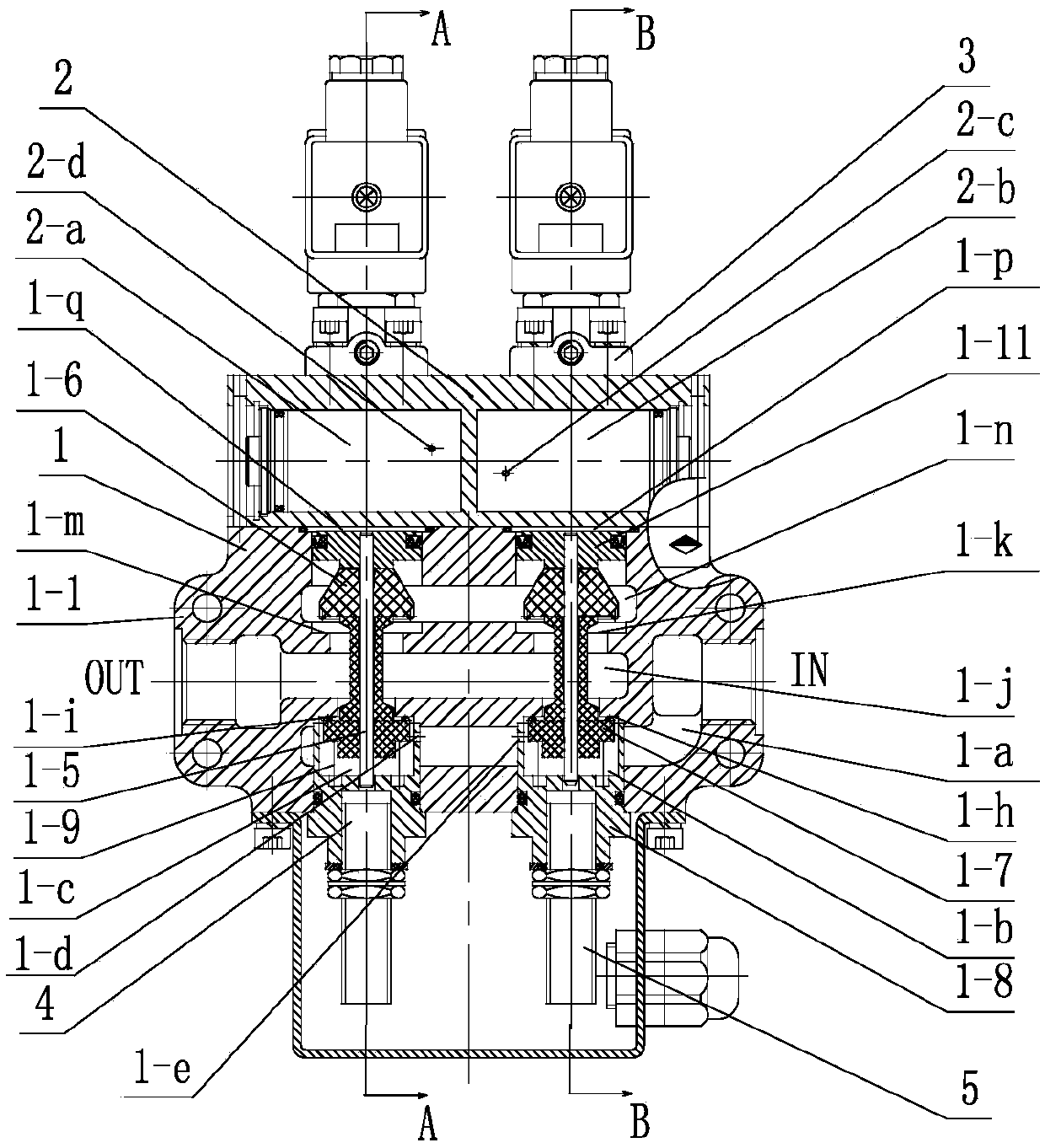

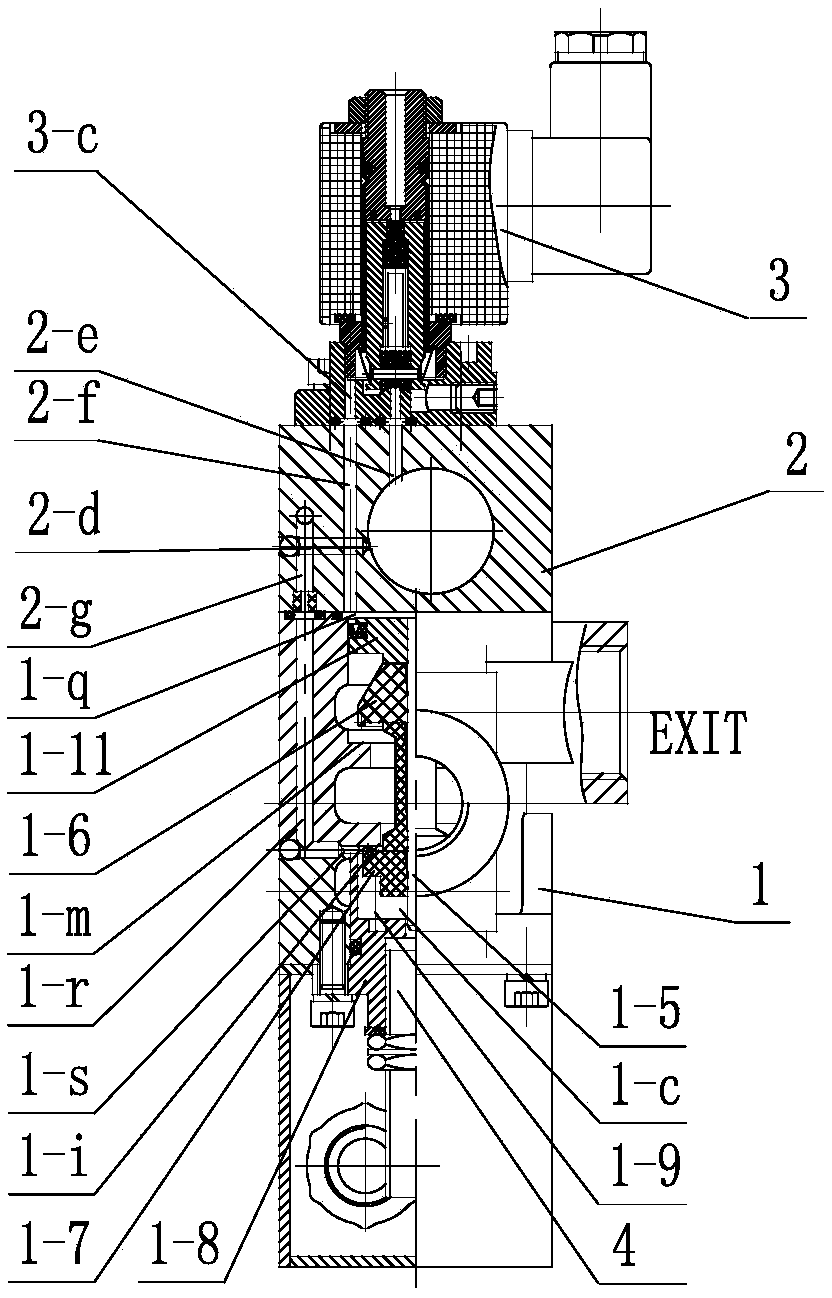

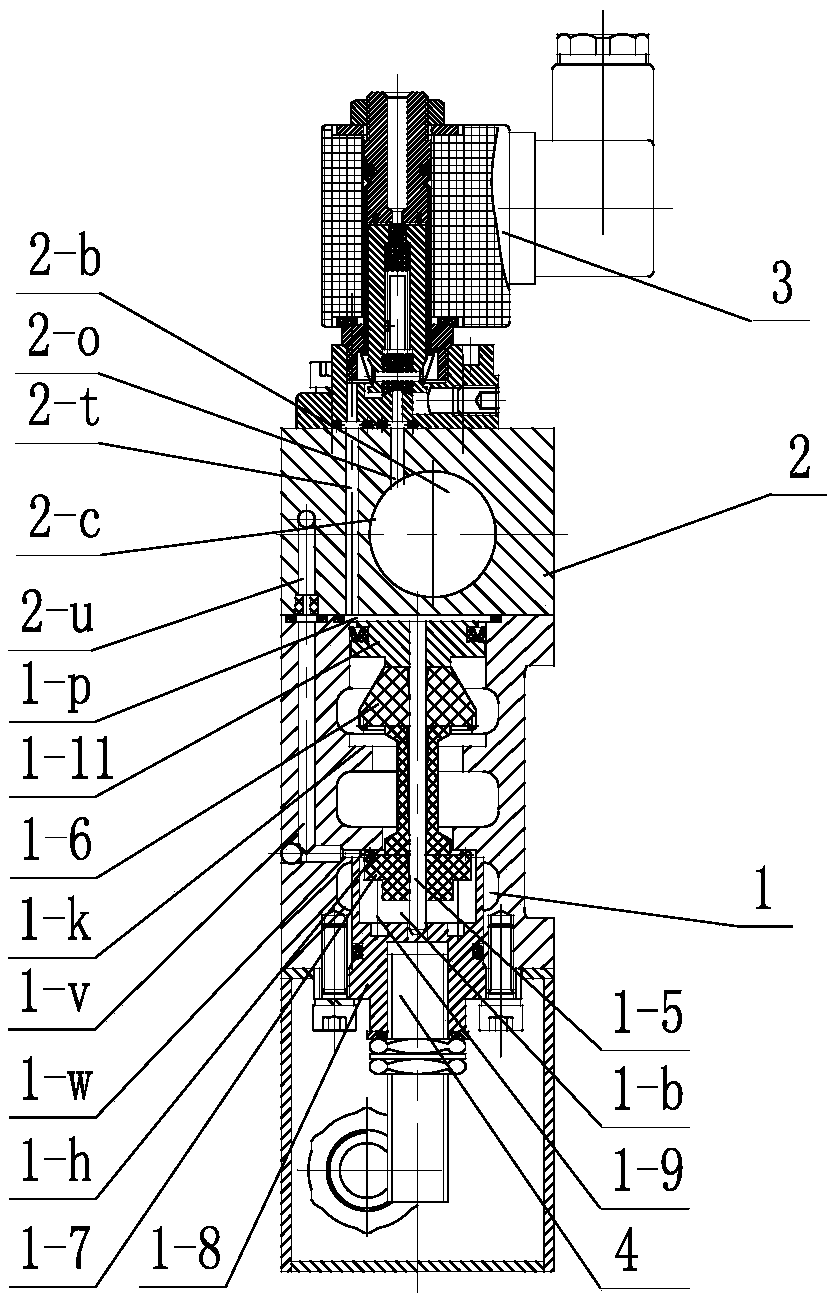

[0026] Such as Figure 1 to Figure 10 As shown: the safety double solenoid valve includes a main valve assembly 1, a pilot valve seat 2, a pilot solenoid valve 3, a first proximity switch 4, a second proximity switch 5, an air inlet IN, an air outlet OUT, and an exhaust port EXIT, main valve body 1-1, main valve spool 1-5, upper sealing plug 1-6, lower sealing plug 1-7, lower end cover 1-8, main valve return spring 1-9, air intake chamber 1- a. Right single-valve intake cavity 1-b, left single-valve intake cavity 1-c, left single-valve intake orifice 1-d, right single-valve intake orifice 1-e, Left single valve intake valve port 1-i, right single valve intake valve port 1-h, output cavity 1-j, right single valve exhaust valve port 1-k, left single valve exhaust valve 1 -m, exhaust cavity 1-n, right single-valve spool control chamber 1-p, left single-valve spool control chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com