Blade with built-in bed frame-type pneumatic damping device

A technology of pneumatic damping and skeleton row, which is applied to components of pumping devices for elastic fluids, non-variable pumps, jet propulsion devices, etc., to achieve the effects of suppressing vibration, improving impact resistance, and increasing local energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings.

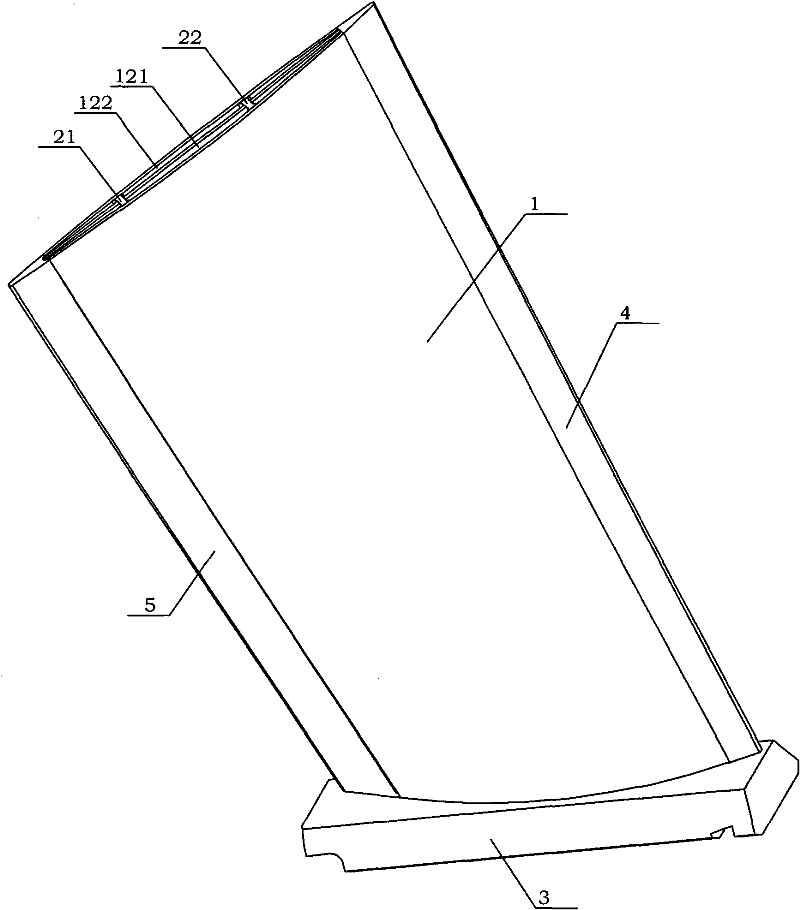

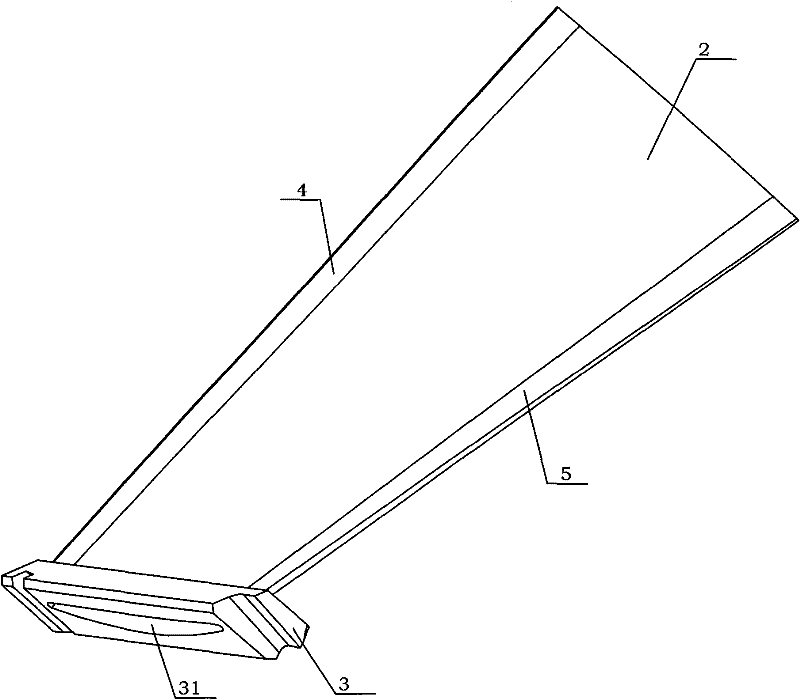

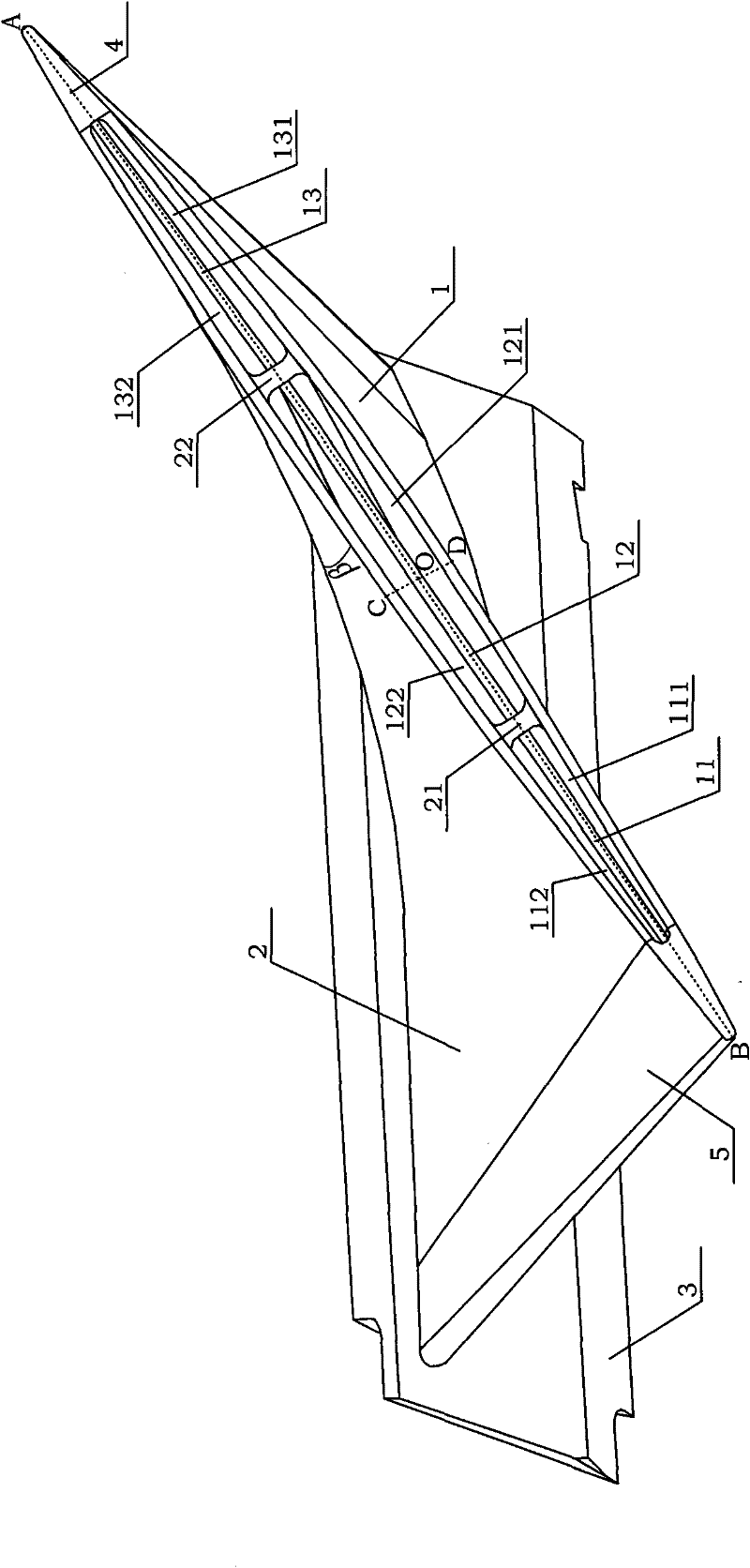

[0038] see figure 1 , Figure 1A , Figure 1B and Figure 1C As shown, a blade with a built-in row frame type aerodynamic damping of the present invention is composed of a blade body and a tenon 3, wherein the blade body includes a blade back side wall 1, a blade pot side wall 2, a leading edge 4, and a trailing edge 5 , A vibration-absorbing plate 11, B vibration-absorbing plate 12, C vibration-absorbing plate 13, A support rib 21 and B support rib 22.

[0039] exist Figure 1B Among them, point A is the center point of the arc-shaped end at the upper end of the leading edge 4, and point B is the center point of the arc-shaped end at the upper end of the trailing edge 5. The line connecting point A and point B is called the line AB, and the line AB is just The midchord line of the blade of the present invention; point C is the center point of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com