Three-rocker type wall switch

A wall switch and rocker technology, which is applied to the parts of the flip switch/rocker switch, etc., can solve the problems of damage to the electrical circuit of the switch component, water leakage from the wall and the floor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

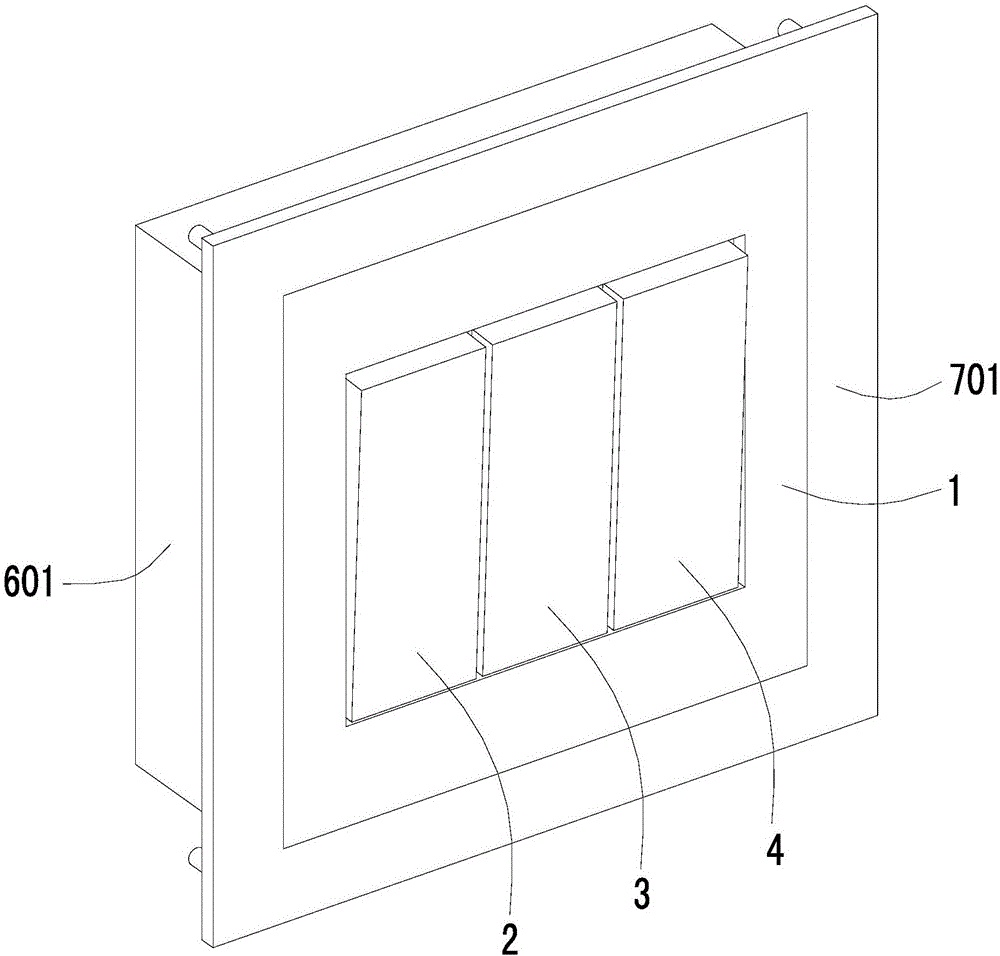

[0059] A three rocker type wall switch, comprising a panel 1 for fixing to the wall, a first group of switch components, a second group of switch components and a third group of switch components, the first group of switch components, the second group of switch components Both the group switch assembly and the third group switch assembly are installed on the panel 1, and the panel is provided with an opening 101, and the first group switch assembly includes a first seesaw 2 for controlling the opening and closing action of the first group switch assembly , the second set of switch assemblies includes a second seesaw 3 for controlling the opening and closing actions of the second set of switch assemblies, and the third set of switch assemblies includes a second rocker 3 for controlling the opening and closing actions of the third set of switch assemblies The third seesaw 4, the first seesaw 2, the second seesaw 3 and the third seesaw 4 are all exposed outside the panel through t...

Embodiment 2

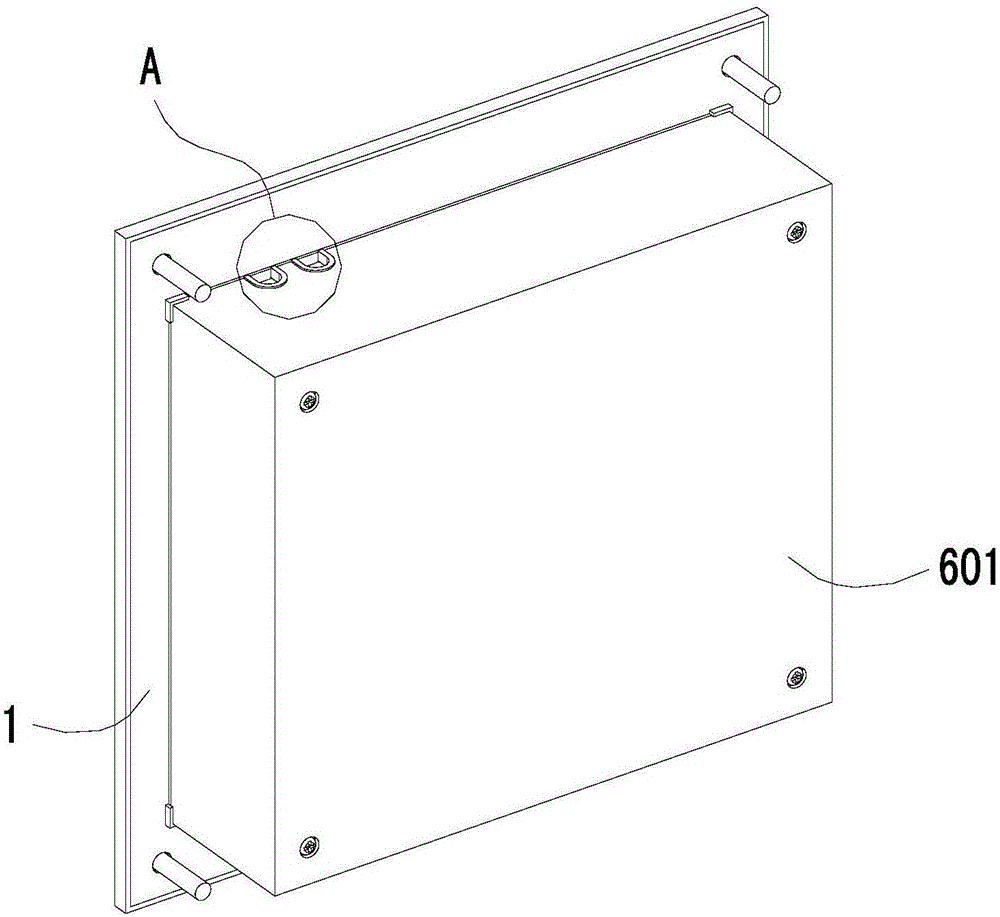

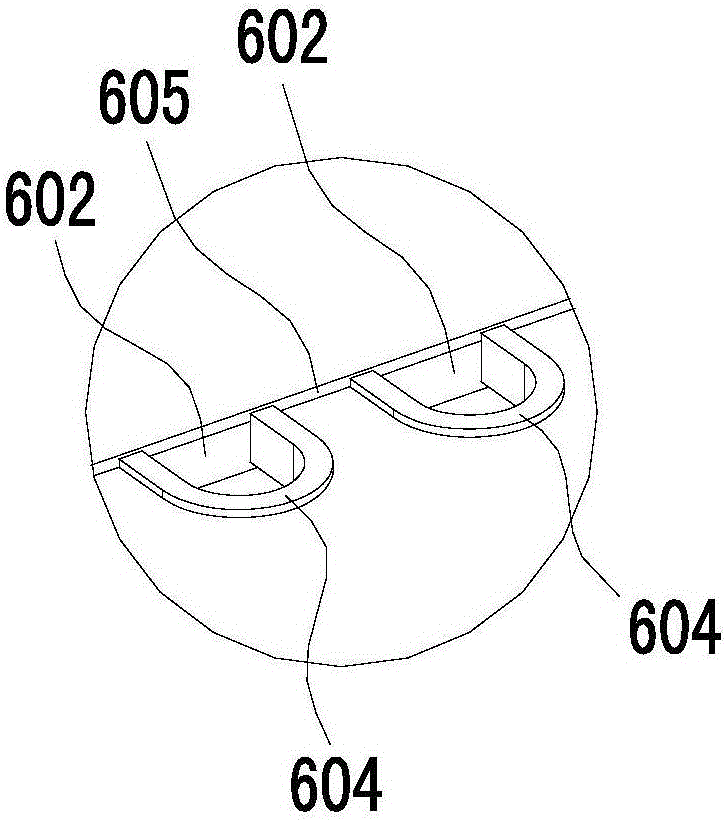

[0067] A three-rocker wall switch that is easy to disassemble. This embodiment is a further limitation made on the basis of Embodiment 1. This embodiment includes all the structural features of Embodiment 1, and makes the following limitations:

[0068] The first pressure frame 6 is detachably locked on the first seesaw 2 through the first screw 60, the second pressure frame 7 is detachably locked on the second seesaw 3 through the second screw 70, and the third The pressure frame 8 is detachably locked on the third rocker 4 through the third screw 80, and the fourth pressure frame 9 is detachably locked on the panel 1 through the fourth screw 90, especially the fourth pressure frame 9 It is detachably locked on the back side 13 of the panel by a fourth screw 90 .

Embodiment 3

[0070] A three-saw type wall switch with double seals, this embodiment is further limited on the basis of embodiment 1 or embodiment 2, and this embodiment includes all the structural features of embodiment 1 or embodiment 2 , and make the following restrictions:

[0071] It also includes a deformable second seal 20 after being stressed. The second seal 20 is in the shape of a square ring and includes a first sealing edge 201, a second sealing edge 202, and a third sealing edge connected end to end in sequence. 203 and the fourth sealing edge portion 204, the opposite edge of the first sealing edge portion 201 is the third sealing edge portion 203, and the opposite edge of the second sealing edge portion 202 is the fourth sealing edge portion 204;

[0072] The fourth press frame 9 is in the shape of a square ring, comprising a first side portion 91 of the fourth press frame connected end to end, a second side portion 92 of the fourth press frame, a third side portion 93 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com