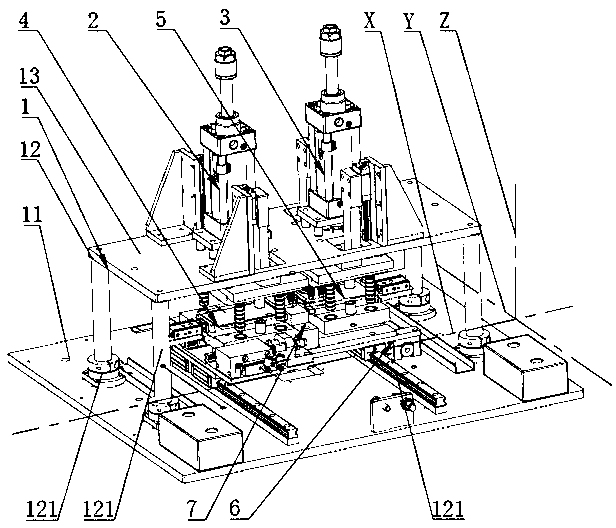

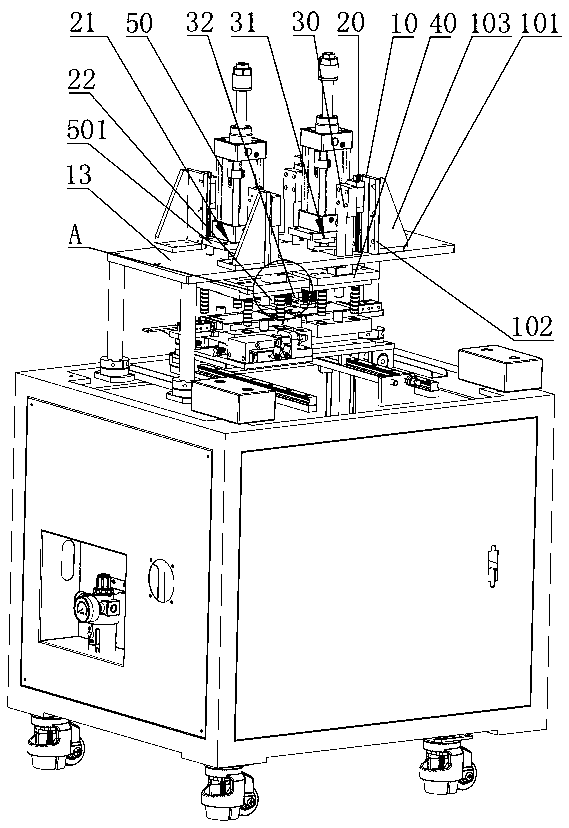

Light guide plate pouring gate cold-cutting machine for cutting step by step and cold-cutting method thereof

A light guide plate and gate technology, which is applied to the step-by-step cutting light guide plate gate cold cutting machine and its cold cutting field, can solve the problems of unguaranteed quality, increased enterprise cost, and high labor intensity, and reduce damage to the guide rail plate The possibility of improving processing efficiency and ensuring the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

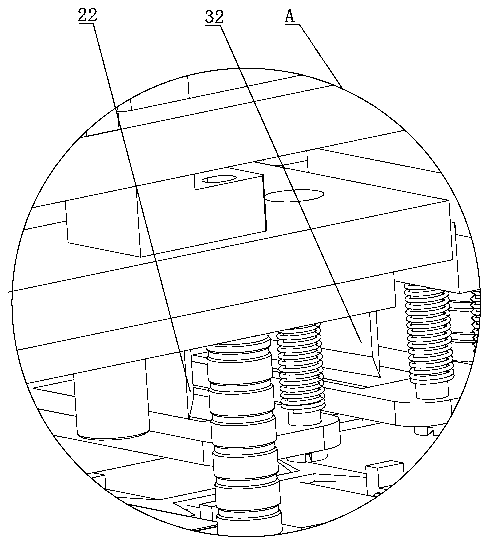

[0072] The overall structure of this embodiment is similar to that of Embodiment 1, and the difference is that: the bearing plates 41 of the first vacuum positioning jig 4 and the second vacuum positioning jig 5 are respectively provided with limiting holes 411, and the installation The bottom of the plate 40 is respectively provided with positioning posts 60 matching the limiting holes 411, and the number of the limiting holes 411 and the positioning posts 60 are four respectively.

[0073] The overall process of this embodiment is similar to that of Embodiment 1, the difference is that when the driving cylinder 50 pushes the mounting plate 40 down, the positioning column 60 moves down at the same time, and is inserted into the bearing The positioning hole 411 on the plate 41 ensures accurate positioning of the first cutting device 2 and the first vacuum positioning jig 4 as well as the second cutting device 3 and the second vacuum positioning jig 5 .

Embodiment 1

[0075] The overall mechanism of embodiment 1 is similar to that of embodiments 1 and 2, and the difference is that: the bottoms of the two mounting plates 40 are respectively equipped with lower pressing plates 70, and one edge of the two lower pressing plates 70 is respectively connected to the first The cutting point positions of the cutting knife 22 and the second cutting knife 32 on the workpiece 8 correspond, and the main bodies of the two lower pressing plates 70 are respectively pressed on the first vacuum positioning jig 4 and the second vacuum positioning jig 4 and the second vacuum positioning jig 4 . Position the molded part in jig 5.

[0076] The lower pressing plate 70 is provided with at least three through holes, and a sliding bar 80 is inserted in the three through holes, and the lower pressing plate 70 can slide up and down along the sliding bar 80, and the sliding bar 80 The jacket is provided with a spring 90 , the upper end of the spring 90 is affixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com