Novel liquid soap pump

A soap liquid, a new type of technology, applied in home appliances, sanitary equipment, applications, etc., can solve the problems of glass balls being easily stuck on the spring, soap liquid pump damage, etc., and achieve the effect of simple and reliable structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

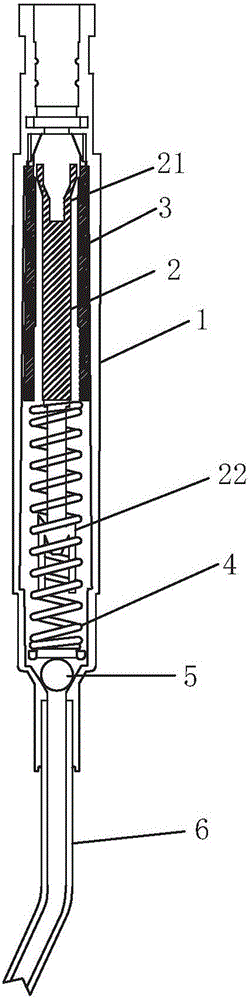

[0009] refer to figure 1 , a new type of soap liquid pump of the present invention, comprising a body 1 and a main column 2 installed in the body 1, a piston sleeve 3, a spring 4, and a glass ball 5, the bottom end of the body 1 is connected with a suction pipe 6, the The piston sleeve 3 is set on the outside of the main column 2 and can move up and down along the inner wall of the main body 1. The lower part of the main body 1 is provided with a constriction port for supporting the glass ball 5, and the glass ball 5 is located on the constriction port. An elastic bayonet 21 stuck in the piston sleeve 3 is provided, and the lower part of the main column 2 is provided with an outer expansion part 22 for fixing the spring 4 , and the outer expansion part 22 is suspended above the glass bulb 6 .

[0010] The inner wall of the piston sleeve 3 is provided with a protrusion that cooperates with the elastic bayonet 21 of the main column 2 .

[0011] In the novel soap liquid pump of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com