A method for removing hemp from hemp

A technology for removing hemp and hemp, which is applied in the field of machinery and equipment for primary processing of hemp fibers, can solve the problems of low quality of direct-feeding processing, immature mechanized processing equipment and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described further below:

[0025] In the present invention, the orientation words used such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" refer to the outline relative to each part itself inside and outside.

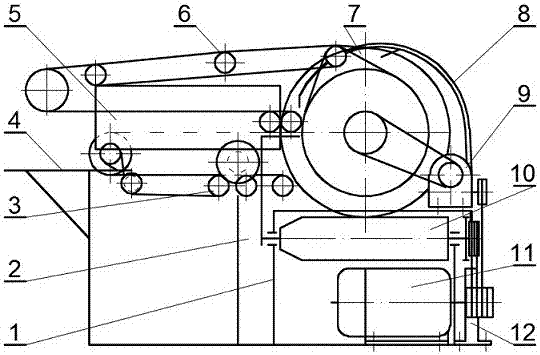

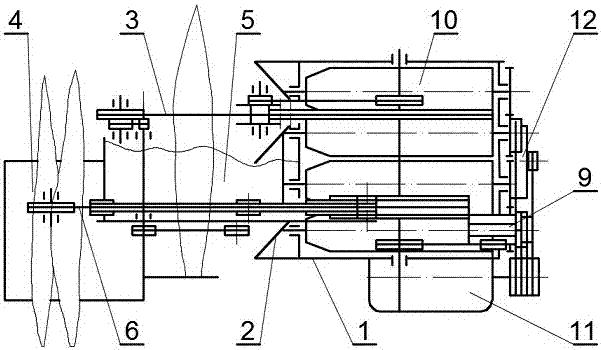

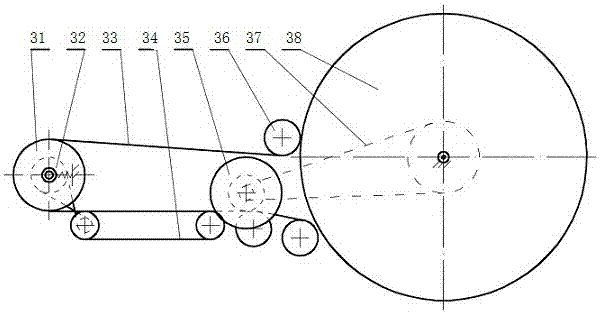

[0026] see figure 1 , figure 2 , image 3 , the whole machine is divided into frame 1, feeding port 2, hemp stalk (hemp leaf) clamping and conveying device 3, hemp stalk (hemp leaf) stacking platform 4, fiber collecting tank 5, fiber clamping and conveying device 6, coupling ring 7. Blowing pipe 8 and mouthpiece, worm gear reducer 9, denumbing device 10, motor 11, powerful blower 12 and other parts; two sets of denumbing devices 10 have two pairs of denumbing rollers arranged in parallel horizontally, and the two sets of denumbing devices are clamped and conveyed The clamping driving wheel of the device is coaxially installed directly above the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com