Inclined partition wall structure with ALC autoclaved aerated concrete battens and construction method

An autoclaved air-filling and concrete technology, which is applied to walls, building components, building structures, etc., can solve problems such as high construction cost, long construction period, and complicated construction procedures, and achieve simple construction quality control, reduce construction costs, and speed up construction. The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

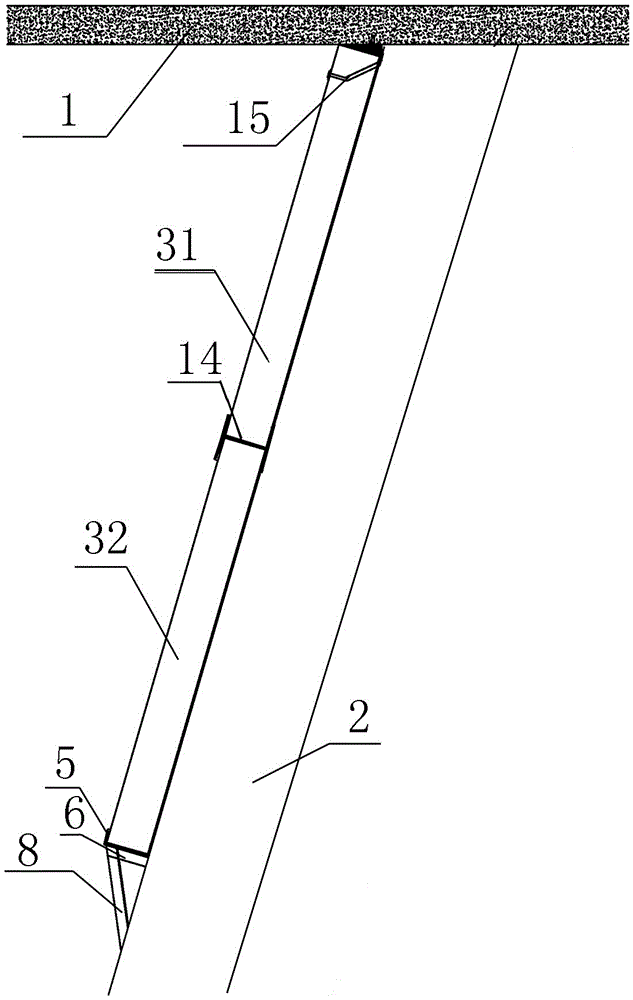

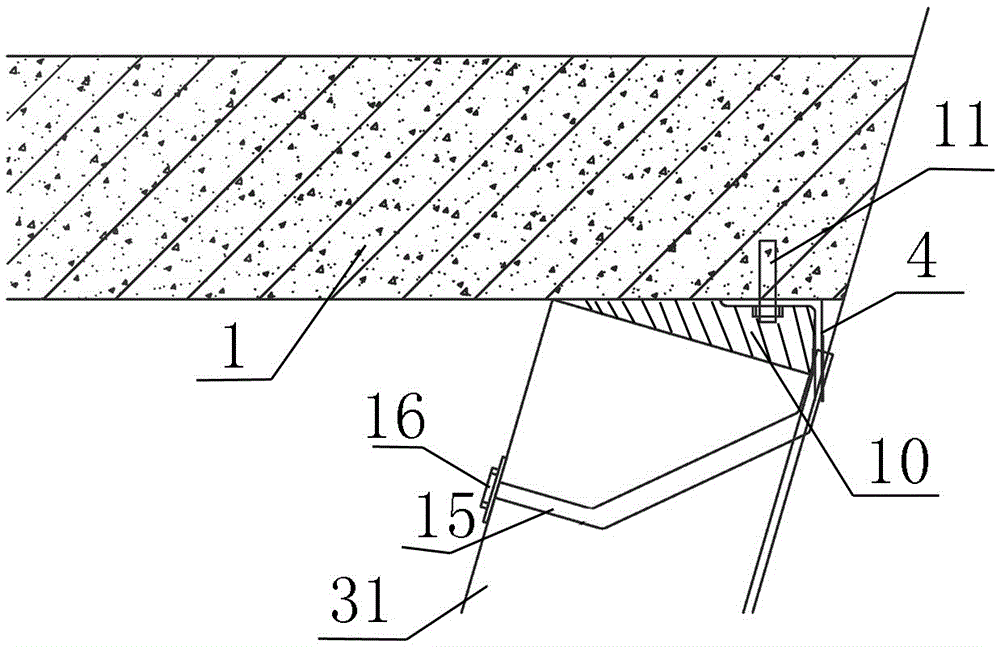

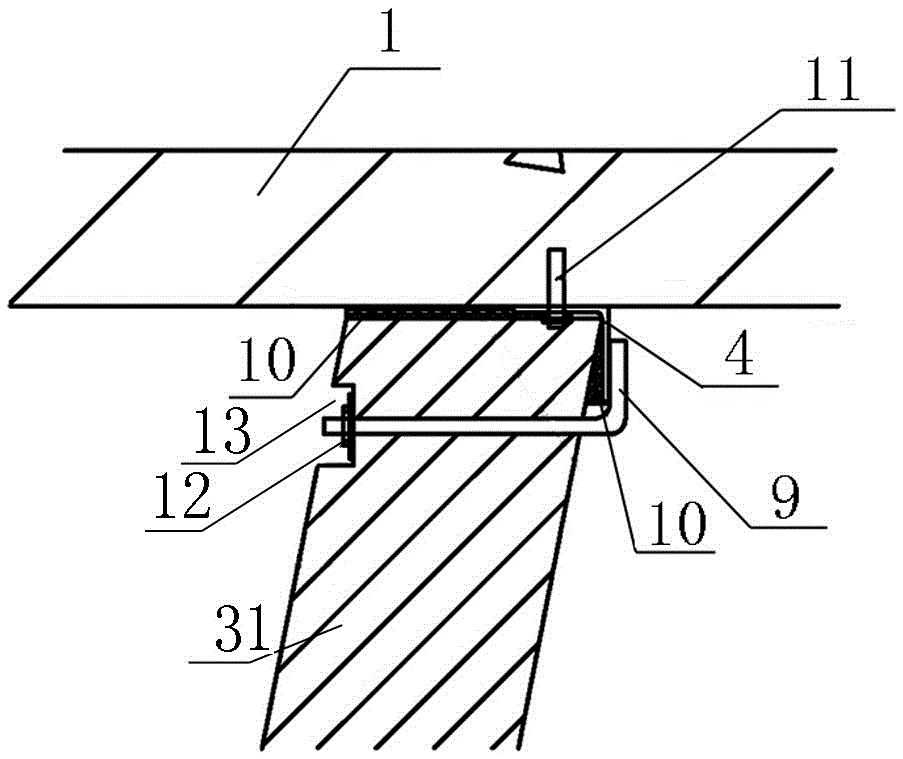

[0040] In this embodiment, the ALC autoclaved aerated concrete strip partition wall is used as the outer wall and installed on the outer edge of each floor. First, fix hot-dip galvanized angle steel at the position of the superstructure 1 (roof beam) and the substructure 2 (steel structure column) according to the inclination angle of the drawing, as the top keel 4 and bottom keel 5 of the ALC autoclaved aerated concrete slab. The ALC autoclaved aerated concrete slab is fixedly installed with the top keel 4 and the bottom keel 5 respectively by using connectors, and the connectors are fully welded with the top keel 4 angle steel. A vertical I-shaped steel keel 7 is added to the splicing position of two ALC autoclaved aerated concrete slabs, and two adjacent ALC autoclaved aerated concrete slabs are connected by a vertical I-shaped steel keel 7 to ensure that the ALC autoclaved aerated concrete strip board integrity. The gaps between the slabs, the ALC autoclaved aerated concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com