Segmented installation method of large mirror door

An installation method and large-scale technology, applied in coastline protection, water conservancy engineering, marine engineering and other directions, can solve the problems of inability to carry out transportation and lifting, difficult to eliminate accumulated errors, difficult to locate reference points, etc. The effect of accumulating errors and reducing the difficulty of transportation and hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

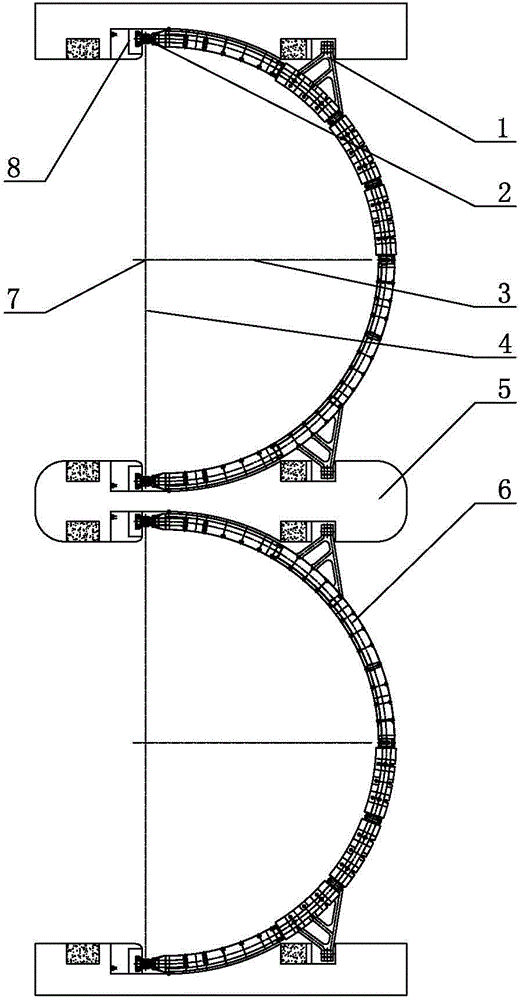

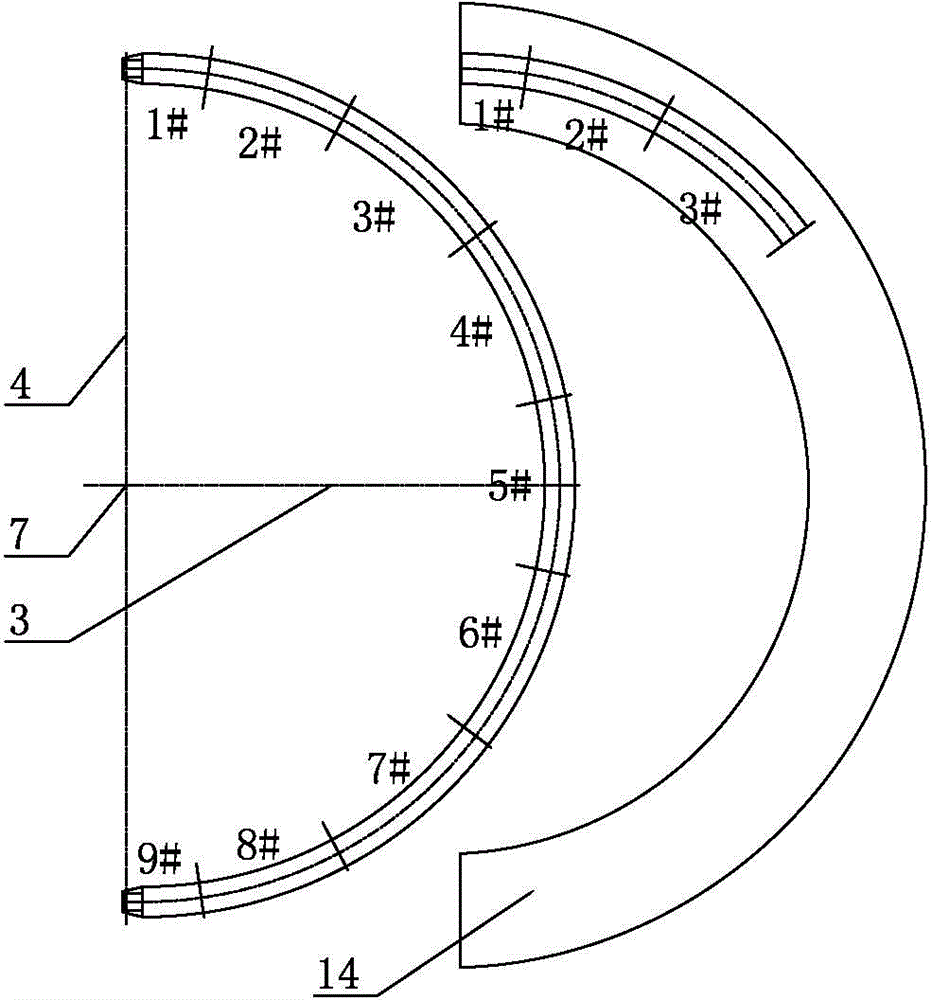

[0026] Such as figure 1 As shown, the mirror door is a double-hole mirror door, with two curved doors 6, the span of each curved door is 44m, and each curved door is divided into 9 sections for manufacture. During its manufacture and installation, press Follow the steps below:

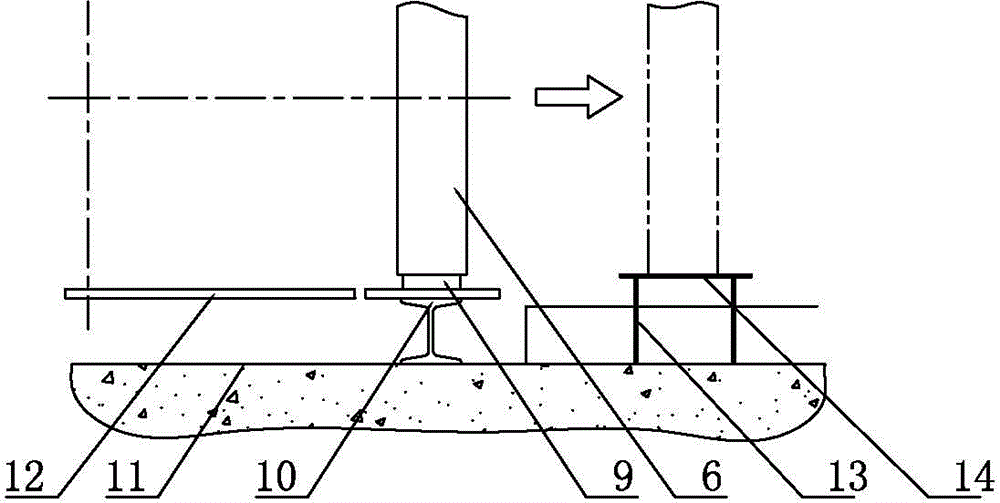

[0027] 1) Carry out concrete foundation construction in the river channel, pour buttresses, hoist mounting seats, river channel floor 11 and stilling piers, determine the installation positions of hoist, sill 10 and hinge seats, and embed them for hoist installation The built-in parts of the machine, the bottom sill 10 and the hinge seat 2; the buttress includes two side piers 8 and a middle pier 5;

[0028] 2) Fix the bottom sill 10 with the embedded parts, adjust the bottom sill 10 to be in a horizontal state; lay a lofting platform 12 on the inner arc side of the bottom sill 10, and the height of the lofting platform 12 is flush with the upper surface of the bottom sill 10; On the platform 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com