PE (Poly Ethylene) fixing plate for capillary network grid

A fixed plate and capillary technology, applied in the field of capillary grid PE fixed plate, can solve the problems of many hidden dangers, high cost, difficult installation and construction of capillary grid, etc., and achieves convenient and simple installation, reasonable structure and simplified construction scheme. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings of the specification, elements having similar structures or functions will be denoted by the same element symbols. The drawings are only for the convenience of illustrating various embodiments of the present invention, and are not intended to describe the present invention exhaustively, nor limit the scope of the present invention.

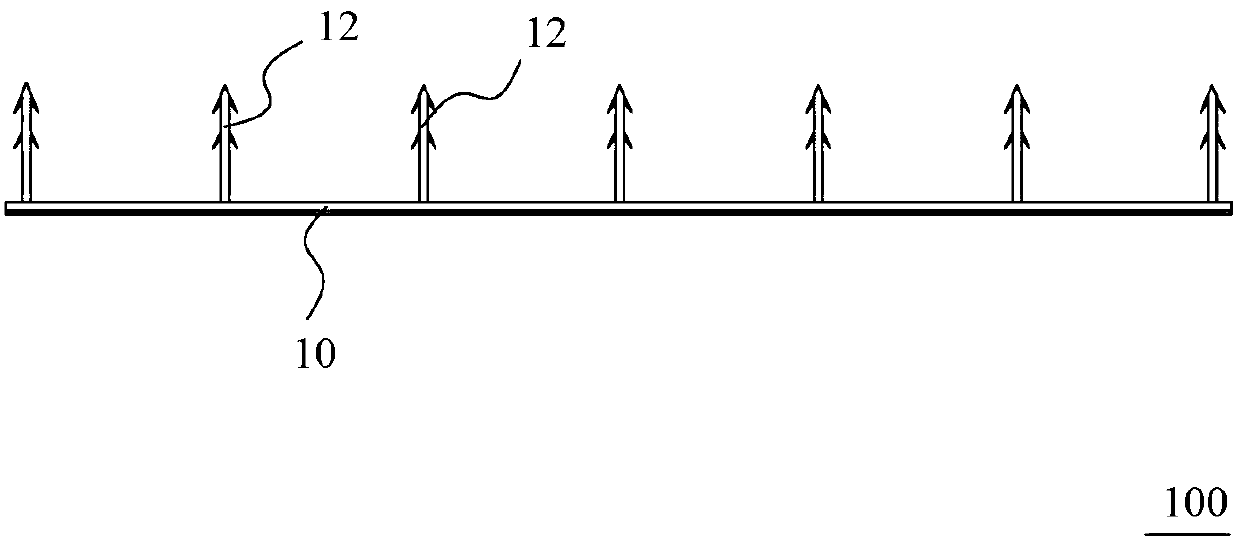

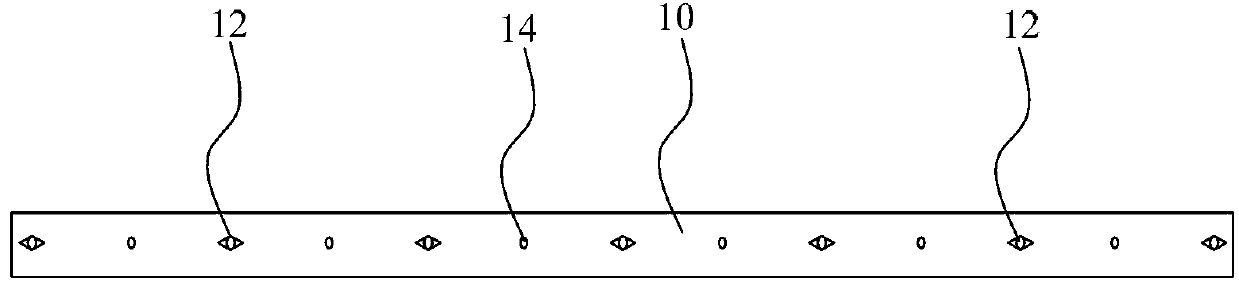

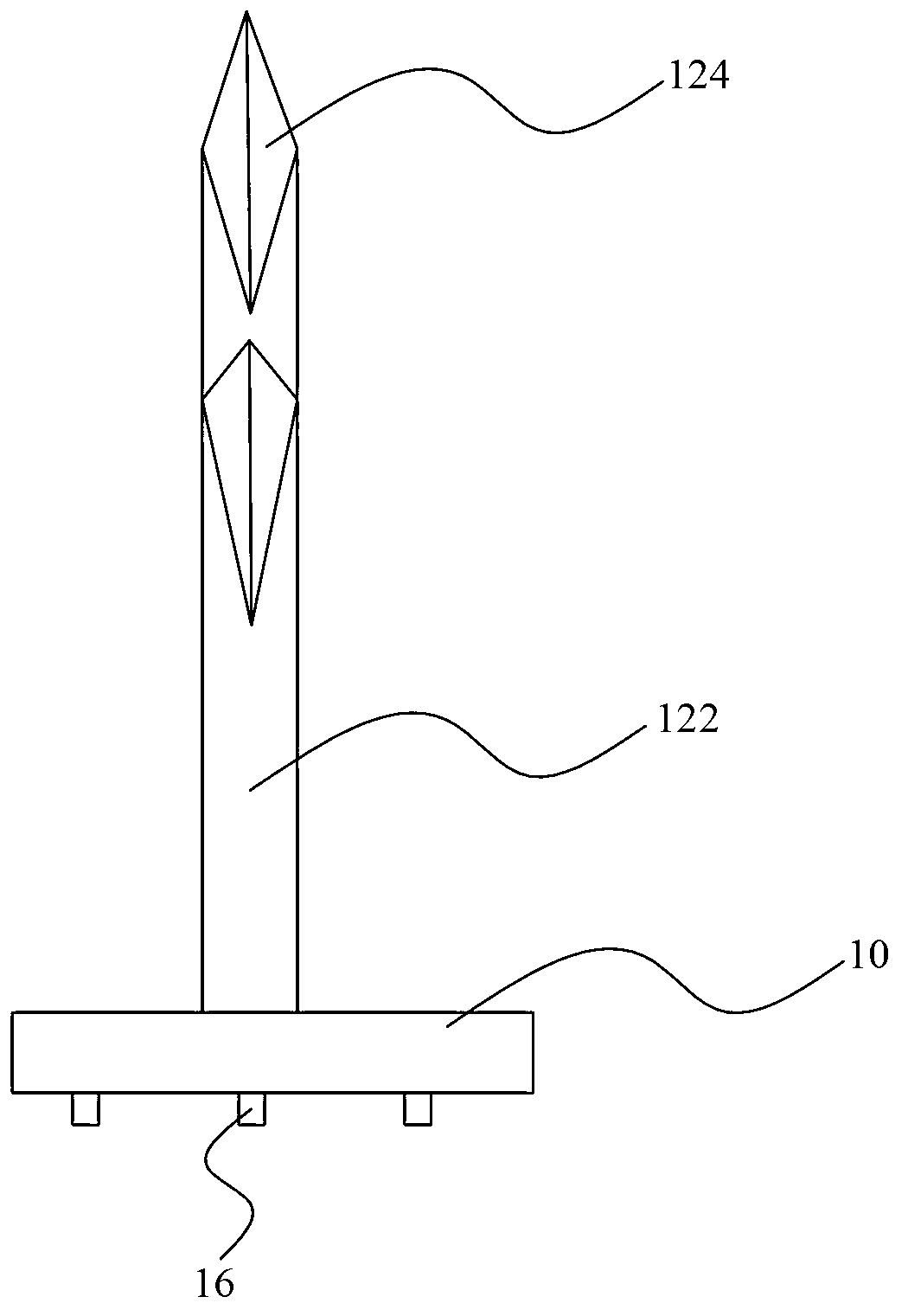

[0021] Figure 1 to Figure 3 A schematic structural view of a capillary grid PE fixing plate according to a specific embodiment of the present invention is shown. In this embodiment, the capillary grid PE fixing plate 100 includes a base plate 10 , fixing pins 12 and reinforcing ribs 16 arranged in parallel on the base plate. The substrate is provided with six through holes 14, each of which has a diameter of 3 mm.

[0022] In a preferred embodiment, the rectangular substrate 10 is made of PE plastic, with a length of 260 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com