Constant flow valve capable of automatically regulating oil fluid delivery flow

An automatic adjustment and constant flow valve technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problems of not being widely used and high cost, and achieve the effect of reducing the range of change and increasing the opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

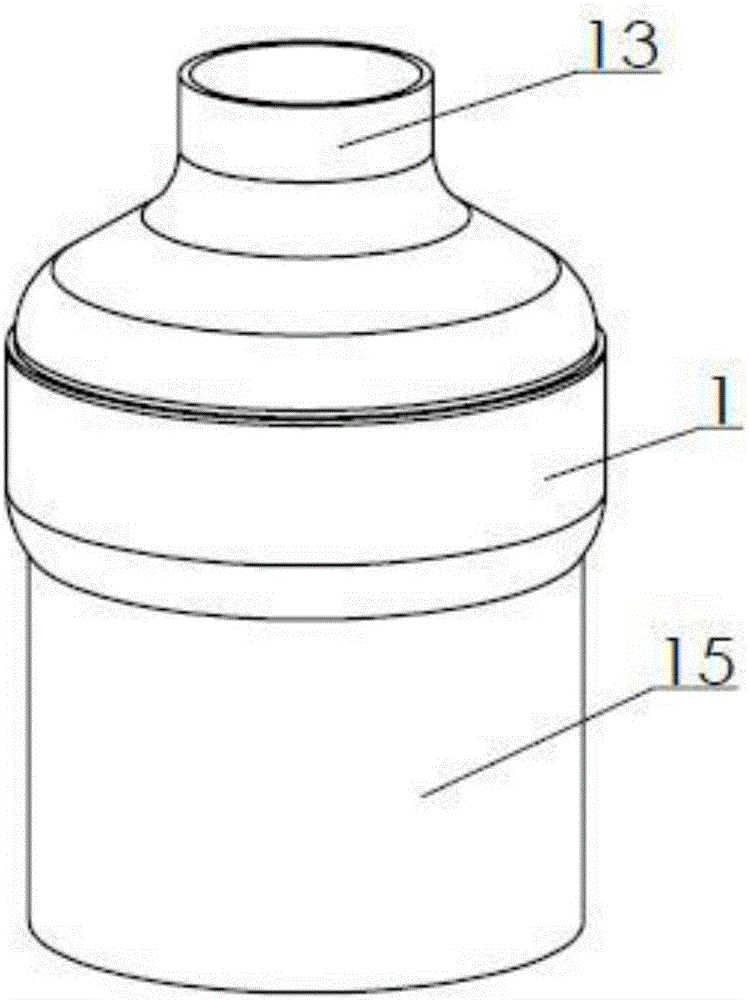

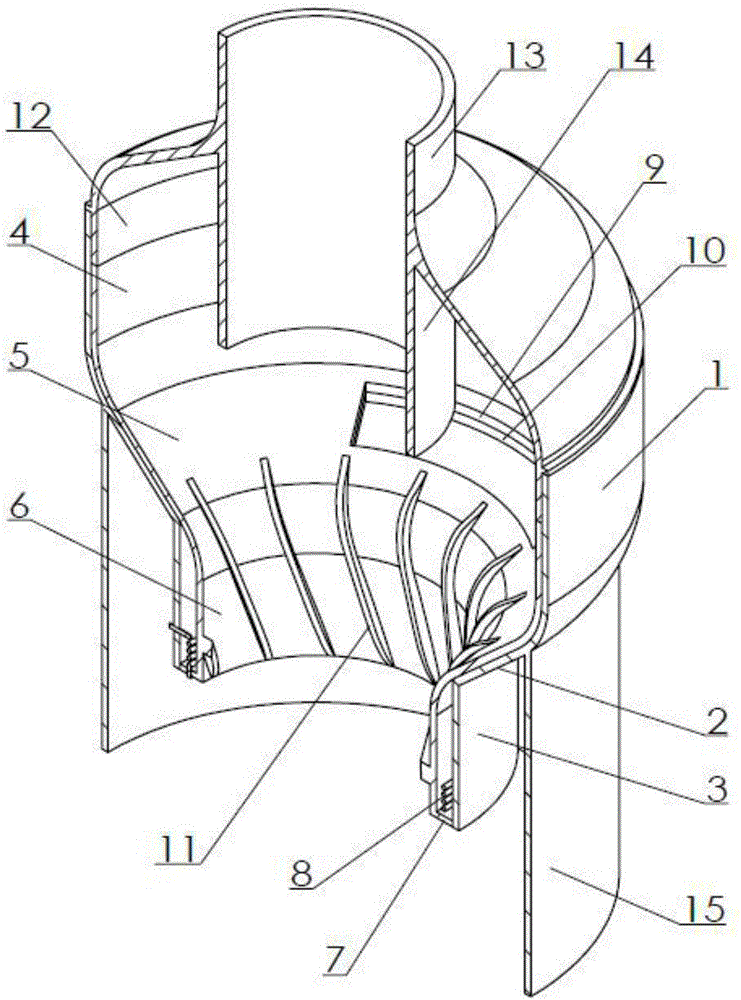

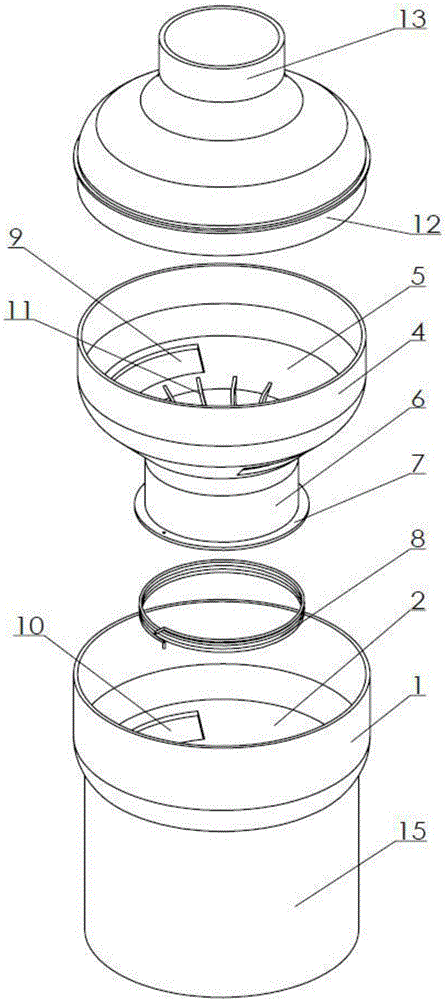

[0011] Examples of the present invention figure 1 , 2 As shown, this constant flow valve for automatic adjustment of oil delivery flow includes a valve body, a valve core and a valve cover. Outer cone 2, the lower section connected to the cone is the lower cylinder 3, the valve core is provided with an inner cylinder 4 that is placed in the upper cylinder and fits with the upper cylinder, and the inner cylinder is connected with a clearance fit with the outer cone The lower end of the inner cone is connected with an inner cylinder 6 coaxial with the lower cylinder, an annular gap is kept between the inner wall of the lower cylinder and the outer wall of the inner cylinder, and the lower end of the inner cylinder is connected with a protruding and lower cylinder. The ring-shaped outer edge 7 fits the inner wall of the cylinder, and the valve core can rotate freely. There is a torsion spring 8 in the annular gap. One end of the torsion spring is connected to the ring-shaped out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com