Cap mounting structure

一种安装结构、盖子的技术,应用在运输和包装、车辆部件等方向,能够解决损害外观、模具结构复杂、盖子不能滑动等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

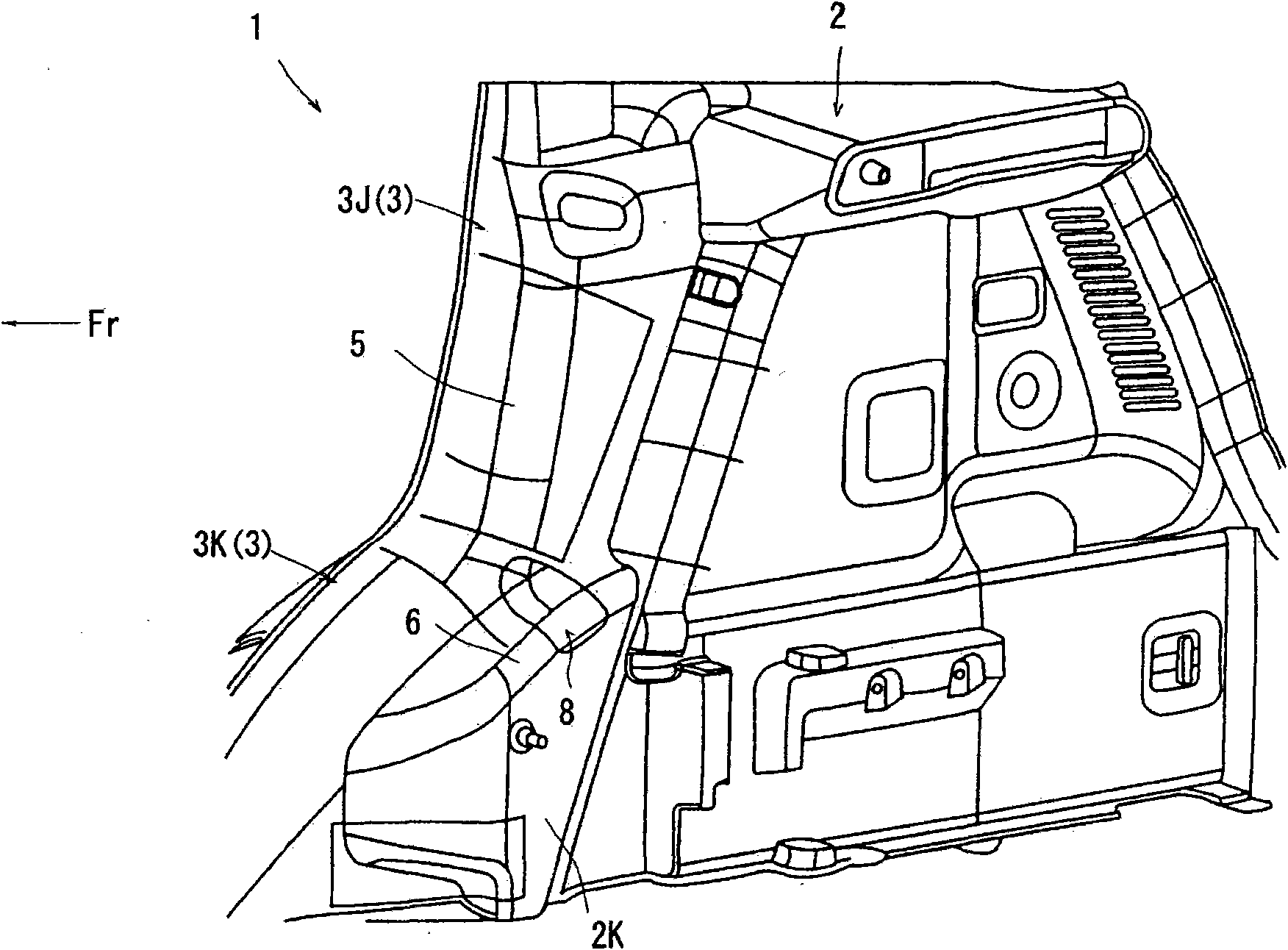

[0040] figure 1 A trunk trim 1 (corresponding to an interior component) of a motor vehicle is shown. The rear trunk trim 1 includes a trapezoidal side wall portion 2 and a front wall portion 3 extending from the front end portion of the side wall portion 2 to the outside in the vehicle width direction, the rear trunk trim 1 covering the cargo box (the rear trunk) behind the rear seat. ). The front wall portion 3 is arranged such that a lower half 3K thereof is formed in a quarter-arc shape convex forward and upward, and an upper half 3J extends obliquely rearward and upward from an upper end portion of the lower half 3K. Front end portions of the lower half 3K of the front wall portion 3 and the lower half 2K of the side wall portion 2 cover the wheel housing.

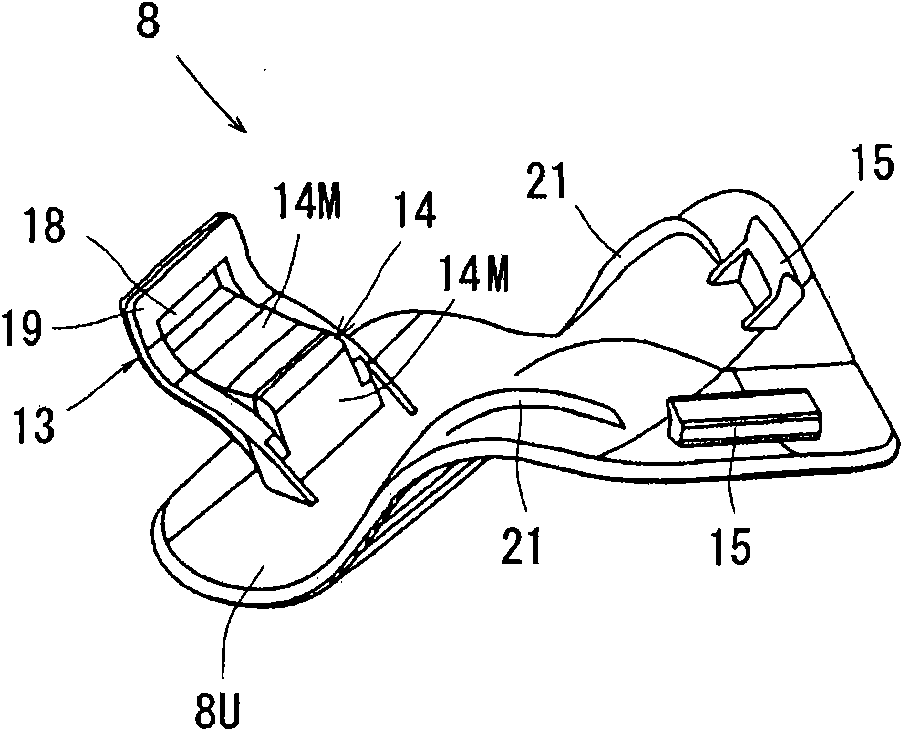

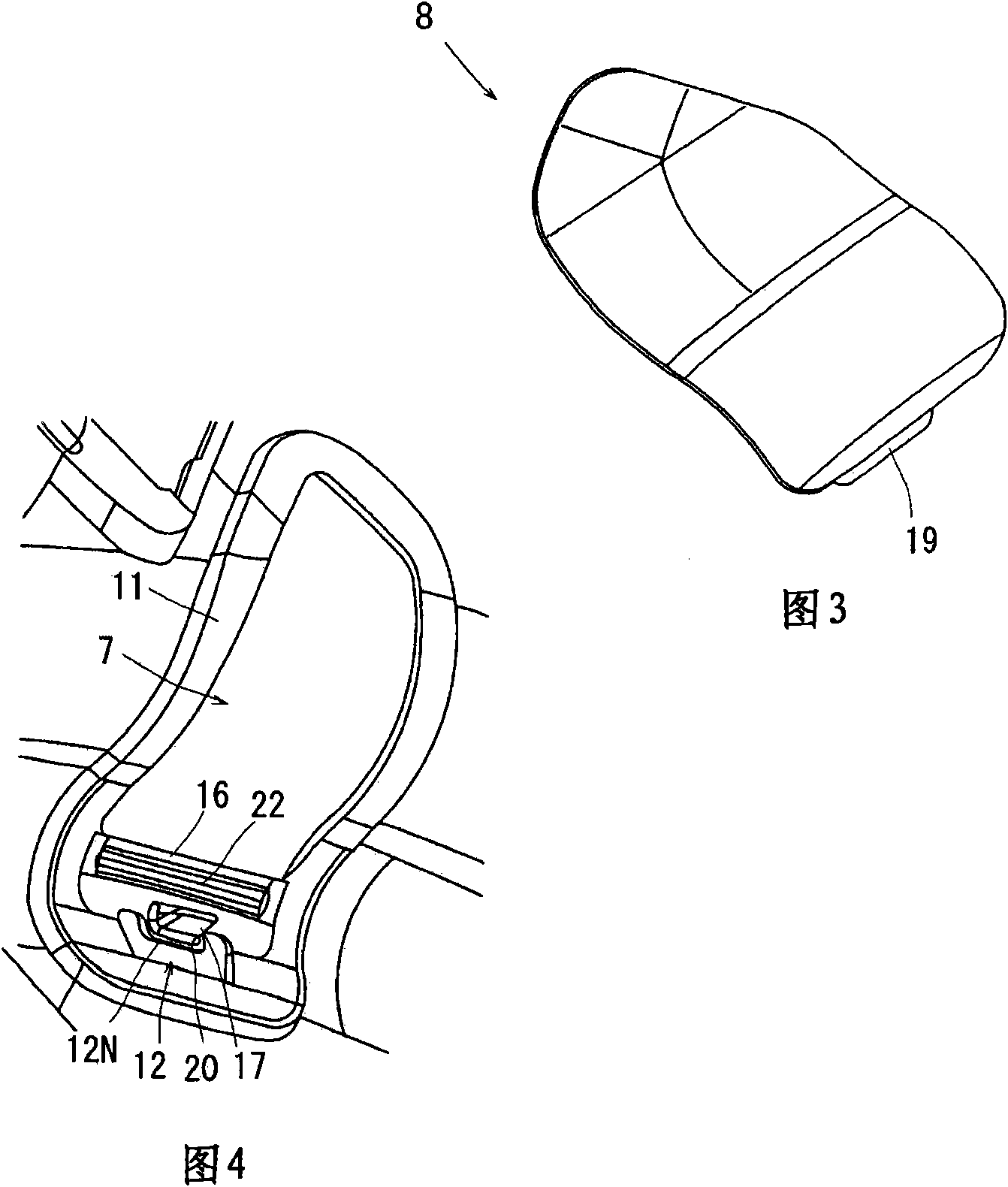

[0041] As shown in FIG. 5( a ), in the upper half 3J of the front wall portion 3 , a large first o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com