A large-size reinforced display terminal and its bonding process

A display terminal and large-size technology, which is applied in the field of large-size reinforced display terminal and its bonding process, and can solve problems such as increasing the thickness of the display terminal, broken glass of the display terminal, and damage to the LCD screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the invention.

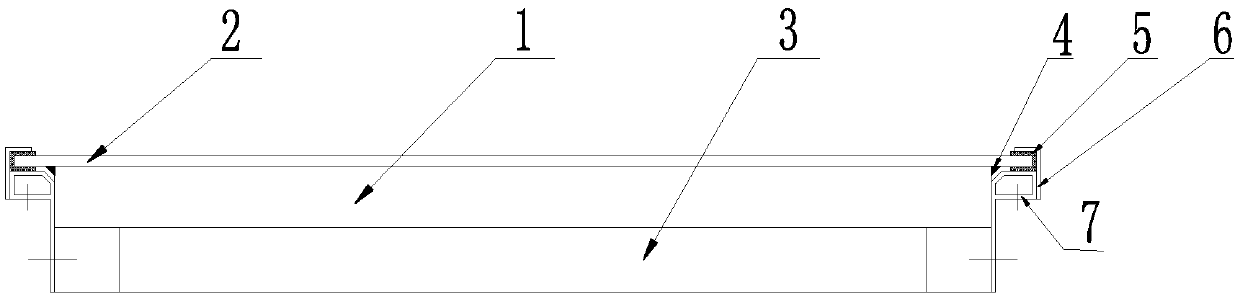

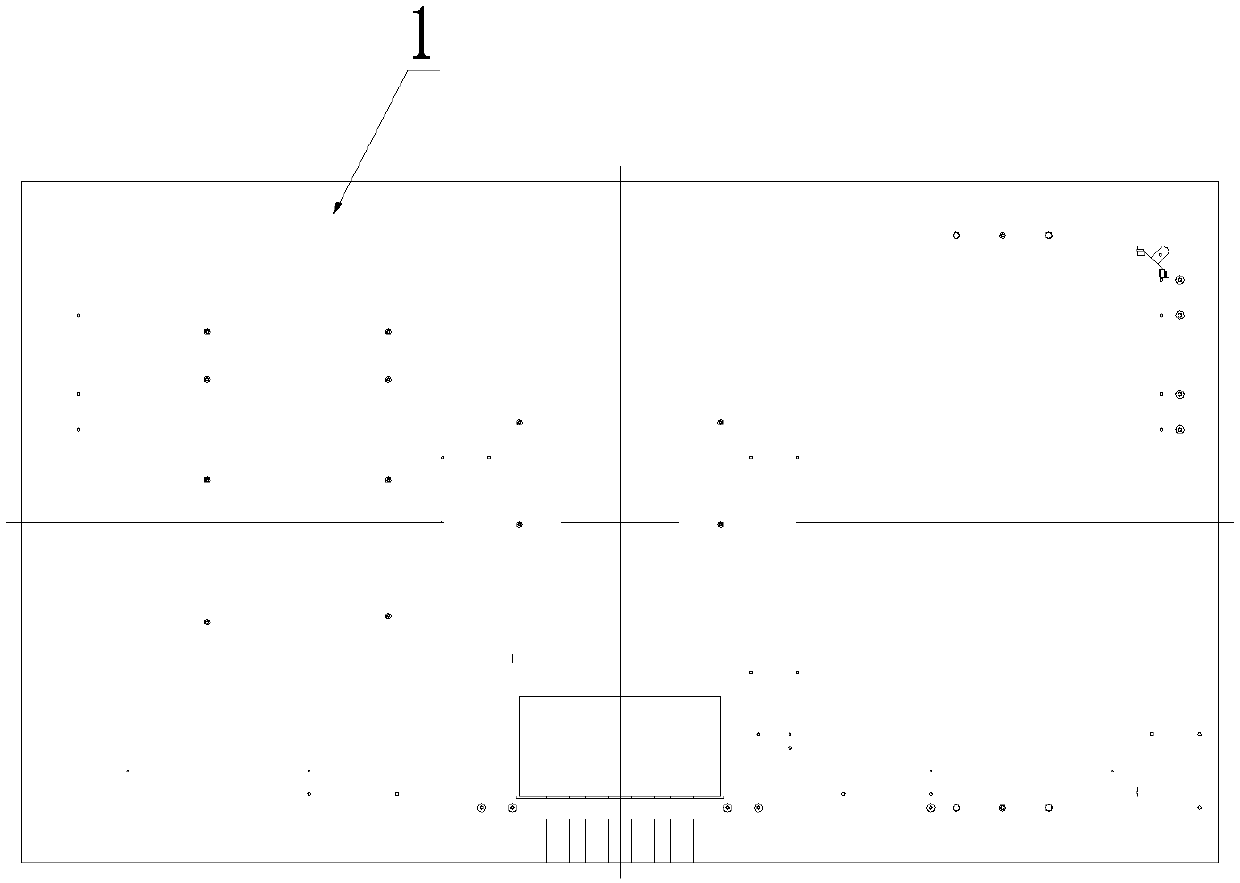

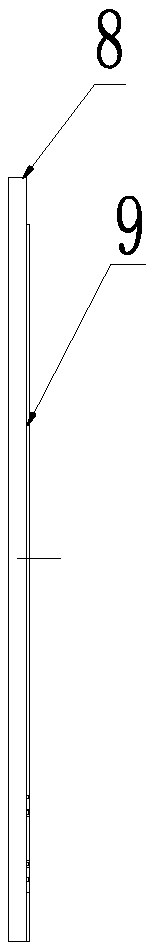

[0020] The present invention provides a large size reinforced display terminal, the structure of the large size display terminal is as follows figure 1 , 3A , 3B, including a large-size display 1, the front of the display 1 is sealed and bonded to an ITO (Indium Tin Oxides, indium tin oxide) shielding glass 2 through an adhesive structure 4, and the periphery of the ITO shielding glass 2 is sealed by a U-shaped conductive rubber 5 . Among them, the viscous structure 4 is made of silica gel with high ductility and high temperature resistance. The back of the display 1 is provided wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap