Securing the shaft in a cone crusher

A cone crusher and cone technology, applied in grain processing and other directions, can solve the problems of difficult to remove the main shaft, complicated cone support, etc., to avoid the difficulty of positioning the oil pipe, avoid the complicated removal and installation, and the large clamping force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

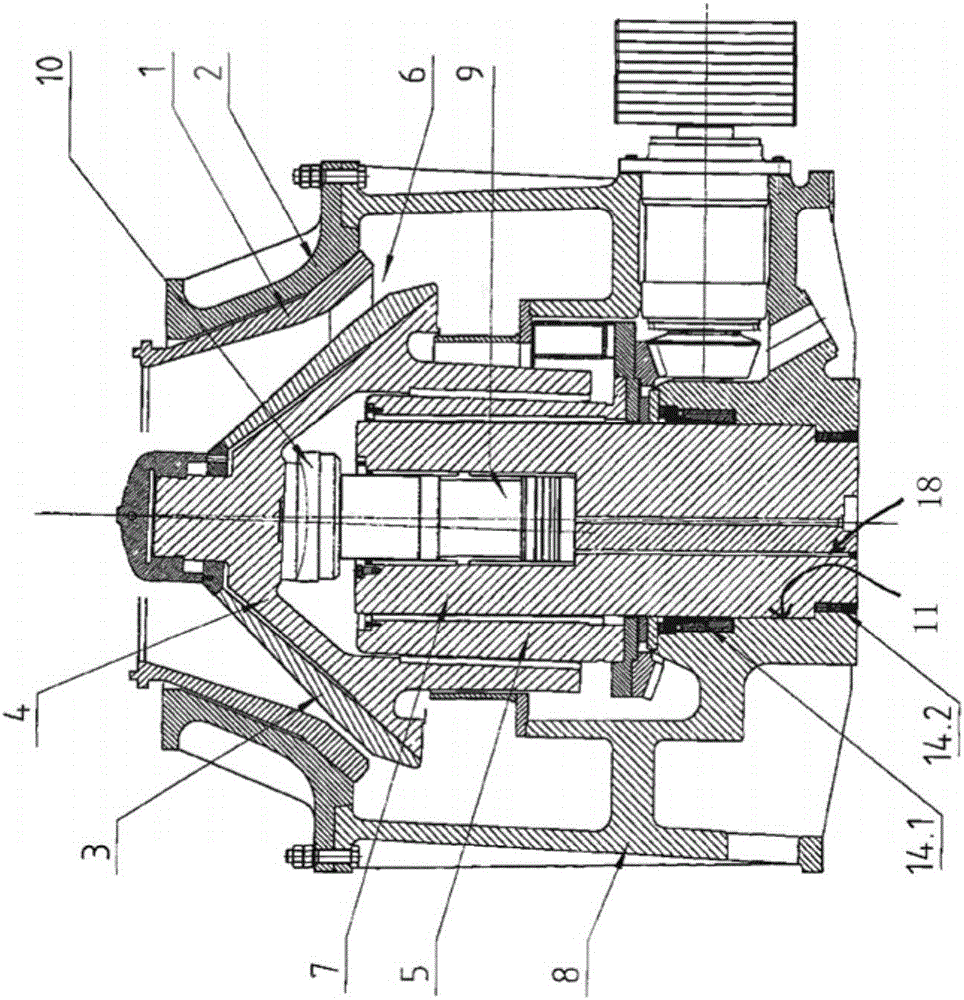

[0022] first figure 1 A section through the head of a cone crusher according to the invention is shown. The material for crushing supplied to the cone crusher is crushed between the stationary crushing ring 1 of the upper part 2 of the housing and the crushing cone 3 sitting on the conical seat of the cone carriage 4 . The cone carrier 4 is set in an oscillating movement via the driven eccentric bushing 5, with the result that the crushing gap 6 between the crushing ring 1 and the crushing cone 3 changes in a continuously rotating manner. In the crushing gap 6 the material for crushing is comminuted by extrusion and impact until said material is able to leave the cone crusher through the crushing gap 6 .

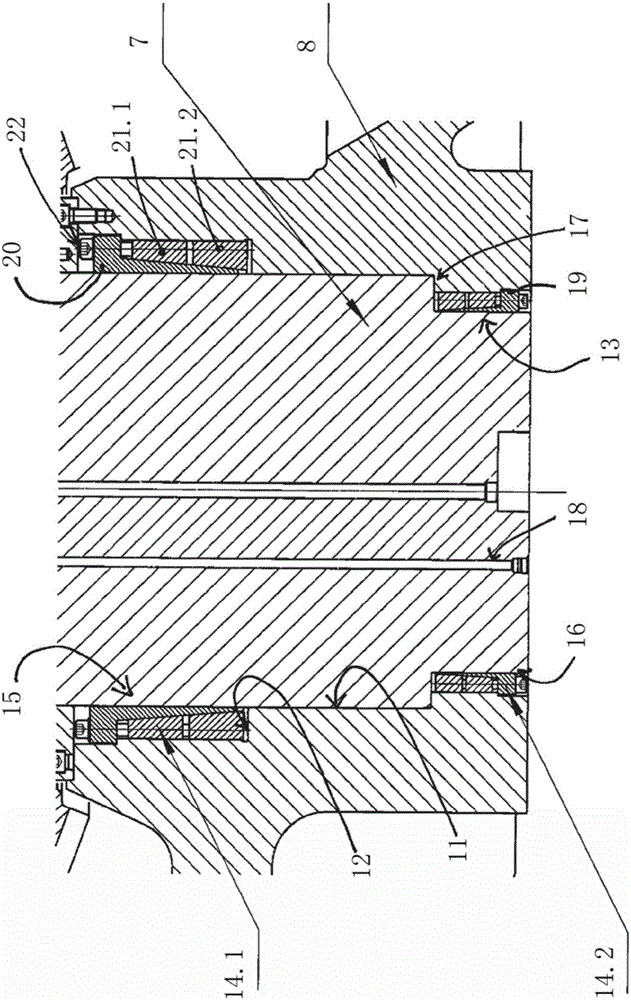

[0023] The driven eccentric bushing 5 rotates and is guided radially about a main shaft 7 which is fixedly clamped in the housing lower part 8 . For the axial support of the cone carrier 4 , a spherical thrust bearing 10 is used which is arranged on the head of the cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com