A slow-down device for a toilet cover

The technology of a slow-down device and toilet lid, applied in the field of sanitary ware, can solve the problems of complex manufacturing process, small oil flow, complex assembly, etc., and achieve the effect of simple manufacturing process, simple assembly, reliable and convenient opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

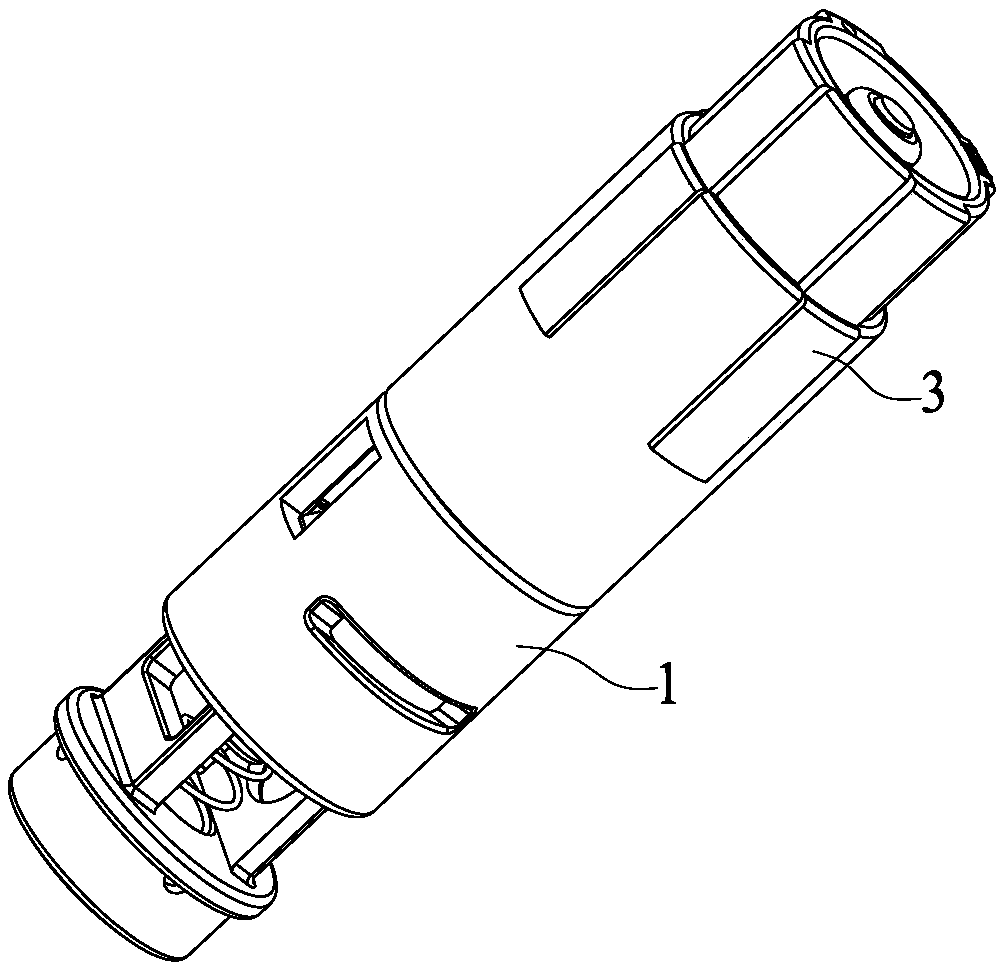

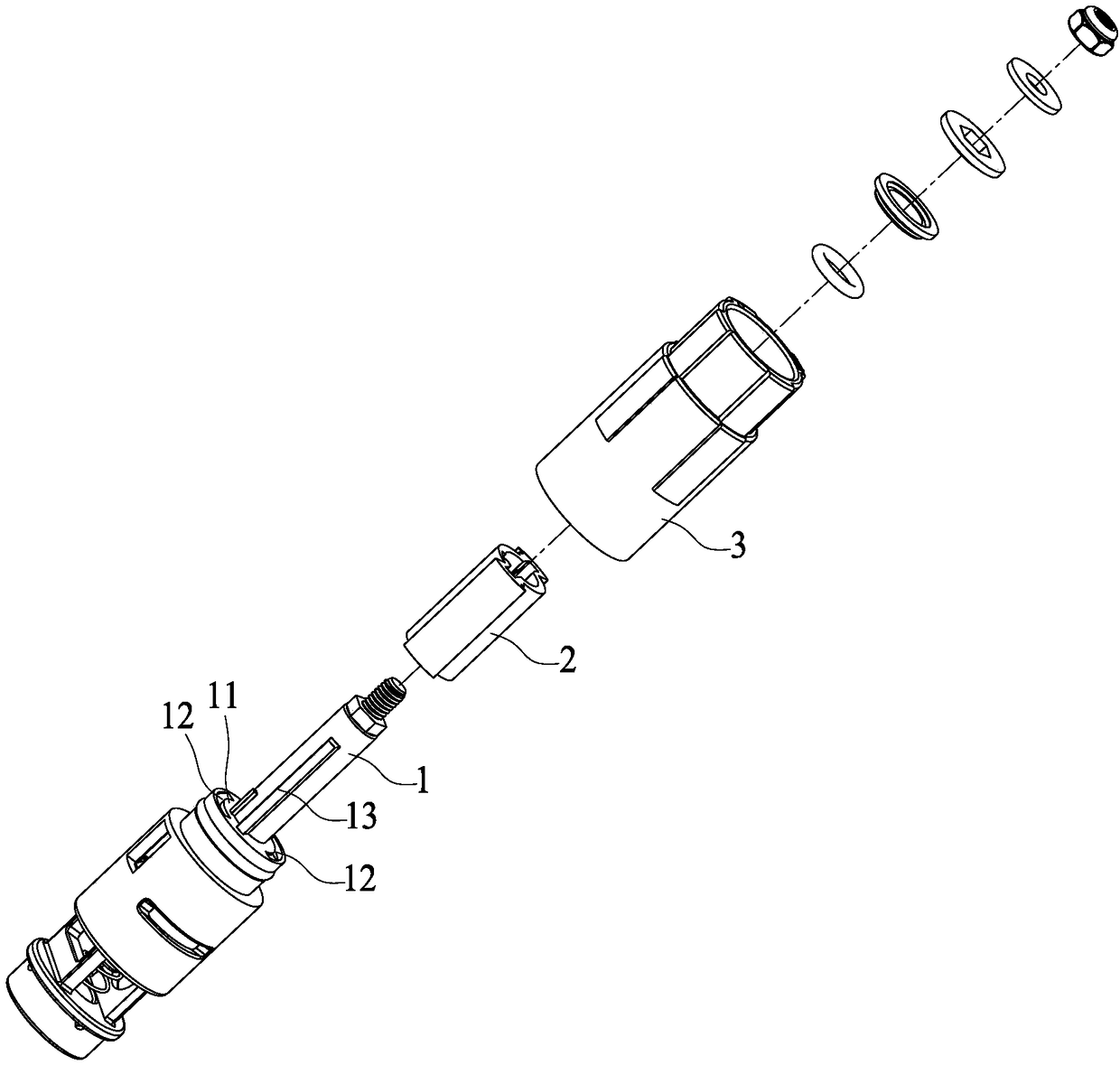

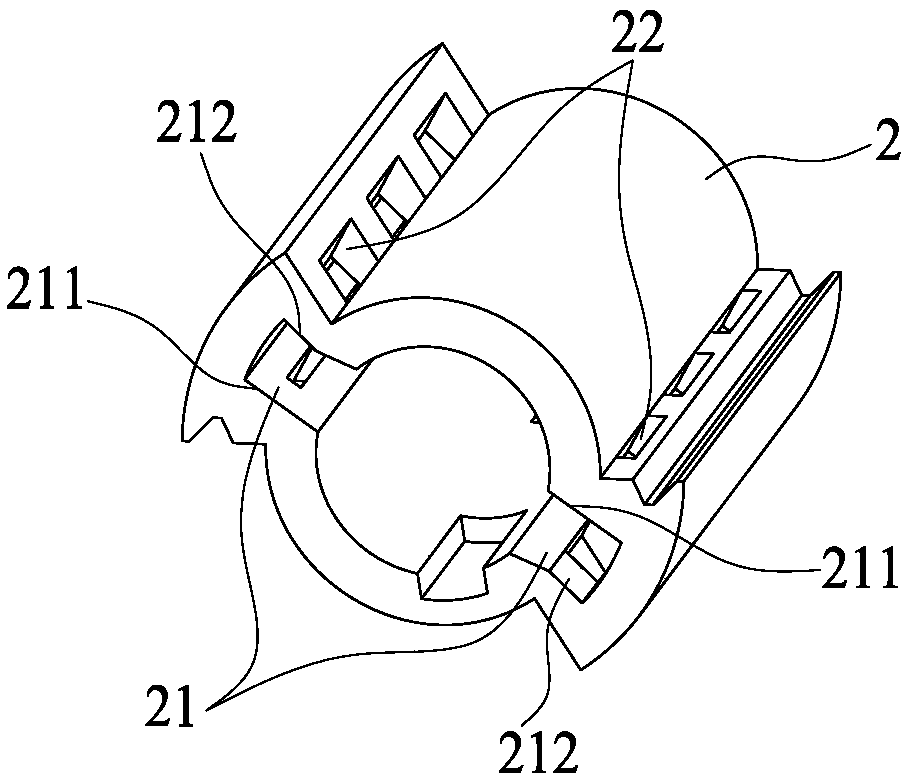

[0034] see Figure 1 to Figure 7a As mentioned above, a toilet cover slow-down device disclosed by the present invention includes a rotating shaft 1 , a blade 2 and a shaft sleeve 3 .

[0035] One end of the rotating shaft 1 forms a radial end surface 11, and an oil passage 12 is arranged on the radial end surface 11. The oil passage 12 has a large oil inlet and a small end. In this embodiment, two oil passage grooves 12 are arranged. The center of the oil passing groove 12 is arranged symmetrically. The oil passing groove 12 changes from shallow to deep along the counterclockwise direction and / or the groove diameter changes from small to large along the counterclockwise direction. The slower the speed.

[0036] Ribs 13 protrude along the axial direction on the rotating shaft 1; Figure 4 As shown, in this embodiment, two ribs 13 of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com