One-step individually molded dental implant

A dental implant, a one-time technology, applied in dentistry, dental implants, dental prosthetics, etc., can solve the problems of poor contact between the tooth and the bone, easy to loose, poor contact, etc., to achieve good contact and repulsive force. Small, the effect of prolonging the use cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

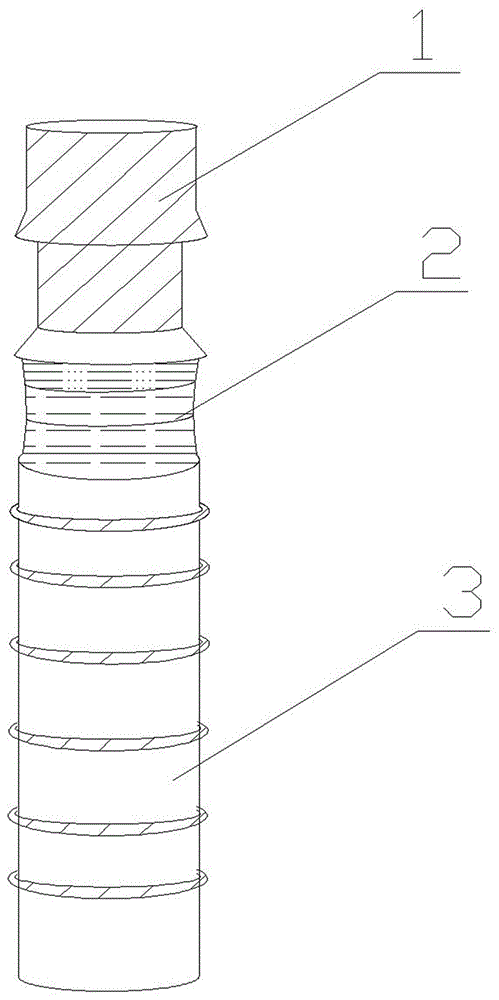

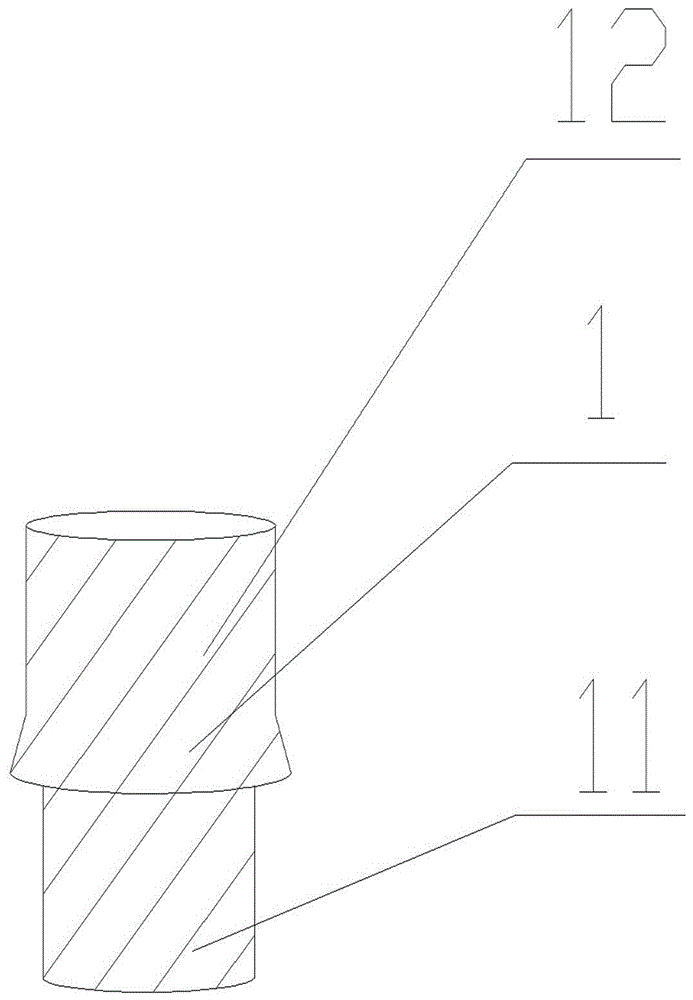

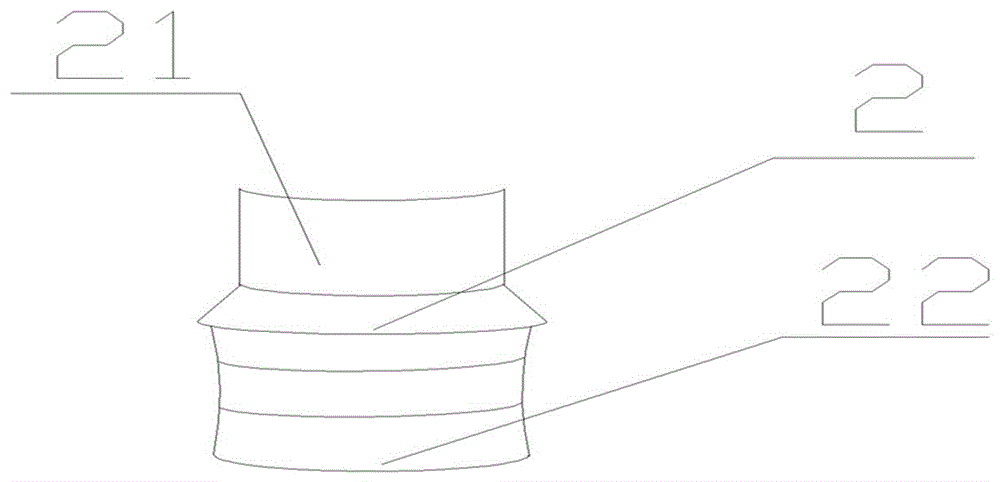

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a disposable personalized plastic dental implant includes a gingival former 1, a gingival retainer 3, and a connecting piece 2 between the gingival former 1 and the gingival retainer 3; the gingival former 1 is a middle Empty tube body, the gingival former 1 includes an integrally formed gingival former upper part 12 and a gingival former lower part 11, the shape of the gingival former upper part 12 is adapted to the shape of the crown; the connector 2 includes an integrally formed connector upper part 21 and The lower part 22 of the connector, the shape of the upper part 21 of the connector is adapted to the shape of the upper part 12 of the gingival former, the outer surface of the lower part 22 of the connector is provided with external threads, the inner surface of the upper end of the gingival retainer 3 is provided with internal threads, the lower part of the connector 22 Threaded connection with gin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com