Electric oven heating wire rack and its manufacturing process

A technology of electric oven and wire rack, which is applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc. It can solve the problems of uneven temperature of electric oven, uneven distribution of hot wire, inaccurate spacing distance, etc., and achieve structural The effect of compactness, uniform distribution, and precise spacing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

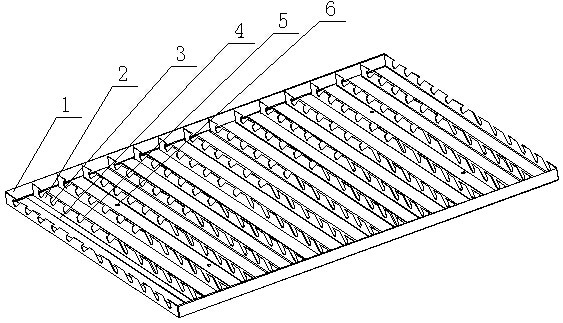

[0026] Such as figure 1 As shown, the heating wire frame of the electric oven of the present embodiment includes a heating wire frame of an integrated structure, a surrounding frame 1 is arranged on the periphery of the heating wire frame, and a plurality of horizontal underframes 4 are evenly distributed inside the surrounding frame 1, One side of each horizontal bottom frame 4 is extended with a vertical frame 2, and a plurality of oblique notches 3 are opened on the vertical frame 2.

[0027] The oblique notches 3 on each vertical frame 2 are distributed symmetrically.

[0028] Positioning holes 6 are provided on two of the horizontal underframes 4 .

[0029] A drain 5 is formed between two adjacent horizontal underframes 4 .

[0030] The hot wire frame is made of a whole piece of sheet metal.

[0031] The cross-section of the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com