Machining tool suitable for thrust block of thrust bearing

A technology of thrust bearings and thrust blocks, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of difficult clamping and positioning of thrust blocks, and achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] In order to understand this solution more clearly, here is a brief description of the thrust block.

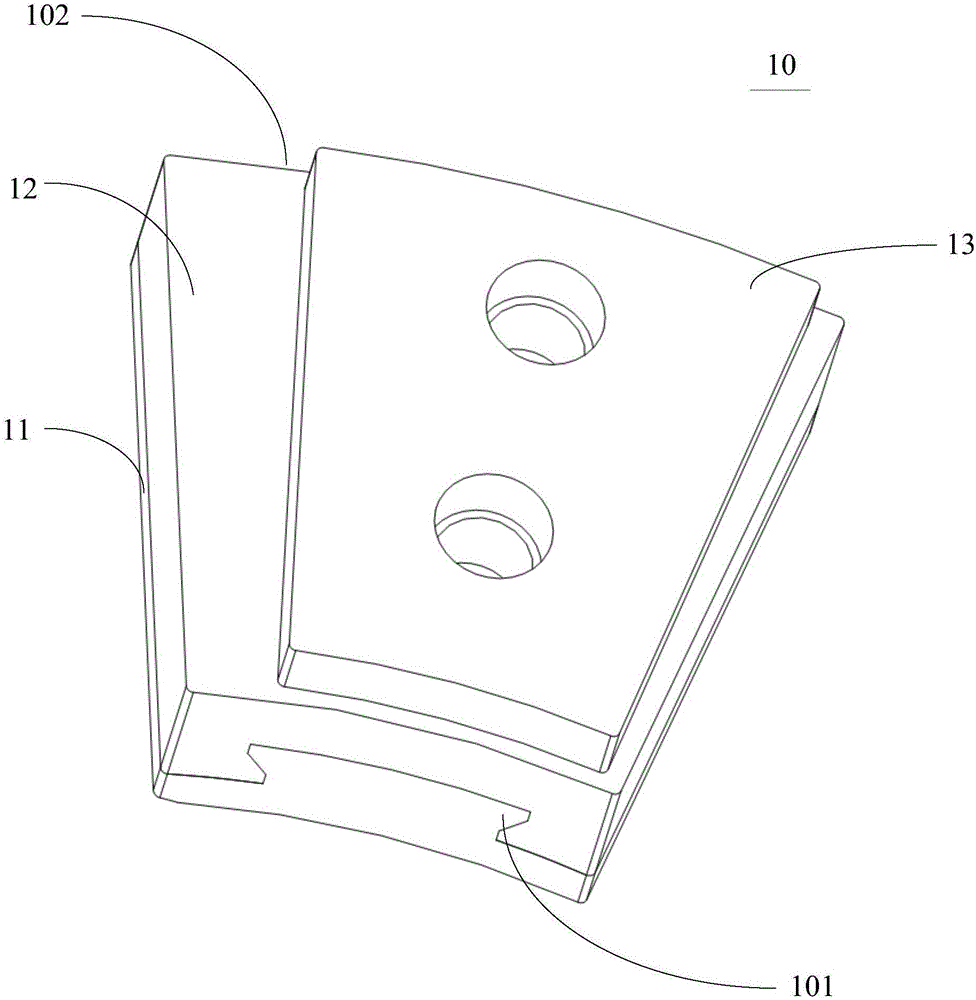

[0031] figure 1 It is a structural diagram of a thrust block of a thrust bearing provided by an embodiment of the present invention. The thrust block 10 includes a stacked tile surface 11, a tile base body 12 and a rubber body 13, wherein the tile surface 11 and the rubber body 13 are made of rubber. The tile surface 11, the tile base body 12 and the rubber body 13 are all fan-shaped, and the arc length of the rubber body 13 is smaller than the arc length of the tile base body 12, so that the top surface of the thrust block 10 forms a set of stepped surfaces, and the thrust block 10 sets The opposite sides are the first arc-sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap