Transfer printing method

A technology of transfer printing and printing film, applied in the directions of copying/marking methods, printing, printing devices, etc., can solve the problems of low printing efficiency, waste of glue, large energy loss, etc., and achieve high production efficiency, good adhesion, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

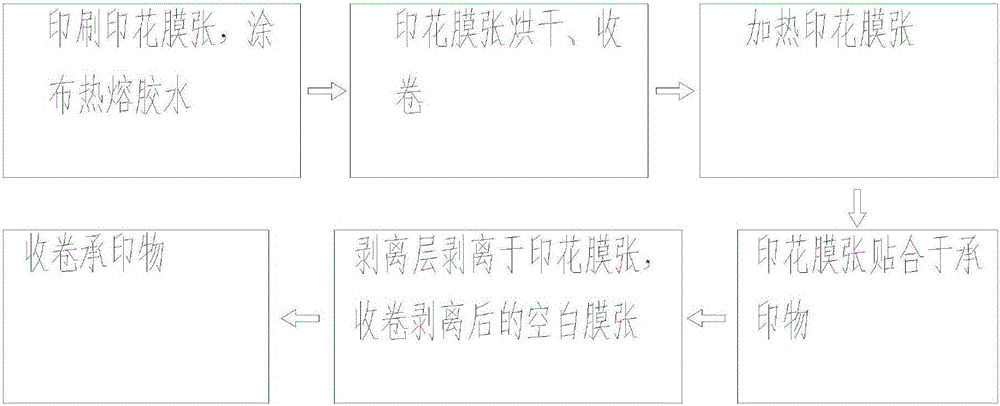

[0043] A transfer printing method, comprising the following steps:

[0044] (1) Printing and printing film sheets, coating hot melt glue;

[0045] 1.1) Coating a release layer on the printing film;

[0046] 1.2) Print the decal pattern onto the release layer;

[0047] 1.3) Coating hot melt glue on the printed pattern printed on the peeling layer;

[0048] (2) The printing film is dried and rolled;

[0049] (3) using a heating device to heat the printed film sheet;

[0050] (4) Paste the printing film on the substrate;

[0051] (5) The peeling layer is peeled off from the printed film sheet, and the blank film sheet after the stripping is rewound;

[0052] (6) Rewind the substrate.

[0053] Further, in step (1), after the printing is printed on the peeling layer, before the hot melt glue is applied, the pearlescent pigment or metallic pigment is printed on the printing film.

[0054] Further, the etching depth of the mold used for printing the decal sheet in step (1) is ...

Embodiment 2

[0064] In this embodiment, the heating device for heating the printed film sheet in step (3) is an infrared heating device. Except for this, other steps and implementation methods are the same as those in Example 1.

Embodiment 3

[0066] In this embodiment, the heating device for heating the printing film sheet described in step (3) is a hot air stove heating device. Except for this, other steps and implementation methods are the same as those in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap