Automobile rear side window area reinforcing structure and automobile

A technology for strengthening structure and window area, applied in the directions of superstructure, superstructure sub-assemblies, vehicle components, etc., can solve the problems of difficult design and complex structure of the rear side window area, and achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

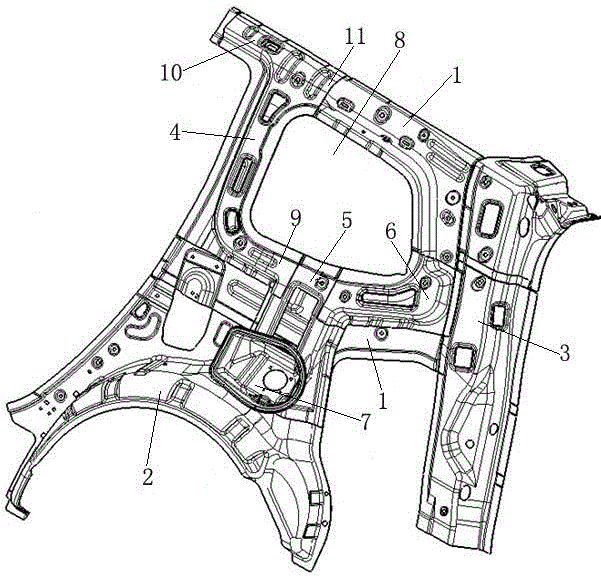

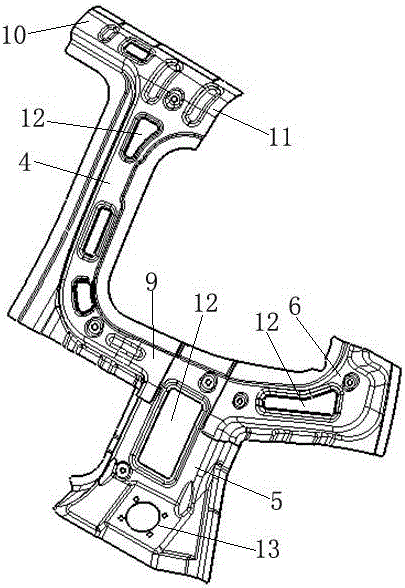

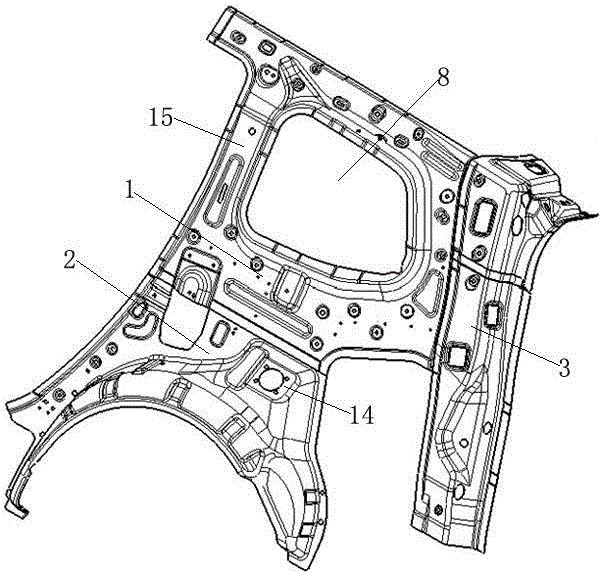

[0023] like figure 1 The rear side window area reinforcement structure of a car shown includes a rear side wall inner panel 1, a rear wheel house outer panel 2 lapped on the lower side of the rear side wall inner panel 1, and a rear wheel house outer panel 2 lapped behind the rear side wall inner panel 1. The side D-pillar reinforcement 3, the upper part of the rear side wall inner panel 1 has the rear side window 8, the rear side wall inner panel 1 is formed with the C-pillar inner panel 15 on the front side of the rear side window 8, the rear side wall inner panel 1 The face facing the outside of the car is lapped like figure 2 As shown in the reinforcement assembly, the reinforcement assembly forms a cavity reinforcement structure on the rear side wall inner panel 1, and the reinforcement assembly includes a first vertical extension section lapped on the C-pillar inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com