Method for establishing photo-Fenton system for tetracycline degradation based on composite bismuth ferrite material

A composite material, bismuth ferrite technology, applied in the field of water treatment, can solve the problems of low efficiency and achieve the effect of improving utilization rate and degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

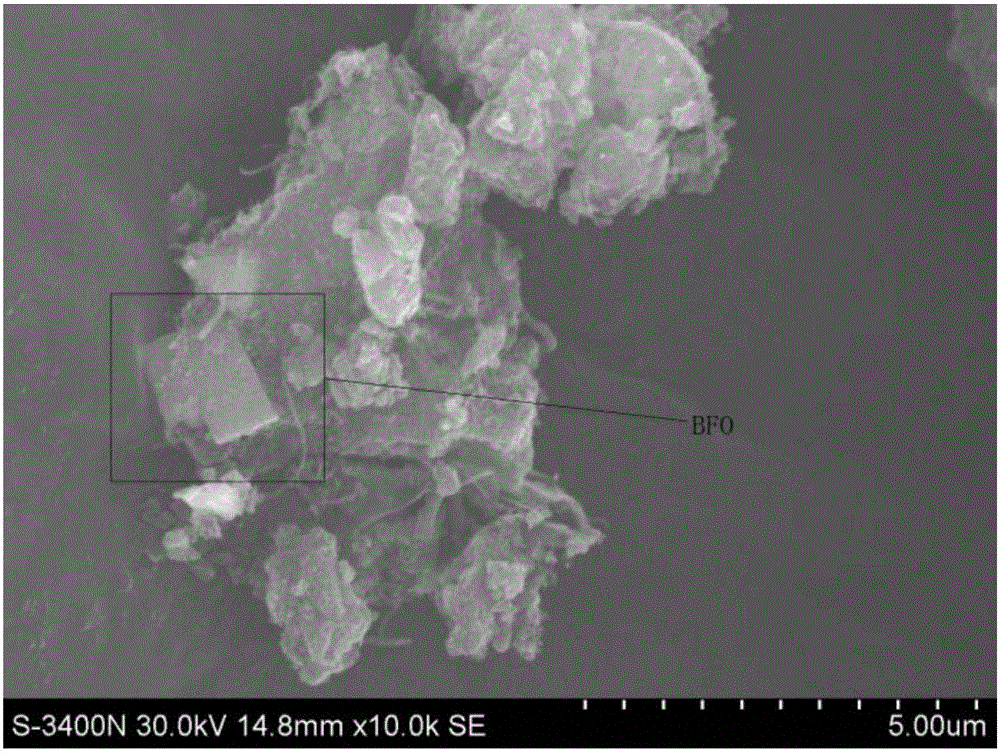

[0038] Graphite oxide was prepared by the Hummers method: 10.0 mL of concentrated sulfuric acid solution containing 5.0 g of potassium persulfate and 5.0 g of phosphorus pentoxide was heated to 80 °C, 10.0 g of graphite powder was added to it for pre-oxidation for 6 h, cooled and washed until neutral. Under ice-bath conditions, the obtained material was added to 230.0 mL of concentrated sulfuric acid solution, and then 30.0 g of potassium permanganate was slowly added. Adjust the temperature of the mixed solution to 25°C and react for 2 hours, add 1.0L deionized water and 25.0mL 30% oxygen peroxide to it, wash and dialyze after the reaction is complete, then collect and dry to obtain graphene oxide solid. The bismuth ferrite composite material is prepared by an alkaline hydrothermal method, and the preparation method is as follows: 1.5 g of bismuth nitrate and 1.2 g of ferric chloride are added to 5.0 mL of a 10% sodium nitrate solution. A sodium hydroxide solution with a conc...

Embodiment 2

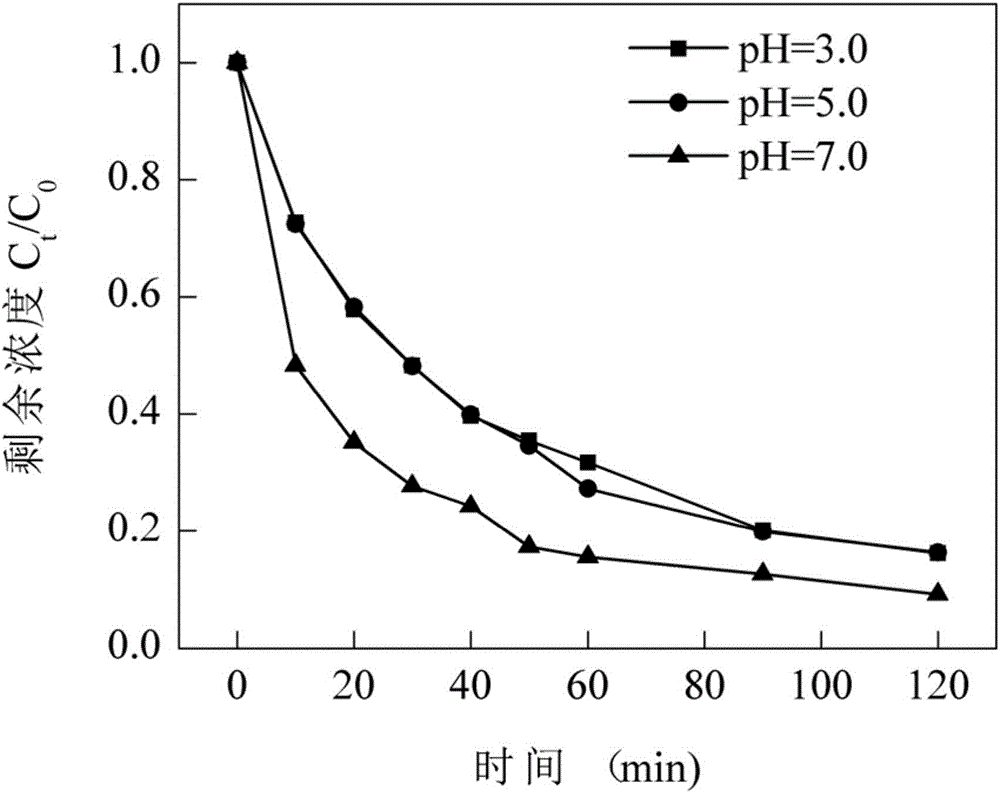

[0041] (1) The bismuth ferrite composite material that embodiment 1 makes is dropped into the tetracycline solution of 20.0mg / L, and composite material concentration is 0.5g / L;

[0042] (2) Adjust the pH value of the solution to 3.0, 5.0 and 7.0, turn on the magnetic stirrer, and mix the material with the solution for 60 minutes;

[0043] (3) Turn on the xenon lamp to start the photocatalytic reaction;

[0044] (4) Sampling during the reaction process, the sample uses a filter membrane to remove the composite material, and the concentration of tetracycline in the remaining solution is measured by high performance liquid chromatography. After the photocatalytic reaction continues for 120min, the detection tetracycline removal rate is 83.9%, 83.7% and 90.8%, respectively, See figure 2 .

Embodiment 3

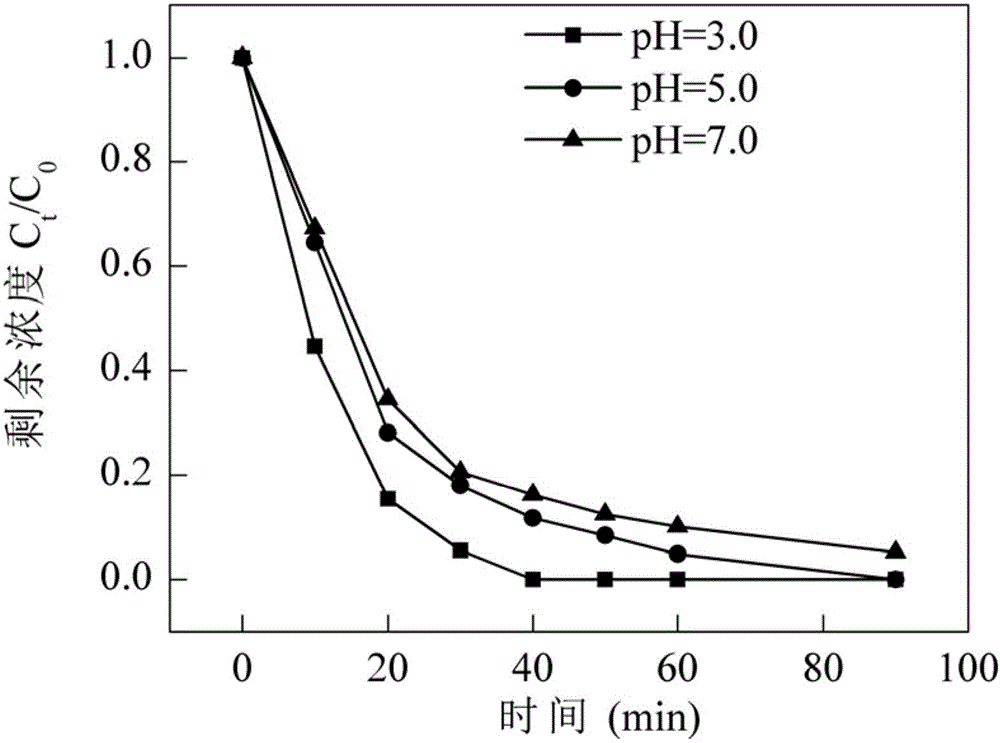

[0046] (1) The bismuth ferrite composite material that embodiment 1 makes is dropped into the tetracycline solution of 20.0mg / L, and composite material concentration is 0.5g / L;

[0047] (2) Adjust the pH value of the solution to 3.0, 5.0 and 7.0, turn on the magnetic stirrer, and mix the material with the solution for 60 minutes;

[0048] (3) Dosing H 2 o 2 Aqueous solution, H in solution 2 o 2 The concentration is 0.5mmol / L;

[0049](4) Sampling in the reaction process, after the sample uses the filter membrane to remove the composite material, measure the tetracycline concentration in the remaining solution by high performance liquid chromatography, after the reaction continues for 120min, the detection tetracycline removal rate is respectively 69.5%, 63.4% and 40.1%, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com