A method of improving the service life of cold rolling pipe mill passes

A technology of cold-rolled tubes and machine holes, applied in the field of cold-rolling of metal pipes, can solve the problems of restricting production efficiency, increasing rolling costs, and low service life, reducing rolling costs, improving the service life of pass shapes, and improving resistance to corrosion. The effect of fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] A kind of method that the present invention provides to improve the pass life of cold-rolled pipe mill comprises the following steps:

[0020] The first step is to carry out trial rolling to the finished cold-rolled pass 1 after fine grinding, to ensure that the cold-rolled pass 1 meets the rolling quality requirements, that is, to ensure that the cold-rolled pass 1 made by the trial rolling meets the design requirements;

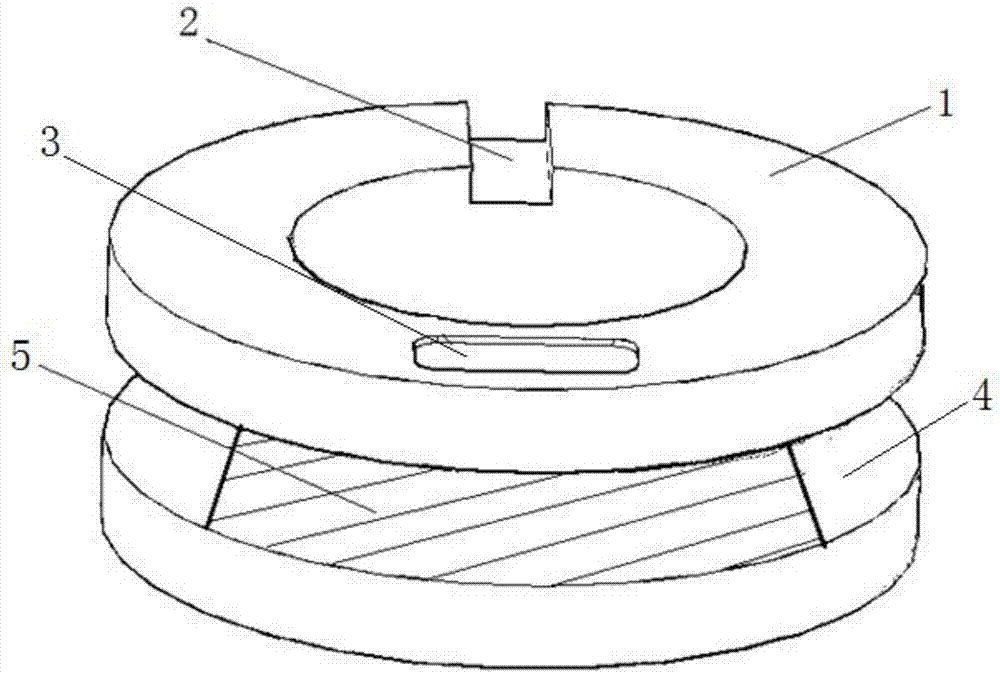

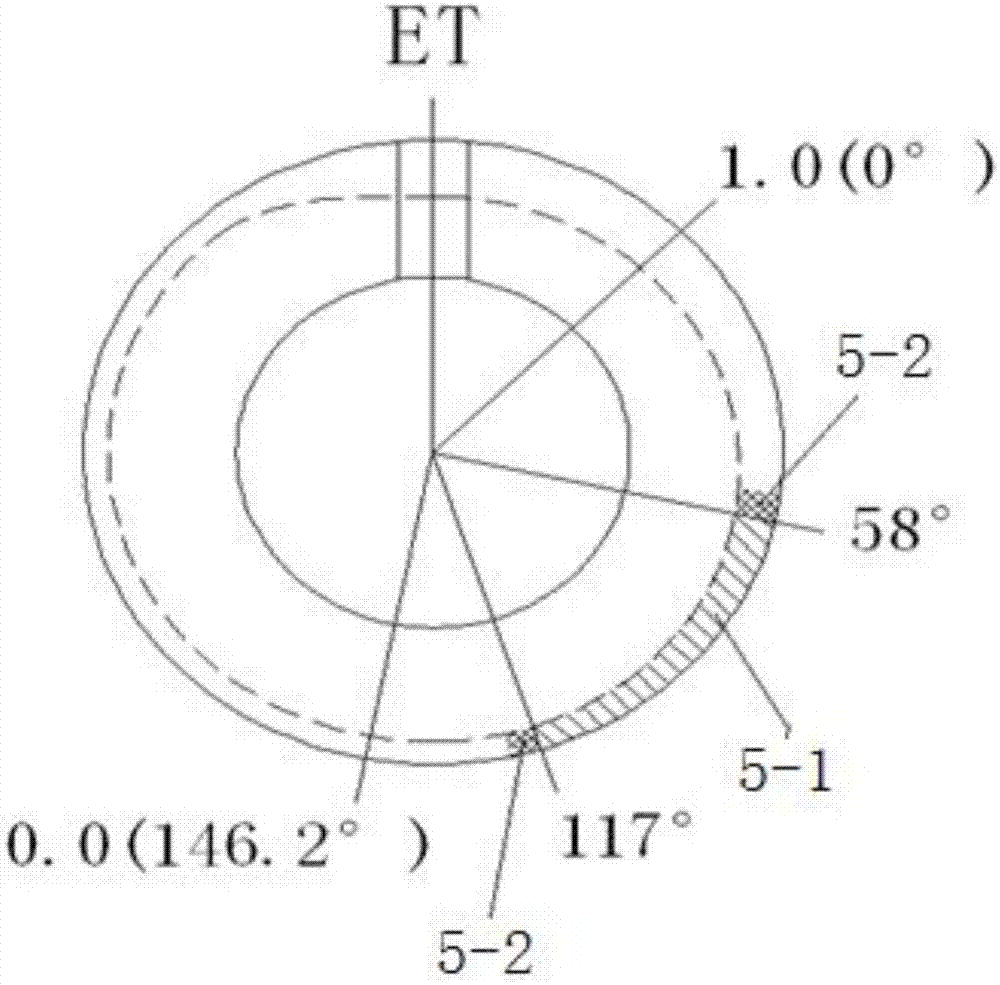

[0021] The second step, see figure 1 and figure 2 , the pass 1 is provided with a keyway 2, a marking area 3 and a pass groove 4. According to the position of the pass groove 4, the maximum stress area of the pass groove 4 is regarded as the laser shock strengthening area 5-1, and in the laser shock strengthening area 5 An area is added on both sides of -1 as the laser shock strengthening boundary transition ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com