Intake pressure sensor of motorcycle

A technology of air intake pressure and motorcycle, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of reducing the reliability of the intake pressure sensor, affecting the measurement accuracy, shaking or displacement of the pin, etc., to improve Effects of measurement accuracy and reliability, improvement of measurement accuracy and reliability, and improvement of airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

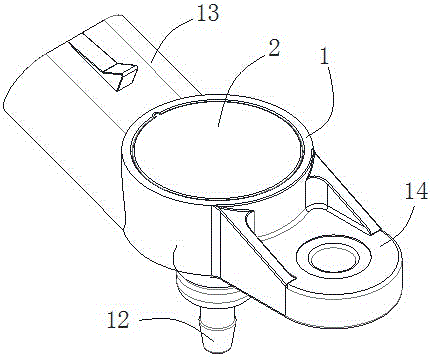

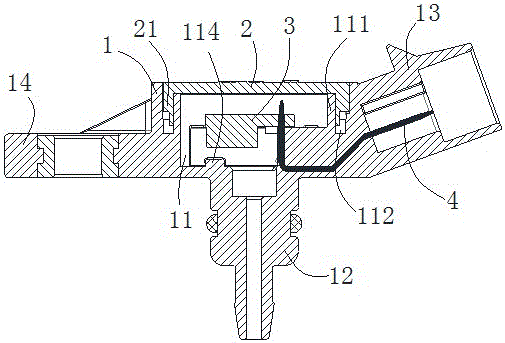

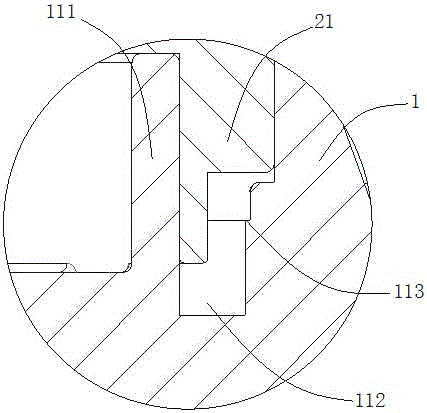

[0032] During specific implementation: if Figure 1~Figure 3 As shown, a motorcycle air intake pressure sensor includes a housing 1 and a cover plate 2. The housing 1 has a storage chamber 11 with an open upper end, and the lower end of the storage chamber 11 is provided with an air intake connection end 12. The air intake connection end 12 has an air intake hole communicating with the bottom of the storage chamber 11; the cover plate 2 can be hermetically fitted at the opening at the top of the storage chamber 11; the storage chamber 11 has A circle of baffles 111 arranged equidistantly from the side walls of the storage cavity, a sealing groove 112 is formed between the baffles 111 and the side walls of the storage cavity 11; the edge of the cover plate 2 extends to one side to form a The convex edge 21 corresponding to the sealing groove 112 is completely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com