Fixed shadow belt, fixed shadow device and image formation device

A technology of fixing belt and image, applied in the field of fixing device, image forming device, and fixing belt, can solve the problems of uneven gloss, not considering the reduction range of temperature, difference, etc., and achieve the effect of suppressing uneven gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

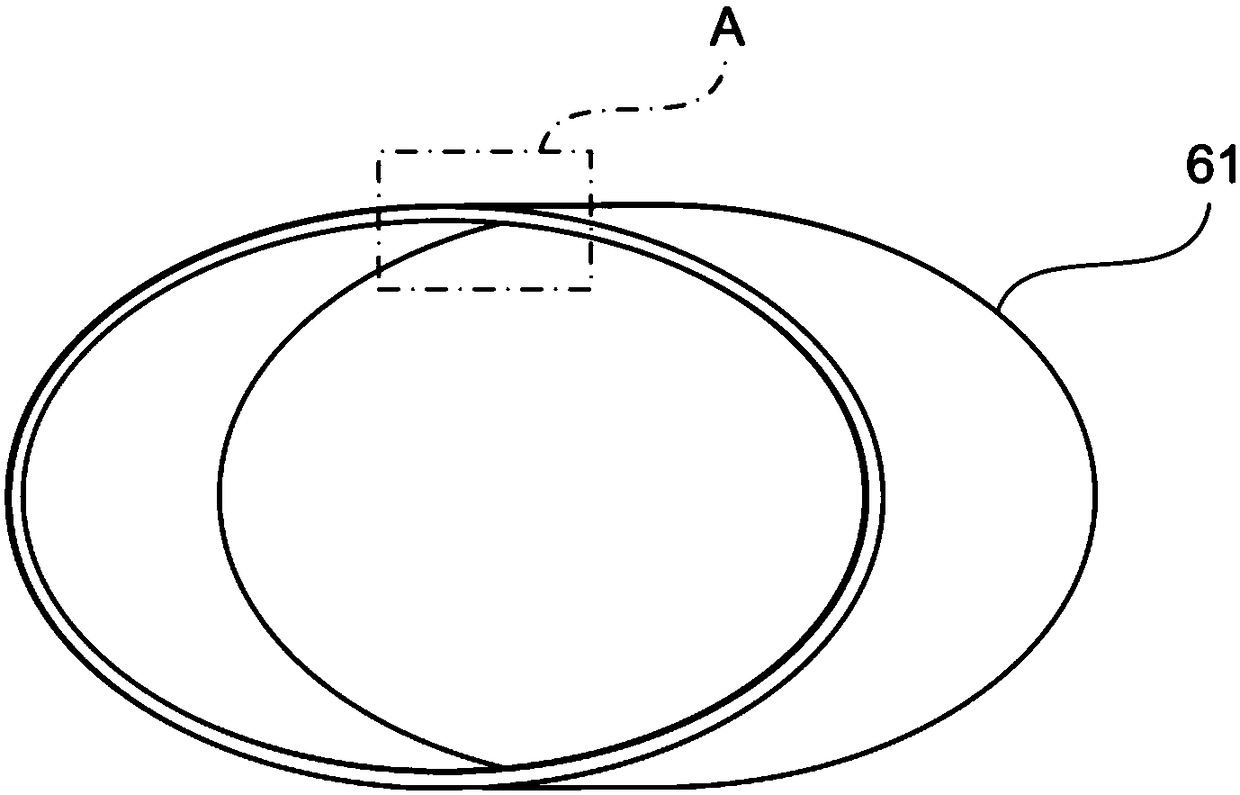

[0106] A cylindrical mandrel made of stainless steel with an outer diameter of 60 mm was closely adhered to the inside of a tape base material made of a thermosetting polyimide resin with an inner diameter of 99 mm, a length of 360 mm, and a thickness of 70 μm. Next, on the outer side of the belt base material, a cylindrical mold holding a PFA tube with a thickness of 30 μm is covered on the inner peripheral surface, so that the mandrel and the cylindrical mold are coaxially held, and a space is formed between the two. cavity. Next, the silicone rubber material A was injected into the cavity, heat-cured, and an elastic layer of the silicone rubber A with a thickness of 200 μm was produced. In this way, the fixing belt 1 was produced in which the belt base material, the elastic layer of silicone rubber A, and the release layer made of PFA were laminated in this order.

[0107] The produced fixing belt 1 was fixed on an aluminum cylinder base, heated from the inside with a halo...

Embodiment 2~6 and comparative example 1~3

[0124] Except for adjusting the type of dimethyl polysiloxane having a vinyl group in the side chain, the mixing ratio of various types, the amount of additives, etc., similar to the production based on silicone rubber A, each with silicone rubber B was produced. Fixing belt 2 with elastic layer, fixing belt 3 with elastic layer made of silicone rubber C, fixing belt 4 with elastic layer made of silicone rubber D, fixing belt 5 with elastic layer made of silicone rubber E, fixing belt with elastic layer made of silicone rubber F The fixing belt 6 with an elastic layer made of silicone rubber G, the fixing belt C1 with an elastic layer made of silicone rubber G, the fixing belt C2 with an elastic layer made of silicone rubber H, and the fixing belt C3 with an elastic layer made of silicone rubber I. In addition, in the same manner as the silicone rubber A, various physical properties of the silicone rubbers B to I were measured. In addition, except that the fixing belts 2 to 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com