Direct-pull separated connector

A connector and detachable technology, applied in the direction of connection, parts of connecting devices, devices for connecting/disconnecting connecting parts, etc., can solve problems such as large pulling force, and achieve the effect of easy unlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

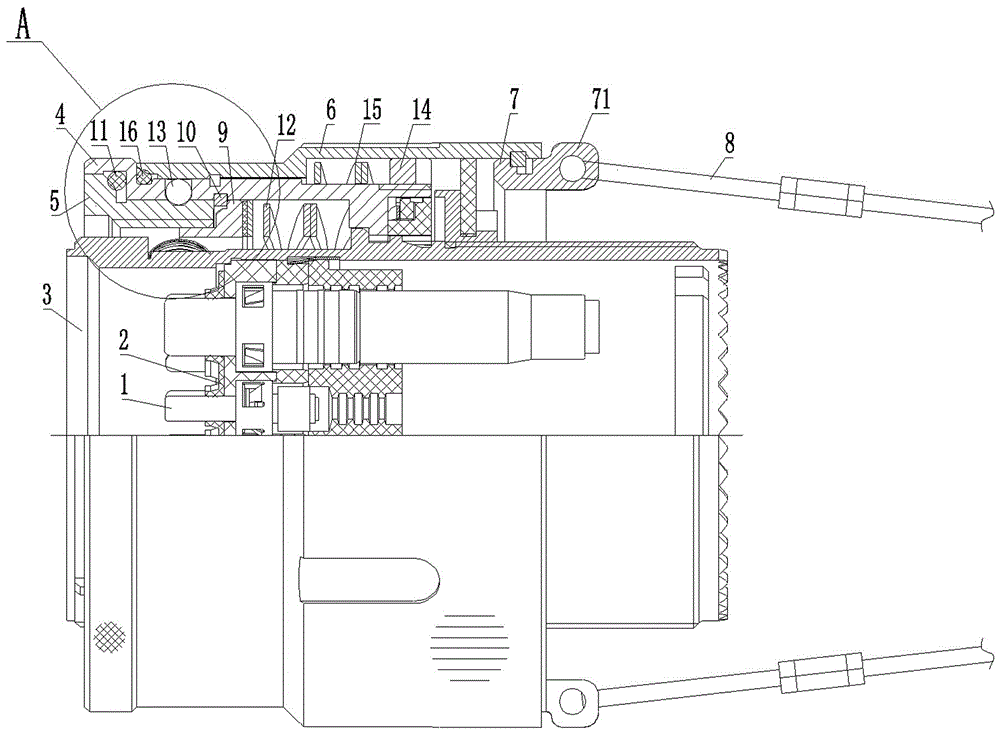

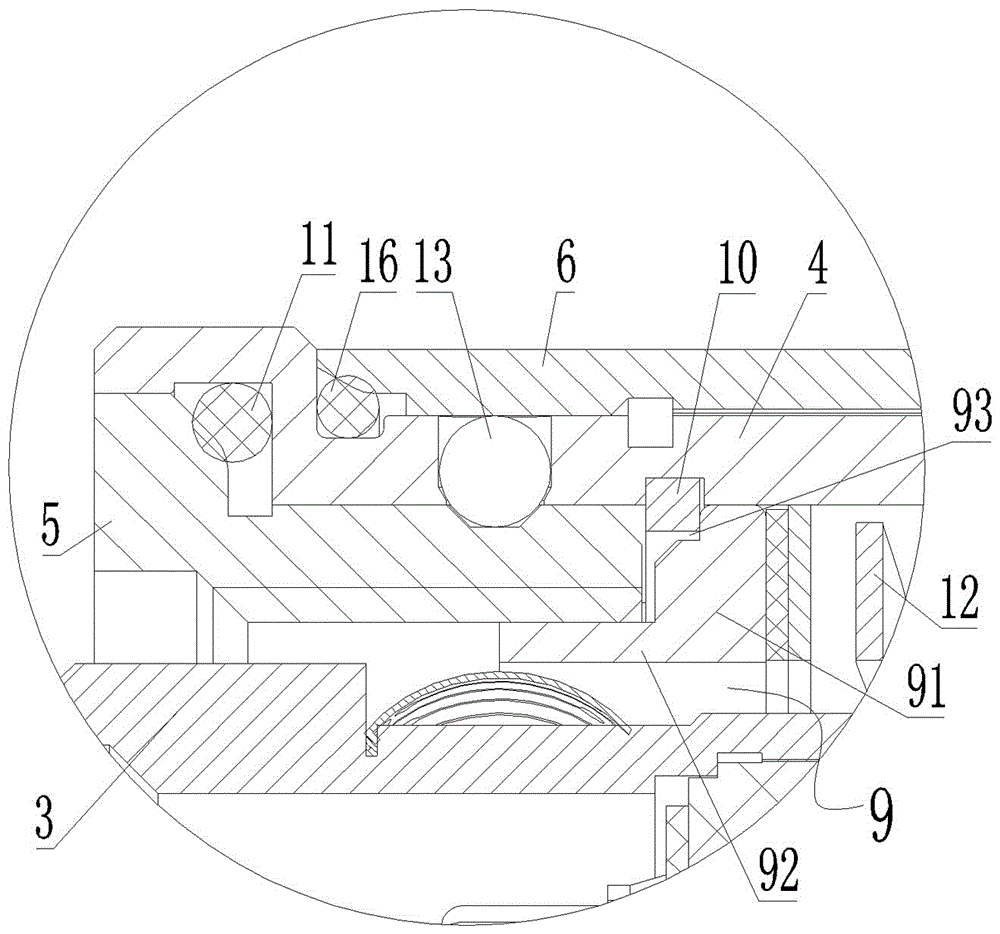

[0025] Embodiment of the pull-cord drop-off connector in the present invention: the connector is a screw-connected straight-pull separation plug with a built-in drive. Under the action of the mechanism, the separation force of the plug is greatly reduced, and the separation force is stable and controllable.

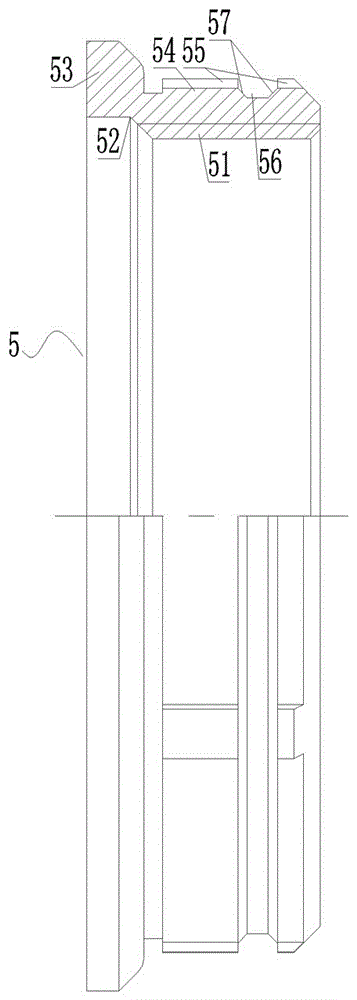

[0026] Such as figure 1 and figure 2 As shown, the plug includes a plug part. The plug part is composed of a contact piece 1, an insulator 2 and a plug shell 3. The contact piece 1 is assembled in the plug shell 3 through the insulator 2, and the plug shell 3 is covered with an axial stopper. Assembled swivel sleeve 4, the swivel sleeve 4 is connected with the threaded sleeve 5 through the inner keyway structure, and the pull-off housing 6 is set on the outside of the swivel sleeve 4 through the outer keyway structure, and the rear end of the pull-off housing 6 is equipped with a rear limiter The pull ring 7 is provided with two symmetrically arranged pull ears 71 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com