Automatic seed and seedling dropping device and control method thereof

An automatic pot seedling technology, applied in planting methods, potato planters, transplanting machinery, etc., can solve the problems of high garlic prices, increased labor costs, and increased production costs, so as to improve the qualified rate of plant spacing and avoid The effect of replay missed broadcast and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the present invention, the fixed plate, the sliding plate and the spacer guide rail supporting plate are made of metal plate or hard plastic plate.

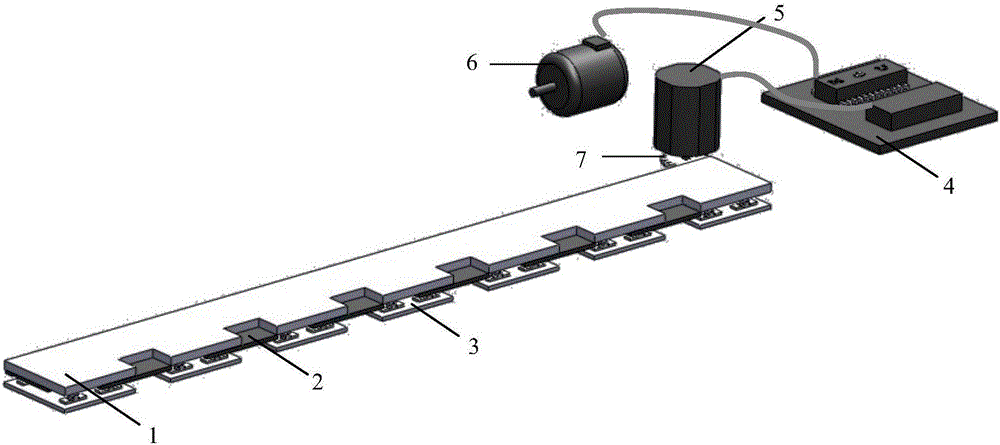

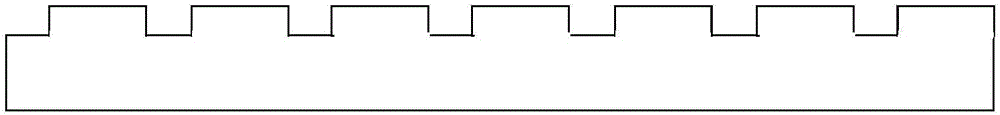

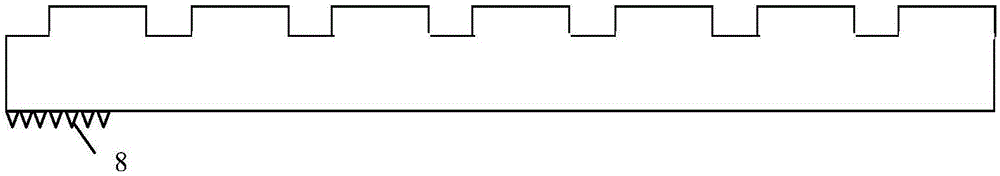

[0026] An automatic seeding and seedling throwing device, the fixed plate 1, the sliding plate 2, and the limit guide rail 3 are stacked and installed up and down sequentially, the fixed plate 1 has rectangular through holes distributed at equal intervals, and the distance between the center lines of adjacent through holes is equal to that of crops. Plant row spacing. The sliding plate 2 is installed below the fixed plate 1, and there is a small gap between it and the fixed plate 1. The sliding plate 2 has equidistant rectangular through holes of the same size as the fixed plate 1. There are two grooves 9 on the bottom surface of the sliding plate 2. One end of the other side opposite to the rectangular through hole is provided with a section of rack 8 . The limit guide rail 3 is located below the slide plate 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com