Pressing mechanism for rotator commutation device

A commutator and rotor technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor accuracy and damage of rotating cylinders, and achieve the effect of reducing force and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

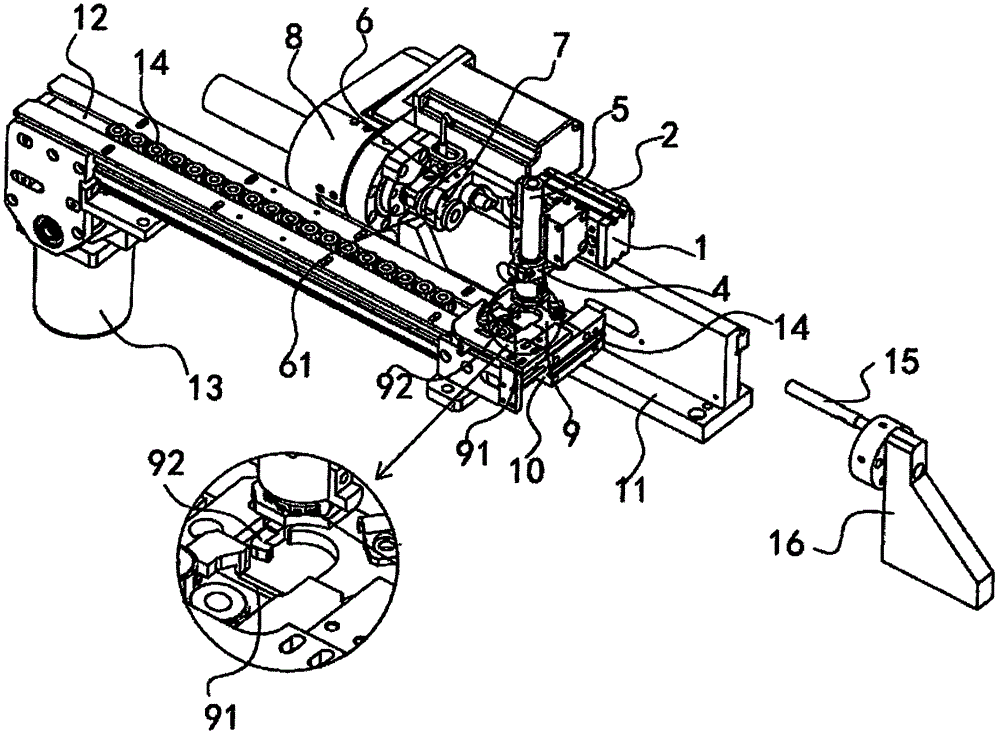

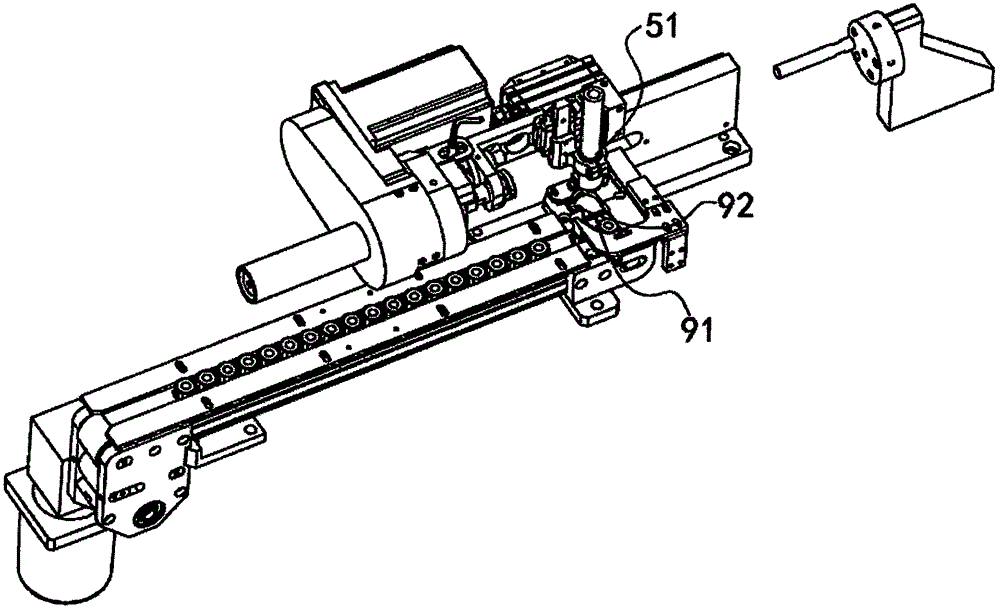

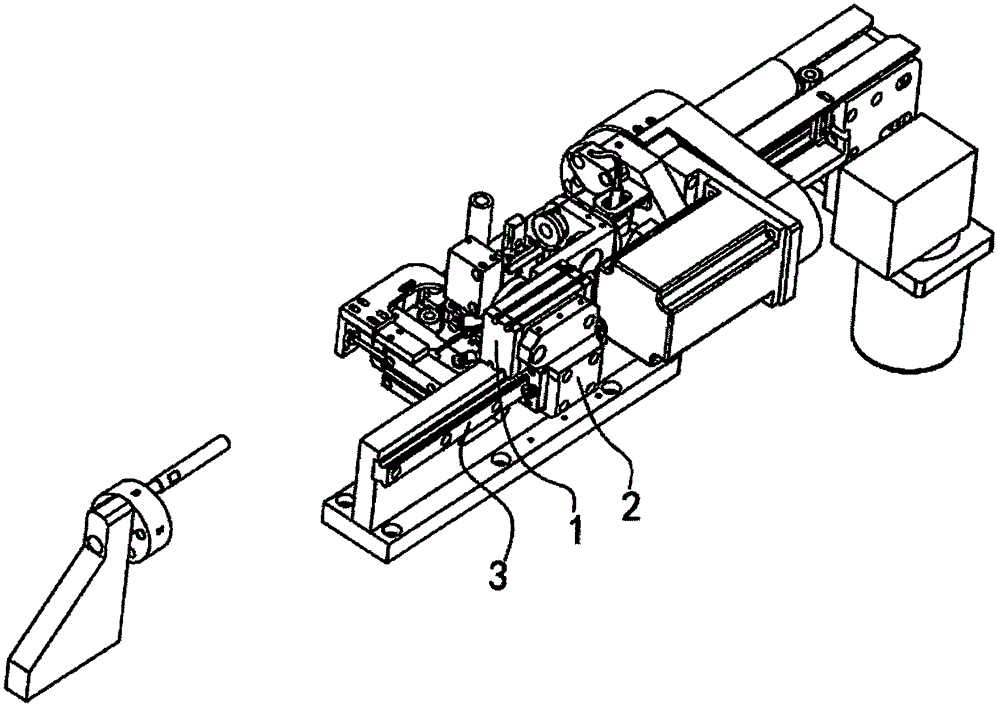

[0020] Please refer to Figure 1 to Figure 4 , the rotor commutator press-in mechanism in the figure includes a commutator grabbing rotary cylinder 1, a rotary cylinder slider 2, a guide rail 3, a pressing rod fixing part 4, a commutator pressing rod 5, a Spacer rod 6, a commutator pressure head 7, a commutator pressure head driver 8, a commutator block 9, a commutator into the block cylinder 10, a base plate 11, a commutator Transport track 12, a commutator transport drive mechanism 13.

[0021] The commutator grabs the rotary cylinder 1, which is a commonly used part at present, and it is a standard part, and a pressing rod fixing part 4 is installed at the position of the rotary head. The commutator grabs the rotary cylinder 1 and is fixed on the guide rail 3 through the rotary cylinder slider 2, and the above-mentioned guide rail 3 is fixed on the bottom plate 11, so that the commutator grabs the rotary cylinder 1 and can be on the above-mentioned slider 2 on the guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com