Burr cutter

A cutting machine and burring technology, applied in metal processing, etc., can solve the problems of manpower and time consumption, shortening the trimming process, manpower and equipment integration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

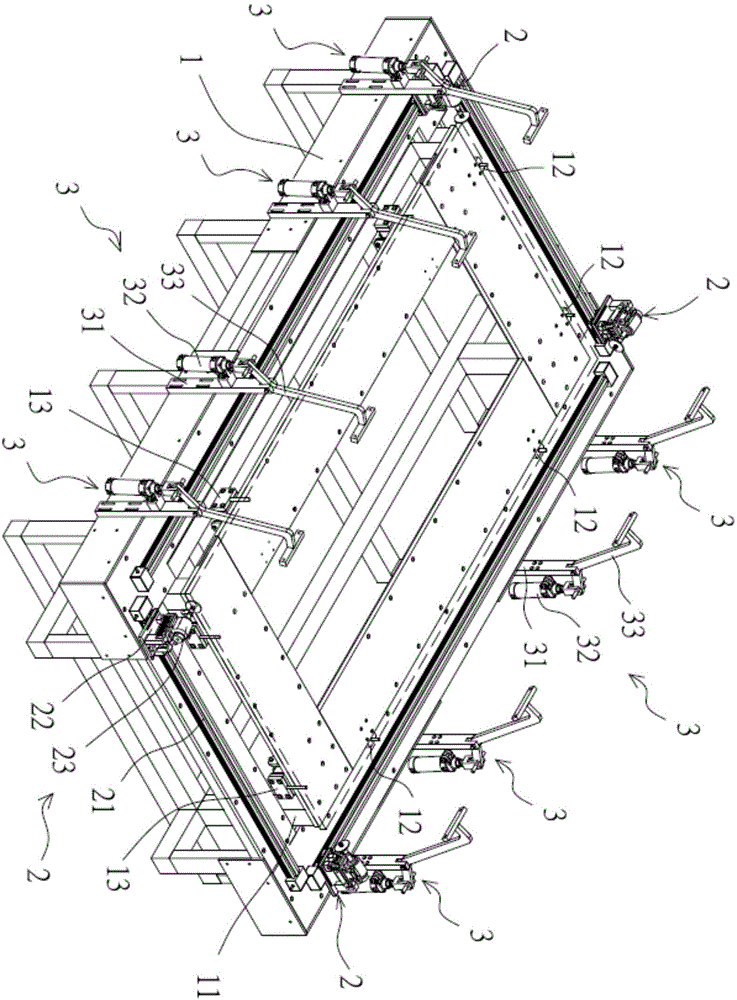

[0035] Please refer to shown in the first to second figures, a kind of raw edge cutting machine of the present invention, comprising:

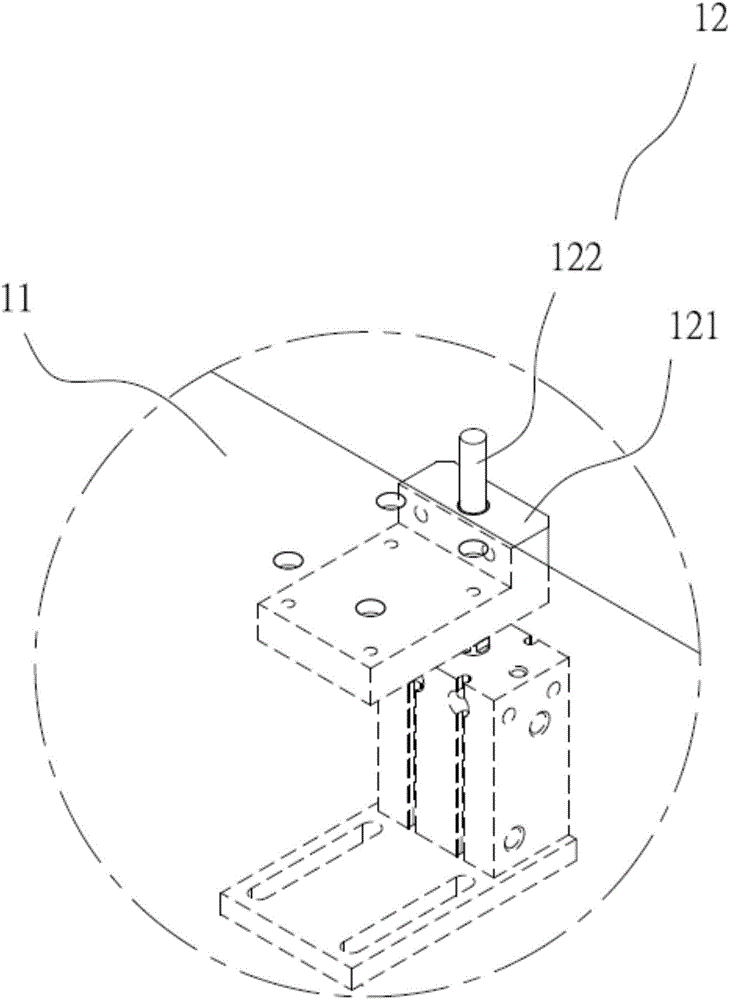

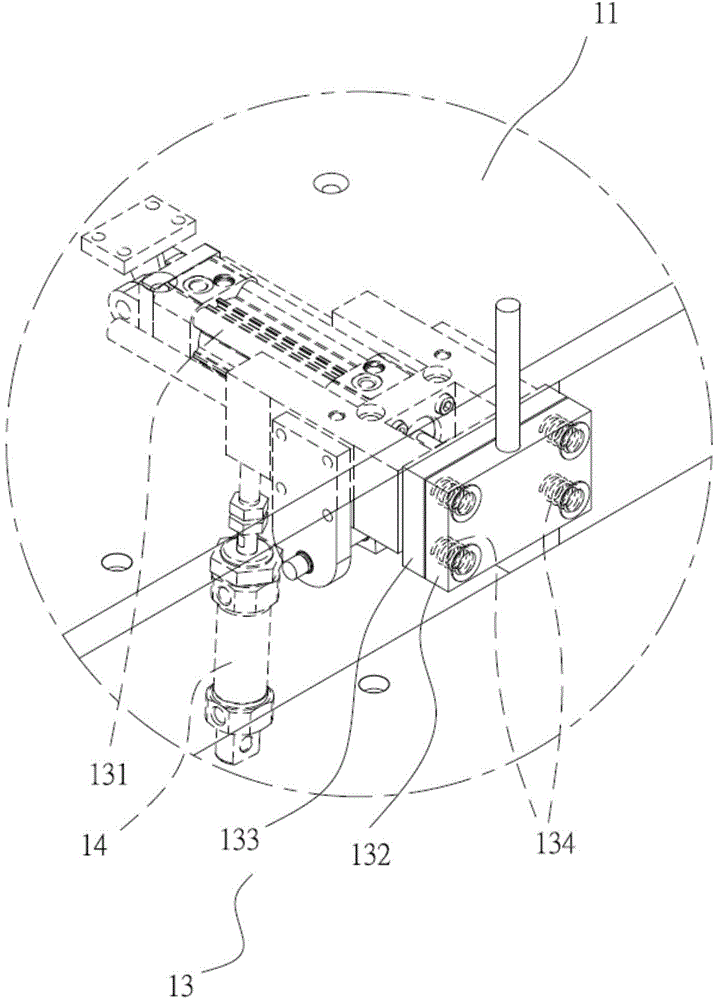

[0036] A body (1) is provided with a platform (11), a fixed positioning device (12) and a movable positioning device (13). The platform (11) is protruded on the body (1), and fixed Positioning device (12), other two sides are provided with movable positioning device (13).

[0037] Four cutting devices (2), each located on the body (1) and at the outer peripheral corner of the platform (11), the cutting device (2) consists of a guide section (21), a base (22) and a The cutter (23) is assembled, the guide section (21) is provided with a base (22), which can be displaced on the guide section (21), and the base (22) is provided with a cutting cutter (23).

[0038] A plurality of pressing arm mechanisms (3) are located on both sides of the body (1), and are composed of a base (31), a pressure cylinder (32) and a pressing arm (33). The pressing ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com