Drilling device used for circuit board

A drilling device and circuit board technology, applied in metal processing and other directions, can solve the problems of low precision and slow drilling speed, and achieve the effects of improving precision, increasing drilling speed, and improving drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

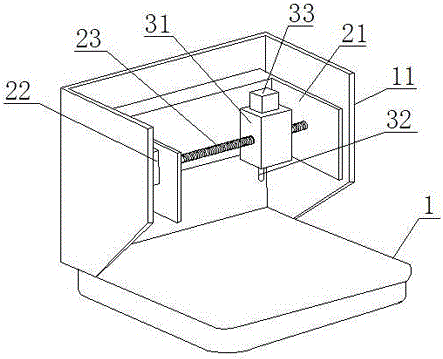

[0021] Such as figure 1 The shown drilling device for a circuit board includes a base 1, a drilling device and a support frame 11 arranged on the base 1, and is characterized in that it also includes a lateral control device and a longitudinal control device;

[0022] The lateral control device includes a bracket 21, a first driving device 22 fixed on the bracket 21 to control the rotation of the screw mandrel 23;

[0023] Described drilling device comprises the fixed block 31 that is threadedly connected with screw mandrel 23, drill bit 32 and is arranged on the fixed block 31 to drive the second driving device 33 that drill bit 32 rotates, and described fixed block 31 is close to the bottom of support 21;

[0024] The longitudinal control device includes a third drive device that pushes the bracket 21 to move in a direction perpendicular to the screw rod 23 , and the third drive device is fixed on the support frame 11 .

[0025] The fixed block 31 is close to the bottom of ...

Embodiment 2

[0027] Such as figure 1 A drilling device for circuit boards shown in the present embodiment is refined on the basis of the above embodiments, that is, the first driving device 22 is a motor.

[0028] The second driving device 33 is a motor.

[0029] The third driving device is a hydraulic cylinder.

Embodiment 3

[0031] Such as figure 1 A drilling device for a circuit board shown in this embodiment is refined on the basis of the above embodiment, that is, the first driving device 22 is fixed on the side wall of the bracket 21, Two opposite side walls of the bracket 21 are provided with screw fixing holes, and the screw rod 23 is penetrated in the screw fixing holes and threadedly connected with the screw fixing holes. The bracket 21 is "U"-shaped, so that the bracket has two opposite side walls, and the screw mandrel is fixed by using the two side walls, which can ensure the stability of the screw mandrel structure, and improve the drilling accuracy and drilling stability of the drilling device sex. The screw mandrel fixing hole is threadedly connected with the screw mandrel 23, and the tight connection between the threads can improve the fixing stability of the screw mandrel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com