Safety tension device of automatic belt rollback vehicle

A technology of automobile safety and tensioning device, which is applied in the directions of motor vehicles, transportation and packaging, and vehicles for freight transportation, etc., can solve problems such as troublesome operation, and achieve the effects of simple structure, good practicability, and quick and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

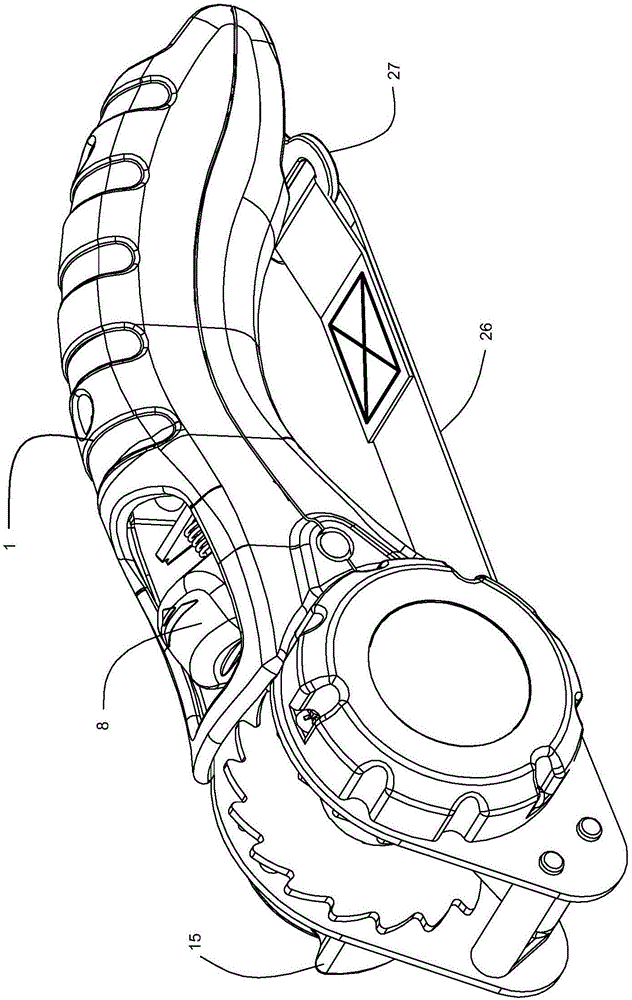

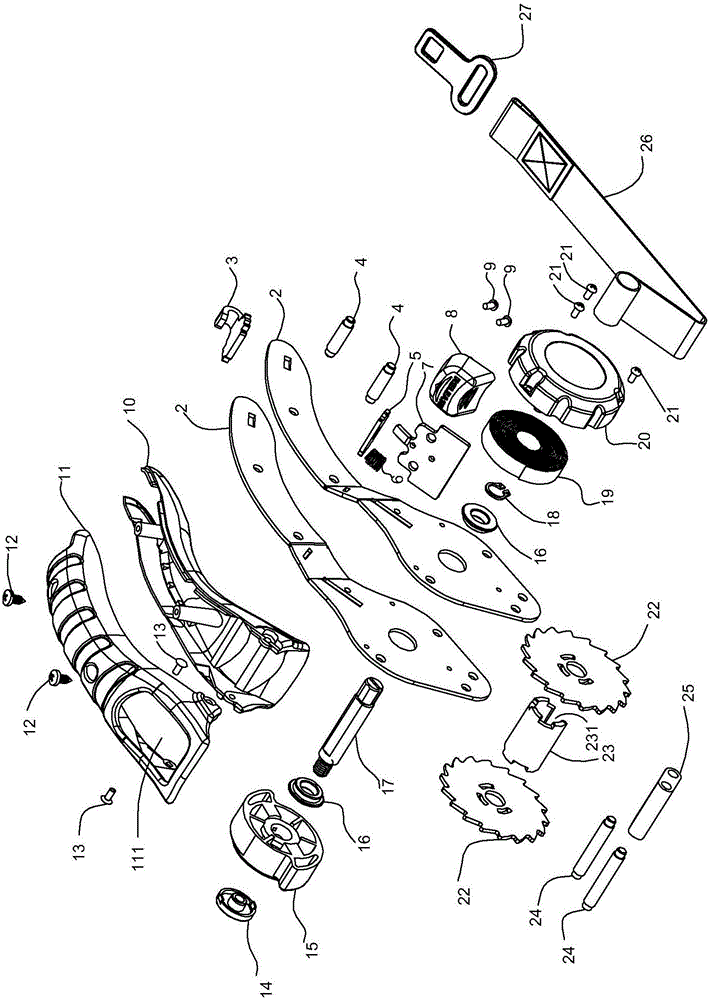

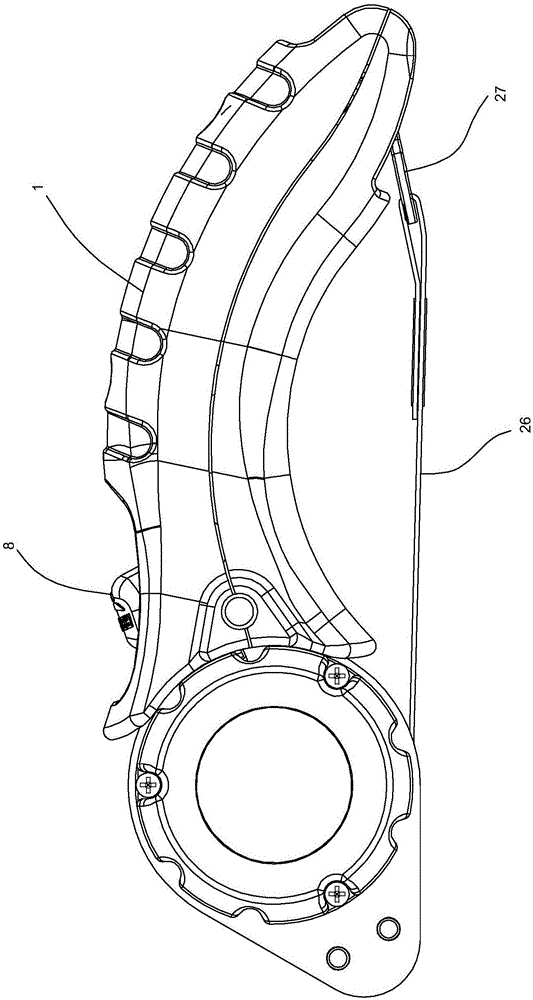

[0021] combine Figure 1-Figure 7 As shown, the automatic take-up car safety tensioning device mainly includes a handle, a coil spring shaft 17, a take-up reel, a take-up device, a stop pawl assembly, a knob 15, a ribbon 26, etc., wherein:

[0022] The handle includes left and right side plates 2 with the same structure, and the two side plates 2 are connected into one body through several connecting shafts 4 . The rear part of the handle is covered with a casing to facilitate holding and increase hand comfort. The casing is combined with an upper cover 11 and a lower cover 10 and then connected into one body through screws 12 and rivets 13 types of connectors, and the top of the upper cover 11 is also provided with an opening 111, so that Button 8 is exposed outside. In addition, a hook-like hook 3 is connected between the tails of the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com