Cargo box decoration bar

A decorative bar and cargo box technology, applied in the field of cargo box decorative bars, can solve the problems of no wire take-up device, manual wire take-up, time-consuming and labor-intensive, etc. for the cargo box decorative frame, and achieves the effect of avoiding the difficulty in arranging the binding wires and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

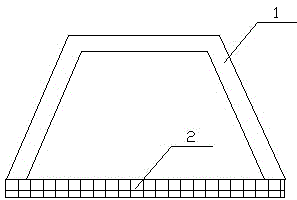

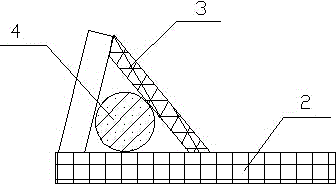

[0010] like figure 1 , 2 As described above, a cargo box decorative bar includes an isosceles trapezoidal decorative plate 1 and horizontal decorative bars 2 installed at the bottoms of the left and right ends of the isosceles trapezoidal decorative plate 1, and oblique decorative bars are arranged on both sides of the isosceles trapezoidal decorative plate 1 3. An automatic winding disc 4 is provided between the inclined decorative bar 3 and the isosceles trapezoidal decorative plate 1, and the automatic winding disc 4 is fixed on the decorative bar by welding. The setting of the automatic winding reel 4 can not only replace the manual winding work, but also avoid the loss of the coil.

[0011] The improved decorative bar of the cargo box realizes automatic wire take-up, which saves time and effort, avoids the trouble of difficult tidying of wire tying, and improves the efficiency of loading and unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com