Grinding wheel cutting machine capable of realizing forwarding cutting

A grinding wheel cutting machine and grinding wheel technology are applied in the direction of grinding feed movement, grinding machine tool parts, grinding machines, etc., which can solve the problems of not being able to cut various types of square tubes and affect the cutting efficiency of workers, so as to save energy , Safe to use and labor-saving to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

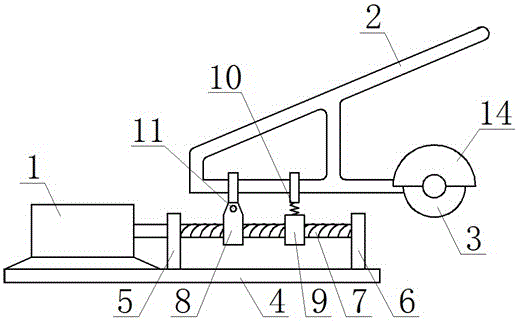

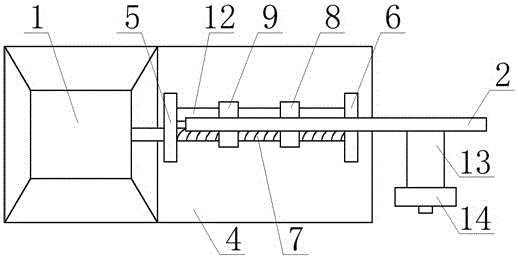

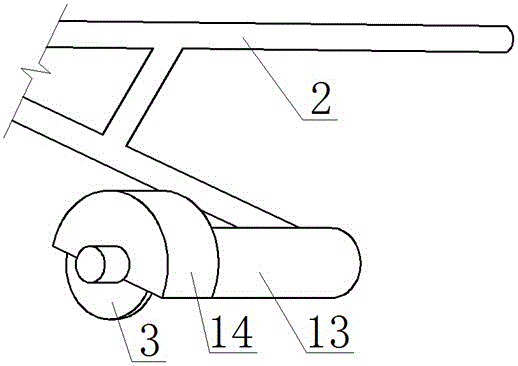

[0022] An abrasive wheel cutting machine capable of advancing cutting, such as Figure 1 to Figure 3 As shown, it includes a base 4, a drive motor 1 mounted on the base 4, a grinding wheel 3 and a screw 7, the base 4 is also provided with a support 5 and a b support 6, and the screw 7 runs through the a support 5 and the b support 6, and is connected with the rotating shaft of the driving motor 1, on the screw mandrel 7 is provided with an operating rod 2 connected by thread, and on the operating rod 2 is provided with a grinding wheel motor 13, so The grinding wheel 3 is installed on the rotating shaft of the grinding wheel motor 13.

[0023] Described screw mandrel 7 is connected with the rotating shaft of driving motor 1, and when driving motor 1 rotates, screw mandrel 7 rotates with the rotation of driving motor 1 rotating shaft, and operating lever 2 is connected with screw mandrel 7 by screw thread, when screw When the rod 7 rotates, it can drive the operating rod 2 to ...

Embodiment 2

[0025] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1 to Figure 3 As shown, further, the screw rod 7 is threadedly connected with a bearing support 8 and a spring support 9, and the operating rod 2 is connected with the bearing support 8 through a shaft pin 11, and is connected with the spring support through a spring 10. 9 phase connections. When cutting materials such as square pipes, round pipes, special-shaped pipes, steel bars, etc., the staff can press down the operating lever 2 so that the grinding wheel 3 can quickly cut the material. Resetting under action is beneficial to the next cutting work.

Embodiment 3

[0027] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1 to Figure 3 As shown, further, the bearing support 8 is close to the side of the drive motor 1, and the spring support 9 is close to the side of the grinding wheel 3. 1 side, the distance between the bearing support 8 and the staff's hand is the largest, so that the staff's arm of force is the largest and the active force is the smallest, which helps to save the staff's physical strength and makes the use of the present invention more labor-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com