Novel automatic kitchen waste collecting and transporting system

A new type of technology for food waste, which is applied in the field of new automatic collection and transportation system of food waste, can solve the problems of imperfect system, small net weight value, incomplete balance of rear wheels of heavy vehicles, etc., and achieve the goal of avoiding cheating in weighing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

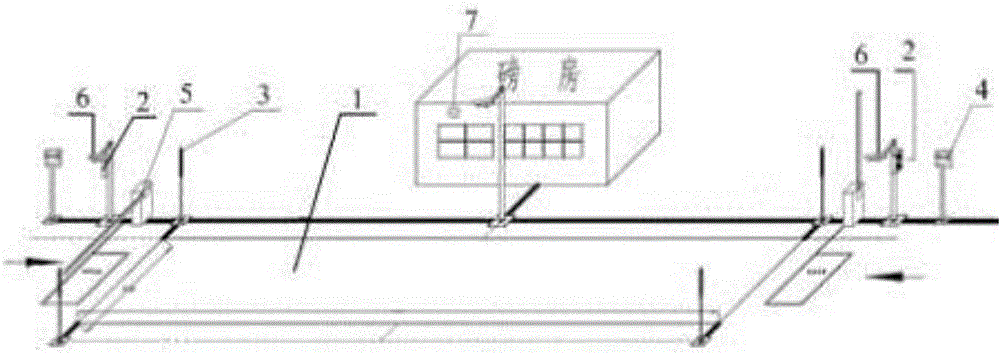

[0019] A new type of automatic food waste collection and transportation system includes a control management system, a vehicle-mounted terminal system, and an unattended weighing system. The kitchen waste transport vehicle collects kitchen waste, and the on-board terminal system reads the electronic identity of the trash can, and transmits the identity information to the control management system through GPS. The control management system counts the collected identity information and calculates the garbage cans collected The number of barrels; the kitchen waste transport vehicle weighs through the unattended weighing system, and the unattended weighing system transmits the weighing information to the control management system through the transmission network; the unattended weighing system includes computer control modules, Truck scale, smart card identification module, barrier gate, video monitoring module, infrared monitoring module and voice command module, the smart card id...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com