Movable material picking mechanism for products

A technology of reclaiming mechanism and products, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of poor use effect, slow action process, difficult to control, etc., to increase flexibility, adaptability, fast action and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

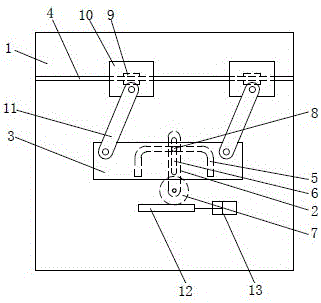

[0008] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0009] figure 1 It shows the product moving and retrieving mechanism provided by the present invention, including a vertical plate 1, a vertical swing bar 2 located on the back of the vertical plate 1, a clamping claw mounting plate 3 located on the front of the vertical plate 1, and fixed on the upper front of the vertical plate 1 The horizontal slide rail 4 of the vertical plate 1 is provided with a chute 5 on the surface of the vertical plate 1, and the chute 5 is in an inverted U shape; the upper part of the swing rod 2 is provided with a vertical strip hole 6, and the lower end is provided with a drive shaft. A gear 7 is fixed on the top, and the gear 7 is equipped with a rack 12 meshing with it; the rack 12 is connected with a cylinder 13 that drives it to reciprocate, and the rack 12 is equipped with a guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com