Proving ring of load lifting limiter

A technology of lifting weight limiter and force measuring ring, which is applied in the direction of clockwork mechanism and hoisting device, can solve the problems of springback error, deformation coefficient, glue falling off and pressure block aging, etc., and achieves easy production and good structure Reasonable and easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

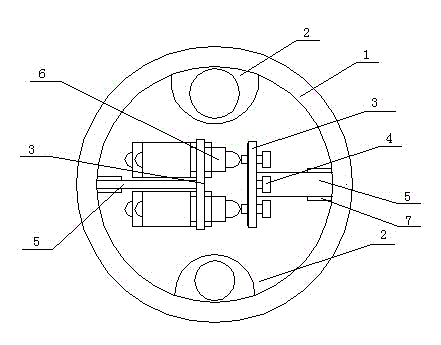

[0008] Two connecting sleeves 2 are welded on the inner side of the ring 1, and the fixing plate 7 is welded on the inner side of the other opposite side of the ring, and the connecting line of the two connecting sleeves is perpendicular to the connecting line of the two fixing plates. Install the connecting plate 5 and the mounting plate 3 on the two fixing plates 7 respectively through the connecting screws, respectively install four micro switches 6 and the adjusting screws 4 on the mounting plate 3, and pass the anti-loosening screws on the mounting plate where the adjusting screw 4 is installed. Install the anti-loosening plate, and the micro switch and the adjusting screw correspond to the same center line. A cover plate is arranged on the ring, and the shape of the force measuring ring is like a round cake. When installing and adjusting the force measuring ring, adjust the adjusting screws separately to achieve the purpose of alarming and power off, and then tighten the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com