A damage identification method for lightweight high-strength beam structures

A technology for structural damage and damage identification, applied in the direction of strength characteristics, using stable bending force to test the strength of materials, instruments, etc., can solve the problems of fine damage accumulation and achieve the effect of accurate damage parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

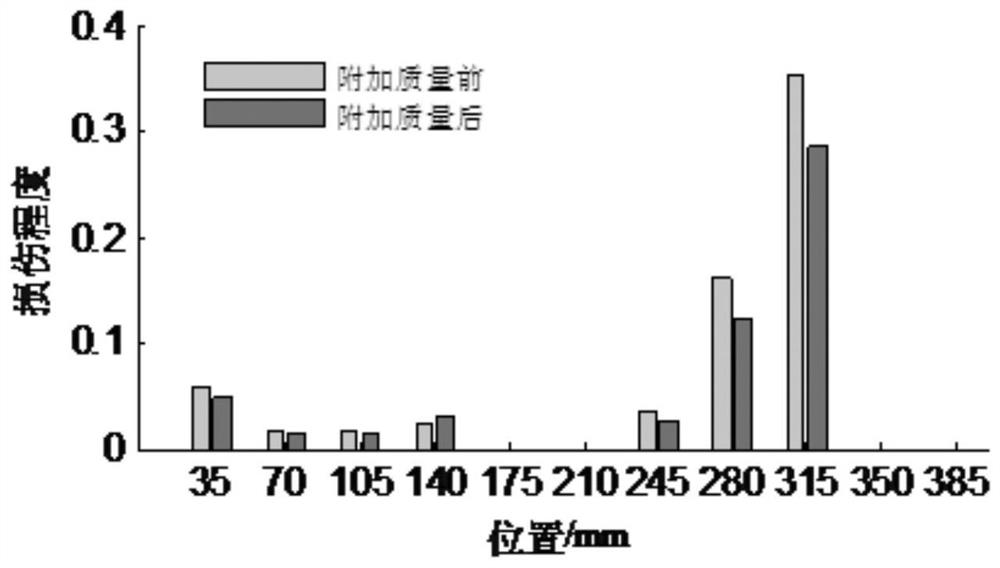

[0052] In order to further illustrate the method of the present invention, the present embodiment 1 is compared with the calculation results of the frequency sensitivity method before and after adding mass,

[0053] The specific calculation steps of the present embodiment 1 are as follows:

[0054] Step (1): adopt the physical parameter (seeing table 1 below) of the beam structure used in the foregoing embodiment:

[0055] Table 1 Physical parameters of the beam structure

[0056]

[0057] Step (2): Determine the physical parameters of the beam structure, arrange acceleration sensors on the beam structure for modal analysis, figure 1 with figure 2The beam structure specimen and the arrangement of acceleration sensors are given. According to step (5) in the summary of the invention, the low-order modal parameters before and after the structural damage before the added mass are obtained; according to the step (6) in the summary of the invention, the low-order modal parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com