LED test device and test method

A test device and a technology to be tested are applied in the direction of measuring devices, single semiconductor device testing, and electrical measurement, which can solve problems such as LED light intensity errors and achieve accurate light intensity and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

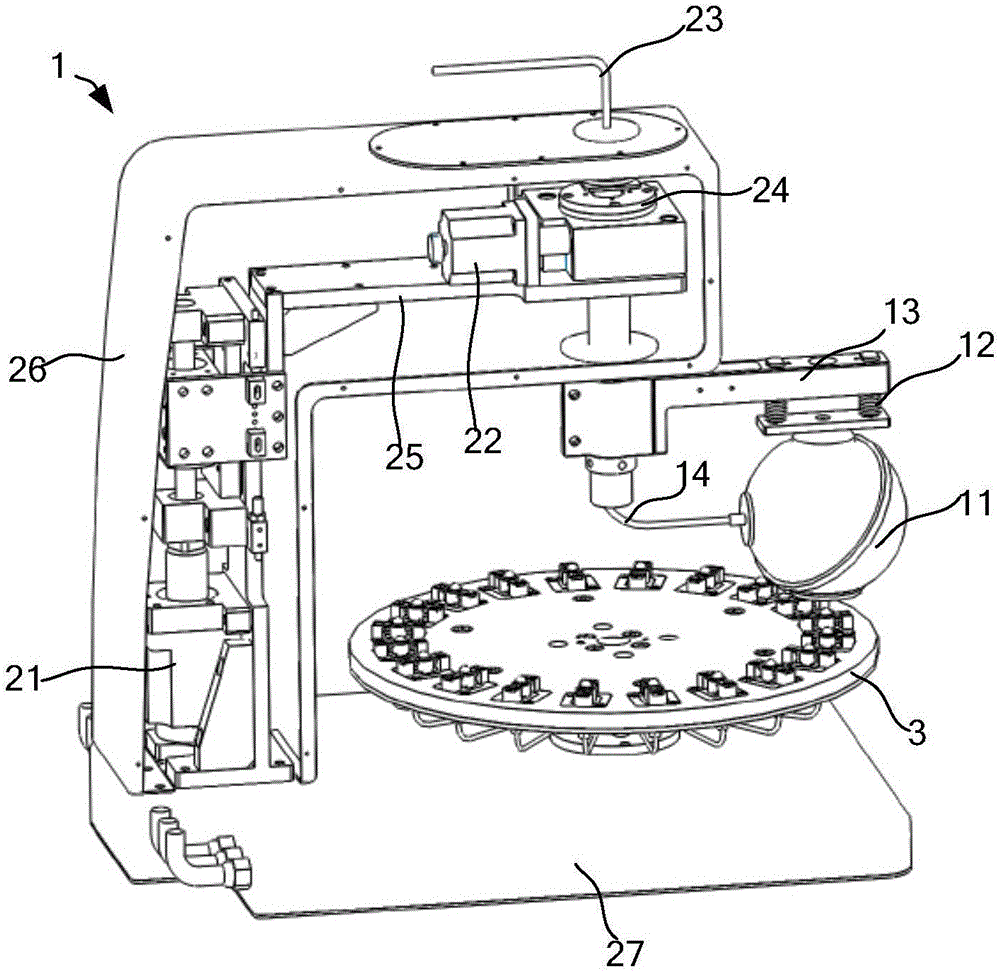

[0032] The preferred embodiments of the invention will be further described in detail below.

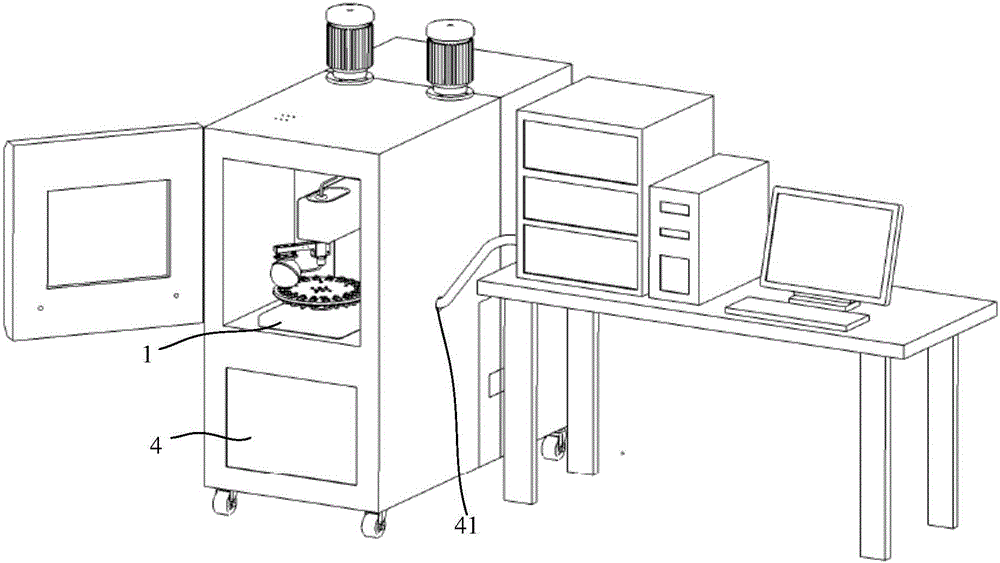

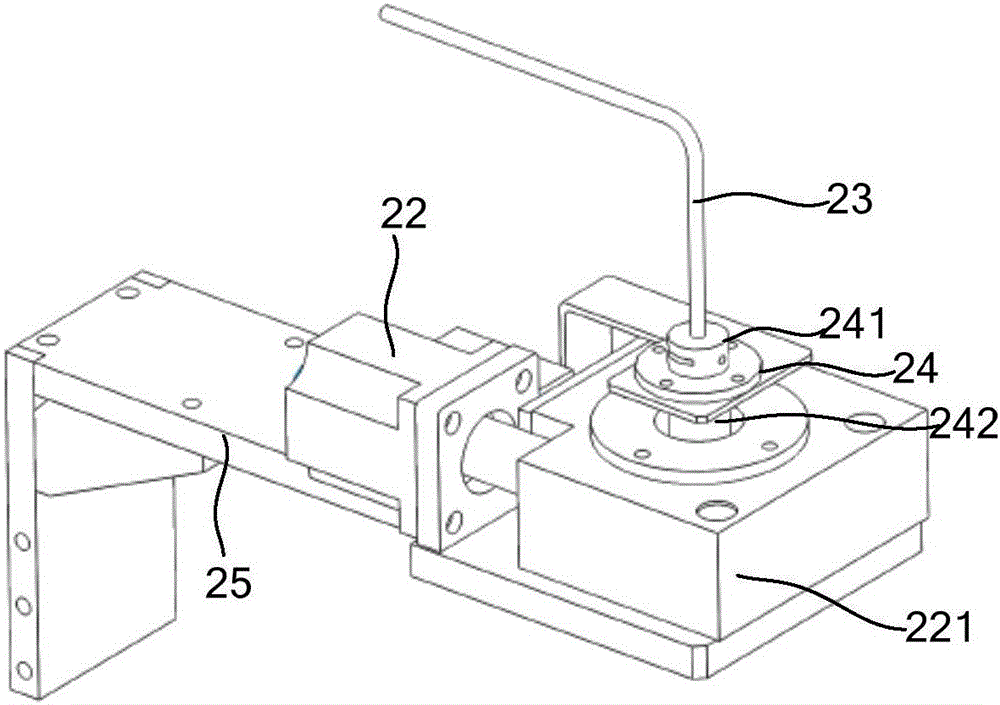

[0033] Such as Figures 1 to 6 As shown, the LED test device 1 of an embodiment includes a lifting drive device 21, a rotary drive device 22, an integrating sphere 11 and an integrating sphere tilt angle adjustment component 12, and the rotary driving device 22 is used to drive the integrating sphere 11 Rotate to align the tested LED 31 , the lifting drive device 21 is used to drive the integrating sphere 11 to approach and cover the tested LED 31 and away from the tested LED 31 . The integrating sphere 11 can be made of high temperature resistant material.

[0034] Normally, a plurality of tested LEDs 31 are fixed on the LED fixing plate 3. Due to other reasons such as installation, it is difficult to ensure that the position of the LED fixing plate 3 is horizontal, and the angle of the LED fixing plate 3 after each disassembly and installation It may also be different. Similarly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com