A kind of edging machine with the function of removing film

An edge grinding machine and functional technology, applied in machine tools, grinding machines, manufacturing tools and other directions suitable for grinding the edge of workpieces, can solve problems such as difficulty in grinding, peeling of insulating glass sealant, and shortening of the service life of insulating glass. Simple structure, improved product quality, convenient and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

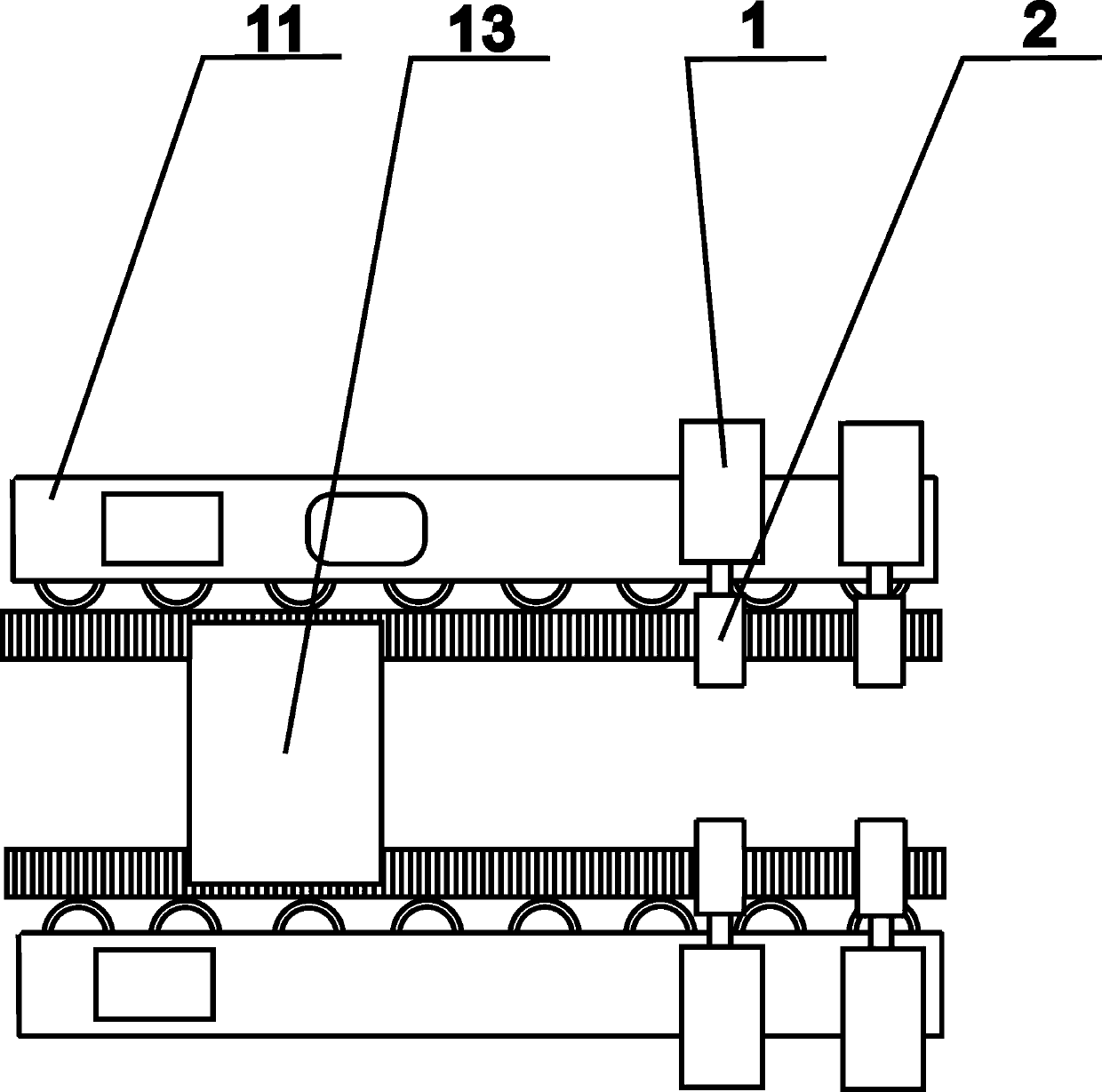

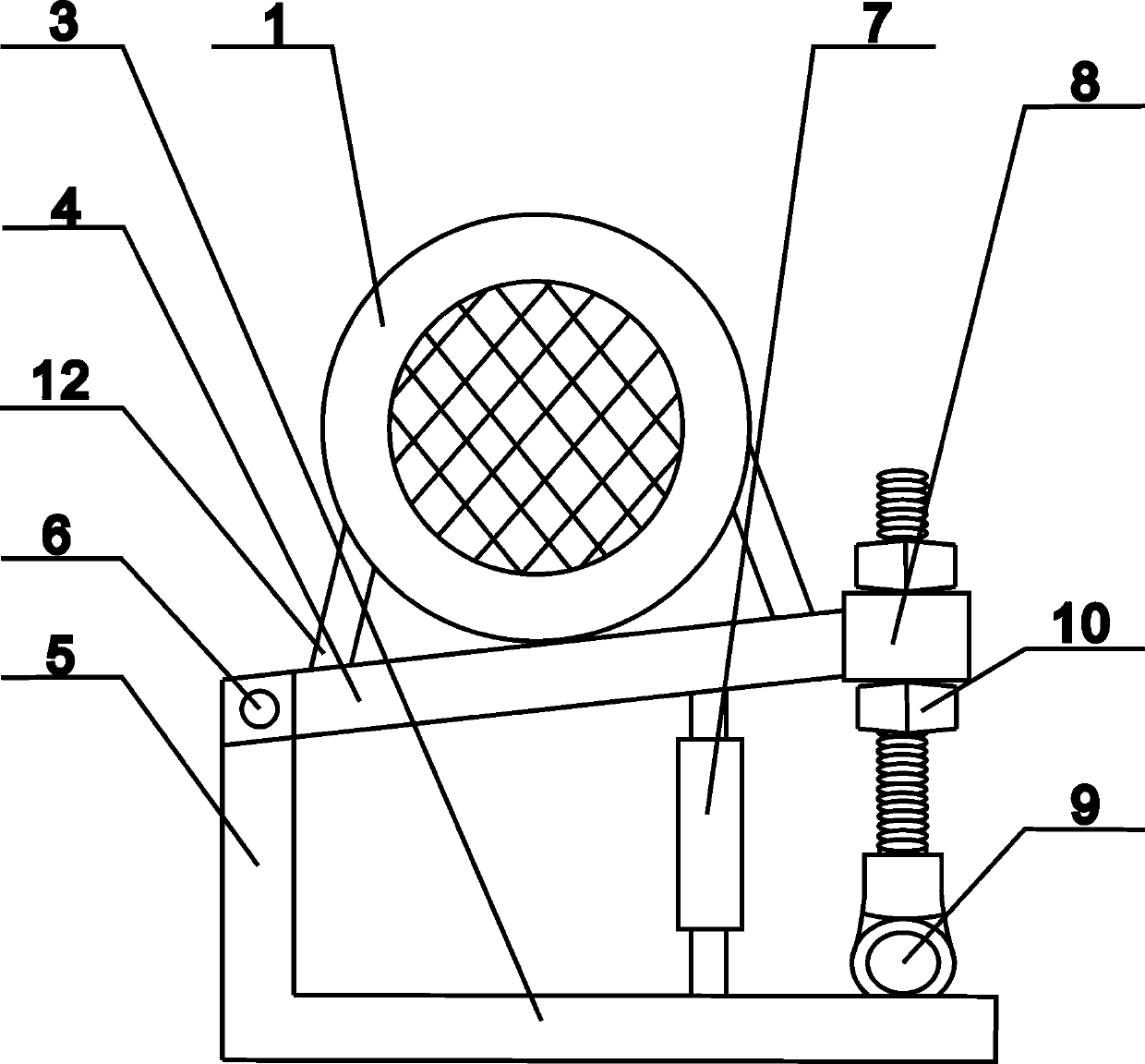

[0021] As shown in the figure, an edging machine with the function of removing film includes a motor 1, a grinding wheel 2, and an adjustment device 3; Two are arranged on the bottom of the edging machine 11, and the end of the power output shaft of the motor 1 is fixedly provided with a grinding wheel 2; Composed of cylinder 7, positioning bolt 8, movable shaft 9, fastening nut 10, reinforcing plate 12, transverse support plate 4 is provided with two, one is fixedly arranged on the bottom of motor 1, and another piece is arranged on the bottom of cylinder 7, and parallel The cylinder 7 is fixedly connected, and a vertical support plate 5 is arranged on the left side between the two transverse support plates. The side position is fixedly provided with a positioning bolt 8, which is fixed by a fastening nut 10, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com